EuroLine Windows is a proudly Canadian manufacturer of high-performance windows and doors based in Delta, British Columbia. Their products include folding doors, tilt & glide doors, lift & slide doors, smart slide doors, tilt & turn windows, high-performance casement windows, and their PHI-certified 4700-series ThermoPlus windows and doors. They have gained a reputation for crafting windows and doors that combine innovative engineering, sophisticated design, and craftsmanship, creating products that allow developers and architects to achieve exceptional levels of performance without sacrificing on aesthetics.

EuroLine’s President, Davyd Funk, recently sat down with Passive House Accelerator to discuss the firm’s unique approach to fenestration. Originally from Toronto, Funk has worked in residential home improvement for the vast majority of his career and became President of EuroLine Windows three and a half years ago.

Passive House Accelerator: When was EuroLine Windows founded?

Davyd Funk: 1993. This is actually our 30th year. We're about to have a big celebration here in August with our whole team. It’s a very cool time to hit 30. In fact, we still have some of our first employees here, which is incredible.

PHA: That’s great. Did you begin building high-performance windows right from the start?

Funk: Yes, it was always high-performance. Fabricating a European tilt and turn window in Canada was basically the starting point for the company. Looking over at Europe, it was like, "These are the best windows. Why aren't they building them here? Why is everything that's high-performance imported?" We started small with six or eight employees, and the tilt and turn was the founding product. British Columbia was right for that technology since it's such a moderate climate.

We’ve since grown. We now have EuroLine design consultants throughout Canada and the US, as well as three showrooms in B.C. and one in Toronto. In B.C., we have one in Kelowna, which is in the interior; one on the island near Victoria; and then we have the one here at our factory, in Delta, which is only 25 minutes from Vancouver. It's actually our biggest showroom. The Toronto showroom that we've recently opened up is in the Yorkville area, which is a design district, and it is very close to architects and design firms, so we can bring them in and show them our products. We also have a few small popups where we have product installations across Canada and the US with some of our partners.

PHA: A lot of the materials that ultimately make up the windows are imported from Europe. Is that efficient?

Funk: There's an ongoing debate around this point, but it was part of the reason why EuroLine Windows was founded. If we are going to bring over the finished windows for a house, those windows could potentially take up a whole container on a ship. However, we can bring 10 to 12 houses worth of material in one container because we're bringing them as flat profiles all stacked together, and then we're manufacturing the windows here. We’re bringing the customization side closer to where it's actually going to be installed. Moreover, we reduce the number of trips across the ocean from 12 to one.

It would be terrific if Rehau, Aluplast, Cortizo, or any other European company was actually fabricating in North America, but that's just not what's happening. So, we have to go and get the best materials, and then figure out a way to get them to market the most efficiently. We believe bringing raw materials here and manufacturing locally is the way to do it.

PHA: Is the glass manufactured here or in Europe?

Funk: The glass is local. It's float glass laid up in the Pacific Northwest of the U.S. Then, the IGUs [insulated glass units] are made in Langley, which is 30 minutes away. We’re getting deliveries daily and try to keep it in a circle. Anything from screws to glass—all that stuff should come as local as possible.

PHA: I’d like to switch gears a bit from manufacturing to sales. To start, how do you make the process of buying windows a little easier for homeowners, builders, and architects?

Funk: It is complex. Building codes put pressure on the homeowner, the builder, and the architect alike, and it takes time to demystify the buying process. You should visit our showroom or meet with our design consultant because we need to show you all the products. We have to explain them to you in great detail because, since windows and doors are made custom, you need to understand how the different elements work together—things like gaskets, IGUs, spacers, and hardware. There are a lot of potential combinations depending on your desired design aesthetic and performance goals, so this work is best done in person. Our design consultants know how to talk to people about product in great detail to help clients achieve their fenestration vision. It's all about education, really. If we can teach you about the window and why it performs well, then eventually that becomes your own narrative. Whether you buy from us or from someone else, we just want to make sure you're making an informed decision.

We try to make our showrooms as accessible as possible because we believe it's critical that our customers come in and spend time with us. We want you to understand what you’re buying since you're making an $80,000 to $150,000 investment in fenestration products. We don't want you to take it lightly.

