Wildfires continue to make headline news year after year, and the stats and forecasts for coming years give us reason to believe there is no end in sight anytime soon.

It’s one of several reminders about the realities of climate change. Rising temperatures and droughts, particularly in dry regions, increase the risk of wildfire. And those regions are expanding into areas previously considered at low risk for wildfire. Compare a WUI zone map from a few years ago to one today and you’ll see.

The building materials industry has a role to play in addressing this and many other risks associated with climate change. The most obvious opportunity—and the one most frequently discussed these days—is improving the energy efficiency of building stock, primarily in dense urban centers. But when it comes to improving the fire resiliency of buildings, ROCKWOOL is uniquely qualified to tackle this challenge. More on that later.

Build Better in High-Risk Areas

Let’s start by addressing the irony that building continues at an accelerated rate in those WUI regions. In large part because it’s affordable. Ongoing population growth and urban sprawl are driving significant housing development into environments in which fire can move readily from forests and grasslands into neighborhoods. There are also many who move to these picturesque locales for the privacy, natural beauty, and the desire for active outdoor living.

It’s our job in the building materials industry to help educate builders and homeowners alike about options for building better in these regions. One such option is to refer to WUI zone building codes. California, for example, has codified WUI zone requirements for many construction features, including fire protection. Codes outline the basic requirements a home must meet, like the performance expectations for materials and assemblies that can be used, and the technical standards that must be met, like those that have been adopted into the code that have been published by ASTM and NFPA.

Here’s another thing about codes as it relates to fire: They are meant to slow the spread of fire in a building once it’s started. There is a lot more known today about how to slow the spread of fire from landscape materials and prevent fire from spreading to homes.

The bottom line: Codes set minimum requirements; building or rebuilding a home with the greatest possible fire resilience is voluntary.

Until that gap in code is resolved, we’ll continue to do our part to advocate for applying the best building science principles and using the products that provide the greatest fire resiliency. That often means focusing on the building envelope. Let’s break down what some of those wall and roof assemblies look like, and why they are the best choice for those building in high-risk areas.

Fire-Resilient Building Envelopes

Specifying fire-rated assemblies and fire-resistant materials for the building envelope is the best strategy for limiting the spread of fire. Best practices today demand more. Fire safety must be accounted for early in the design process. This is especially true for WUI zones, where a holistic approach needs to be applied. What does that look like?

We recommend architects and builders think differently about the house design—especially if they are rebuilding after a fire. How can you design a better building to provide a better chance of slowing a fire from penetrating the structure? It requires, in part, understanding how it is that homes catch fire.

Then it’s important to look at materials to determine whether they are combustible or non-combustible, whether they’re ignition-resistant or fire-resistant, and whether they have low or high flame-propagation rates. The next step is a challenging one: taking this information into account while designing fire-resistant assemblies.

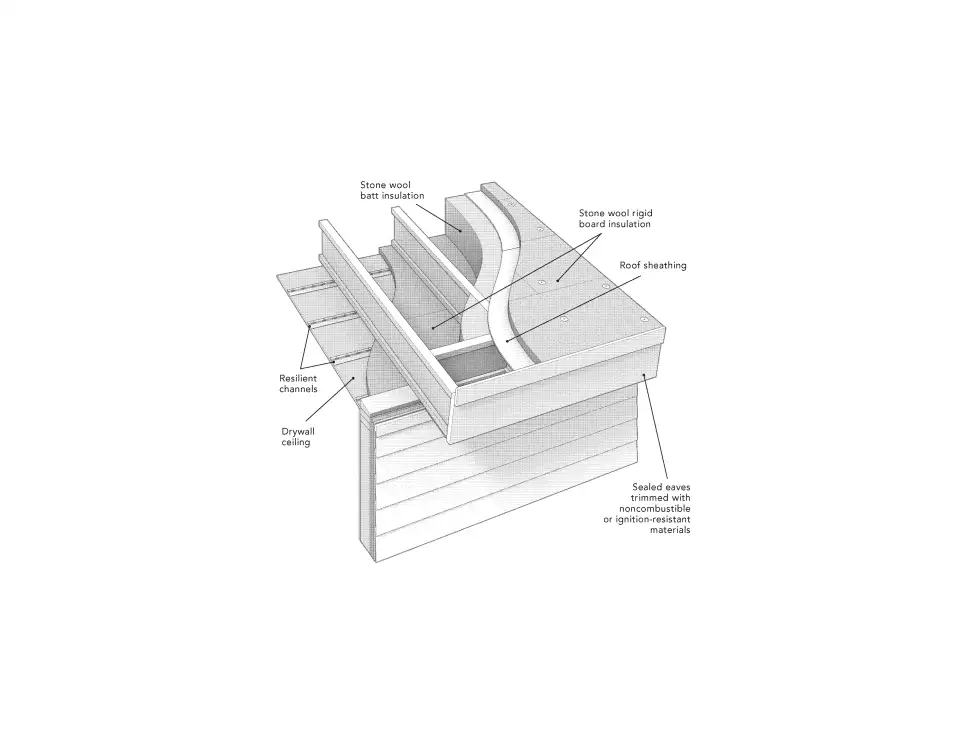

Roofs

A fire-resistant roof assembly includes not just the surface product, but also the underlayment, sheathing, insulation, joists, and other components that go into a roof. ASTM E108 Class A¬-rated surfaces like clay, concrete, slate, and many types of asphalt or metal are good selections, but builders also need to consider components beneath the surface material.

Non-combustible roof insulation boards, tested in accordance with ASTM E136, can improve the roof assembly’s fire resistance, for example. There are non-combustible options, including several stone wool insulation products. Builders should look for products with a flame-spread index of 0 and a smoke-developed index of 0 when tested in accordance with ASTM E84, which can improve a roof assembly’s ability to withstand conditions during a wildfire.

