Whether you’re building or renovating a home, it can quickly become a big investment. It would make sense that you would want to protect this investment and ensure its durability as well as the health of the people living in your home. If you’re someone who’s fallen in love with natural properties of cork but are unsure whether you can use it to insulate your home, then this blog post is for you!

Cork has been used for hundreds of years as an insulation material and ThermaCork is composed of 100% cork, is carbon-negative and has no chemicals added in production. Builders and homeowners who are considering cork may worry whether using cork as insulation puts them at risk for developing mold. The simple answer is no, if the wall assembly is done correctly. More details about mold, mold prevention and correct wall assembly are outlined in this blog post.

Mold and Mold Prevention in Building Assemblies

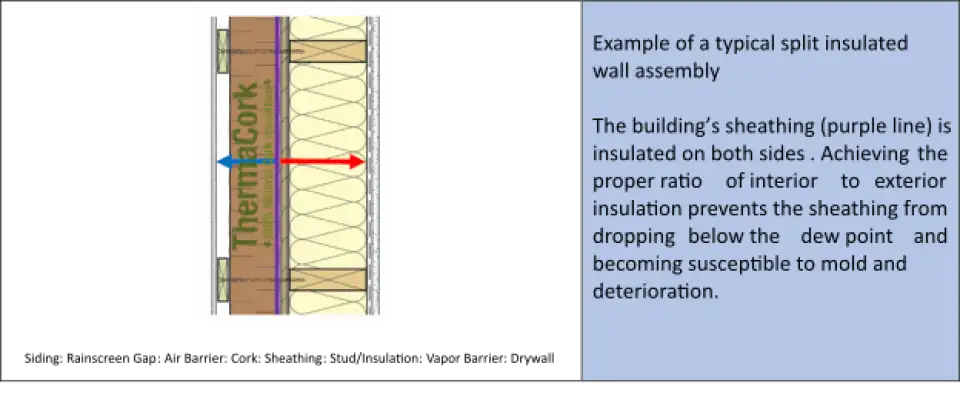

Mold can damage your exterior sheathing by accelerating decay and can become harmful to your health if allowed to get out of control. Mold can form on exterior sheathing and wood framing when water vapor in the building assembly is not properly managed. Depending on where you live, the strategies for vapor management can differ. Here on the west coast of the US, split-insulated walls are becoming popular and these can help by keeping the sensitive materials like wood framing and sheathing sufficiently warm to prevent extended periods of high relative humidity.

A well-designed building assembly ensures both airtight design and protection from mold and deterioration

Typically, in winter when you are heating your home, the batt insulation in your stud cavities lowers the exterior sheathing’s temperature. Lower temperature surfaces are a collection point for water vapor to turn into condensation, a leading factor of mold and deterioration. To prevent this, it is important to get the ratio of interior insulation and exterior insulation correct so the exterior insulation can keep sheathing warm and safe from condensation.

In order to determine the optimum amount of cork needed for west coast climate zones, ThermaCork commissioned Vancouver, BC-based RDH Building Science to do a study. RDH is one of North America’s leading independent building science resources with 9 offices across the continent. A report with new data sets for cork insulation was developed in RDH’s lab in Waterloo, Ontario office, with additional review provided by the three RDH offices located within the study climates (Vancouver BC, Seattle WA and Oakland CA). The takeaway of the study is your guide to designing a cork wall assembly that will ensure that your walls stay healthy and meet the demands of your climate zone.