We also partner with your energy advisor and make sure they know why we're specifying what we're specifying. There’s more than just meeting a certain U-value at all costs. There are trade-offs. What way does the house face? Do you have any shading? There's a whole design discussion that has to go on beyond just the windows, and you can absolutely over spec and give somebody a product that's beyond what they require. That is a disservice because they just paid more than they needed to. This is not our approach as a company. We want you to get what is going to work properly for your goals and your situation.

PHA: As building codes have changed and continue to require more energy-efficient buildings, what is EuroLine Windows working on to improve performance?

Funk: We are always looking for small, incremental gains. The casement window that we have is really popular in North America, and we’re figuring out a way to get that to perform even better. One way we’re doing that is to take the steel out of it. We have worked with one of our partners, Rehau, to develop a hybrid material with fiberglass in the uPVC [unplasticized polyvinyl chloride]. We soft-released it last year, and we are starting to get some uptake on that.

What it allows us to do is to get close to that triple-pane level of performance with only double-glazed glass, where you have a 0.25 U-value or lower. As a result, homeowners, builders, and architects enjoy receiving those cost savings and performance efficiency. There is always an option to choose triple-glazed casement to achieve Passive House level, too.

PHA: What are some of the improvements that you're anticipating EuroLine Windows will make in the future?

Funk: We’re thinking more about our materials and our products, and we’re asking ourselves questions like: What are they made of? What's the origin of those materials? What's the carbon embodiment of each product? How do we recycle them? How do we put them back into the manufacturing flow?

Taking steel out of a window helps, but we’re making sure that we're not replacing it with something that isn't recyclable. Fiberglass is not easy to recycle. Once you embody it into uPVC, it almost becomes waste. This is why we started working more with a company in Europe, Aluplast, who found ways to put stiffeners in windows that are isolatable so you can easily separate them later and recycle the rest of the window.

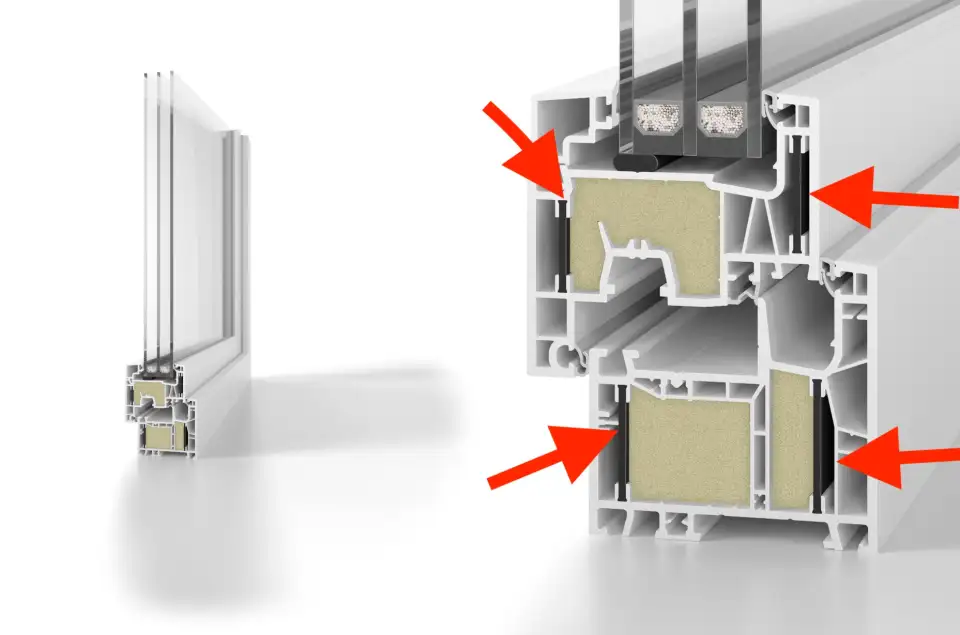

I'll show you (see Figure 1). If you see the black from the white—the black are stiffeners. These are hardened plastic reinforcements. Because they're not blended in with the entire window, they can be cut out when the life of the window has expired. The rest of this uPVC can be recycled, and it's specifically colored differently for that reason. You get the thermal performance you want, but you don't lose the recycling aspect.

The other material that we are really interested in is aluminum. It's already stiffer than uPVC, so we can make these larger elements with it. Customers are interested in recycling and embodied carbon, but they're also interested in aesthetics. They want these massive openings so they can have these great views, but building codes are putting pressure on them to hit certain U-values and thermal performance metrics. Our job is to try and figure out a way to navigate through all of that and provide a suite of products that are going to mix because I want EuroLine Windows to provide the entire house package solution, not just one or two parts of it.