Other measures for creating a fire-resistant roof assembly include:

Eaves. They should be sealed, and valleys should be covered by an ASTM E108 Class A material to prevent embers from igniting the roof.

When gaps exist within a roof system, the space at the eave ends should be filled to prevent ember and flame entry.

Vents. These should be covered with 1/8-inch mesh to prevent embers from getting into the house.

It’s also important to use ignition-resistant or non-combustible materials like metal and fiber cement for the soffit and fascia to further protect the eaves.

Walls

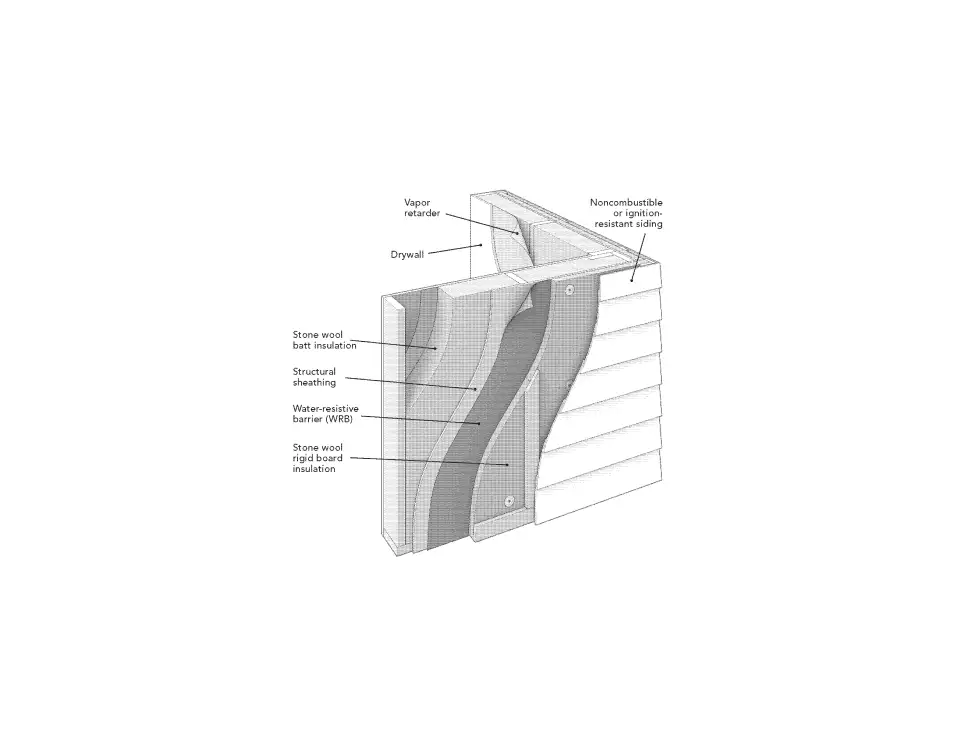

Similarly for wall design, fire-resistant cladding will only go so far; all components of the wall assembly need to be considered as the fire-rating of the assembly is determined by the combination of materials that make it up, tested in accordance with ASTM E119. Vinyl siding does not provide a lot of protection. It tends to melt and fall away from the structure. It is the materials behind the vinyl siding that can either make or break the system.

While non-combustible or ignition-resistant materials like fiber cement, stucco, plaster, brick, and stone are preferred siding, it is possible to comply with state level codes such as the California Building Code’s Chapter 7A, for example—which stipulates materials and construction methods for wildfire exposure—even when using a product like vinyl siding. This means complying with the State Fire Marshal Standard SFM 12-7A-1, now referenced in ASTM E2707, 2022 version, which tests the ability of the wall assembly to resist the penetration of flames into the stud cavity.

Insulation

Now let’s talk about insulation. This is something we happen to know a lot about. When it comes to the building envelope, stone wool insulation is an ideal material in these fire-safe assemblies. Why? It’s naturally non-combustible (tested in accordance with ASTM E136) and able to withstand temperatures up to 2,150°F (1,177°C). It limits the spread of fire, slows the transfer of heat across the wall assembly, and will not contribute to smoke development with added design flexibility for ASTM E2707 or NFPA 285 assemblies including unlimited insulation thickness to meet increasingly stringent thermal requirements. Foam plastics, in contrast, are limited to maximum thicknesses.

Selecting stone wool insulation is an ideal solution for the challenges of building a high-performance home in a WUI zone. It makes it possible to achieve aggressive goals for energy efficiency as well as fire resilience, and to reap additional benefits from the stone wool, including:

Vapor permeability. Stone wool is water-vapor open, allowing vapor to pass through the assembly for superior drying capabilities

Dimensional stability. Stone wool products are dimensionally stable over a wide temperature range, meaning they do not expand or contract with seasonal thermal cycles, providing consistent property performance over time

Chemically inert. Stone wool insulation products are chemically inert and non-corrosive, and are resistant to mold and fungi

Termite resistance. Stone wool has been tested and demonstrated to not contribute to termite development

We got technical there, but we can’t talk about it enough. The design and application of those assemblies are what will truly make a difference for homes built in fire-prone areas.

Walking the Talk on Sustainability

Here’s the thing about ROCKWOOL. Advocating for architects and builders to specify stone wool for greater fire resilience is consistent with the organization’s sustainability policy from the very top. Our goal is to make a positive impact on people and society through the products we make and how we operate as a business. We transform volcanic rock into stone wool and those insulation products contribute to addressing many of society’s biggest climate change challenges, creating new opportunities to enrich modern living and build safer, healthier and more climate-resilient communities.

Learn more about ROCKWOOL here.