Three Values You Need When Designing Your Wall Assembly

1. Your Climate Zone

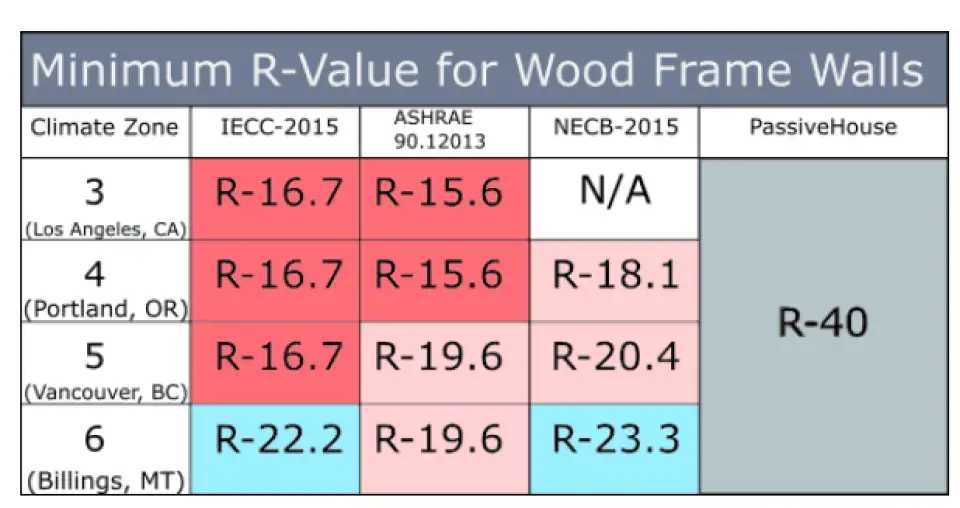

When starting to design your building, it is important to follow any building and energy efficiency requirements and standards. There are many regional codes, but the insulation and vapor control requirements generally fall around some common values. You can easily find these if you know your climate zone. The specifics of these codes are dependent on your area, and beyond the scope of this article, but you should certainly investigate which sets pertain to you.

To represent the most common west coast climate zone scenarios, the study took in to account the following codes using prescriptive requirements:

IECC International Energy Conservation Code ‑2018 §R402

ASHRAE American Society of Heating, Refrigeration and Air-Conditioning 90.1–2016 §5.5 Wood-Frame

NECB National Energy Code of Canada for Buildings-2015 §3.2.2.2

Passive House: assumed target of R‑40.

Which of these applies to you depends on your climate zone, local codes, and energy conservation target.

2. Your Required R Value

Once you know your climate zone, finding the remaining factors will be much easier. To determine how much cork you would need as exterior sheathing, you need to know your required R Value. R value is the standard metric for determining insulation performance. The higher the value, the better at insulating the material is. In a typical building situation, the amount of batt insulation (what goes between the studs in the wall) is governed by the depth of the stud; in west coast climates, 2x4 walls are generally insulated with R‑13 batt, and 2x6 constructions are around R‑21. Knowing this value is the cornerstone of establishing your ratio of interior to exterior insulation.