PHA: What’s your most popular door and window models right now?

Funk: For doors, it’s the smart slide product. It's like a tilt and glide door that is easier to operate. The tilt and glide door can sometimes be difficult to handle—to close it and make it fit back into the hole. The smart slide moves in a silky-smooth motion as it slides along its own track. When you turn the handle, it sucks it into the opening to create an excellent performing seal. This high-performance sliding door with smooth operation has become very popular.

More people are considering the benefits of tilt and turn windows these days and designing them into projects. You cannot beat the insulation from that design and the tilt ventilation feature is so useful.

PHA: Do you believe these products will also be useful in projects where historic preservation is a priority? Will these new technologies be able to mimic the aesthetics of historic windows?

Funk: For historic preservation, you need a window that's going to look right, but at the end of the day it also has to perform. Otherwise, you're not really improving the building envelope. Getting the appearance right is a bit of an obstacle, but one of the ways we overcome that is through the use of foiling. Foiling is a method of permanently fusing uPVC foil with the profile that never cracks or needs maintenance, unlike paint or actual wood. It allows you to do more than just add color. You can achieve really unique textures or graining, so the appearance you envision can be achieved whether it's actually made of uPVC or aluminum. We can foil all profiles so that when you're looking at your window from the outside, from the streetscape, it's going to absolutely look like it's oak or walnut or pine or whatever look you need. We can also mimic the internal grid patterns and SDLs [simulated divided lights] found on historic homes.

PHA: How do you help customers make the right choice in terms of framing material?

Funk: We're open-minded. We know there's lots of other materials out there. Wood, for example. It’s not a product that we sell, but there’s nothing wrong with it. Fiberglass is another material. They all have their benefits. We just want to make sure that you understand how our materials work.

It does come back to the in-person appointments. When I show you the profile of a window, I'm going to point out how thick it is. You're going to hold it in your hands and see how heavy it is. To me, it's more about trying to get you to really understand why the material choices we've made make sense and why they are so vital to thermal performance.

PHA: Once they leave the showroom, do you help builders with the installation?

Funk: Yes. More than 90% of what we sell, we install. And I'm really glad you brought that up. It's actually pretty critical. It's like the best defense is a good offense.

I can sell a fantastic window package to you; but, if it's not installed properly, it will not perform as intended, and you're going to think it's the window package. To make sure there’s no failure due to installation, we believe that it is important to interface it with the building ourselves—or to advise builders on the things that must be done. We are 100% behind that.

I think it's very important that we try to impress upon all our clients how critical installation is. Every detail is important. Even simple things like installing level and plum or making sure that the whole thing sits in the opening depth wise, as it was intended can be easily overlooked and have a tremendous effect on performance.

PHA: Any future-forward thoughts about the industry in general? Where do you think fenestration is going in North America in the next 5 to 10 years? Do you think more states and provinces will follow B.C.’s lead?

Funk: Yeah, I do think so. It's helpful because progressive B.C. building standards are providing a tailwind for us. They are speaking the same language we're speaking, and now it's all about getting our customers to appreciate the long-term benefits of building high-performance homes. All of it really makes tremendous sense.

What's interesting is the whole discussion around solar heat gain, which is something that some people misunderstand. Using the sun to heat your house can really be a dangerous thing, and we want to be very careful about that. Sometimes windows can get over-specified in this area in an effort to use the sun rather than a furnace. However, this can cause massive overheating of your house during hot seasons. This goes back to my point earlier about the importance of helping customers understand different circumstances like building orientation or shading, and then planning accordingly. Just because someone's specifying a certain glass type, do you really know what that's going to be like? We don't want anyone calling us in a year, saying, "Why is it so hot in my house? My air conditioner can’t cool it."

So again, it comes down to education. I think we as a fenestration manufacturer have a responsibility to impart our knowledge, and to share as much as possible so people make educated decisions. All of the windows we're selling are designed to last for 25 or 30 years. If you don’t take building orientation or shading into account, you may need to reinvest in windows once again after only five years. It is important to think ahead to avoid that.

PHA: Well, I think that's a terrific place to end. Once again, thank you for taking the time to sit down and speak with us.

To learn more about EuroLine Windows, you can visit their site here.