3. Your Vapor Control Strategy

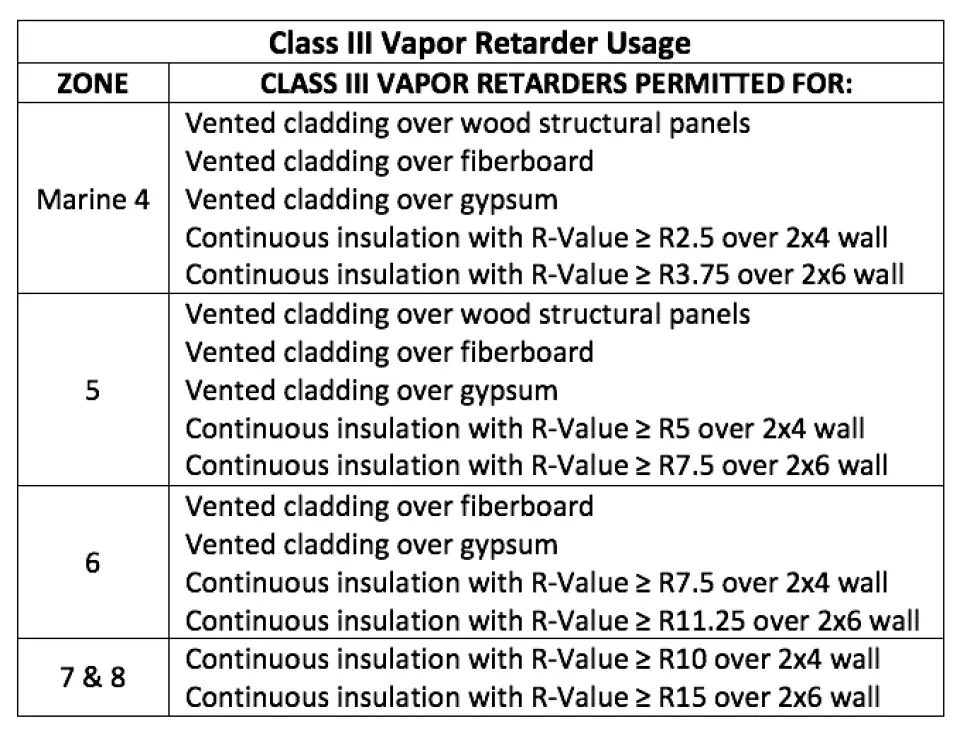

The last variable to the equation is vapor control, or the flow of moisture across an enclosure. Vapor retarders of differing classes exist to mitigate the exchange of vapor between the interior and exterior through a home’s walls, allowing you to keep water out while still allowing it to escape if it does get in. Vapor retarders are classed by their perm rating. A perm is a measurement of water vapor transmission. A Class III vapor retarder allows the most vapor transmission (greater than 1 but less than 10 perms), while a Class I barrier allows little to no transmission (less than .1 perm), with Class II falling in between (greater than .1 but less than 1 perm).

A vapor retarder can be as simple as asphalt coated Kraft paper (Class III – Class II), all the way to less permeable materials like .6 mil polyethylene film or foil faced insulated sheathing (Class I). One thing accounted for in the study is that cork insulation retards vapor flow more as the thickness increases, which can potentially inhibit outward drying, so a balance has been found between the insulation ratio and drying capacity of the wall assembly.

Local Vapor Control Codes Vary

In many places, strict vapor control policies exist, while others allow vapor permeable assemblies. The International Residential Code details some permissible solutions, i.e. a class I or II vapor retarder is required on the interior in climate zones 5, 6, 7, 8 and Marine 4. Class I vapor retarders may not be used on the interior of Climate Zone 3 and 4, other than Marine 4. However, a Class III vapor retarder may be used provided that the requirements in the adjacent table are met, and this seems to be the route typically taken, though there are better solutions. To represent the worst case scenario, the results of the test assume the use of Class III vapor control falling under the use of the previous table. Performance can be greatly increased by using better vapor control where permissible. Wall assemblies tested also included a rainscreen/back-ventilated cladding design.

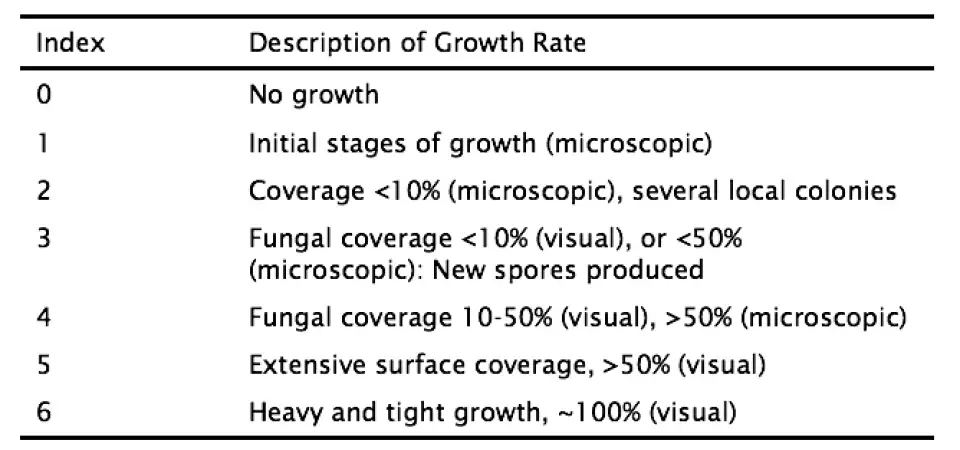

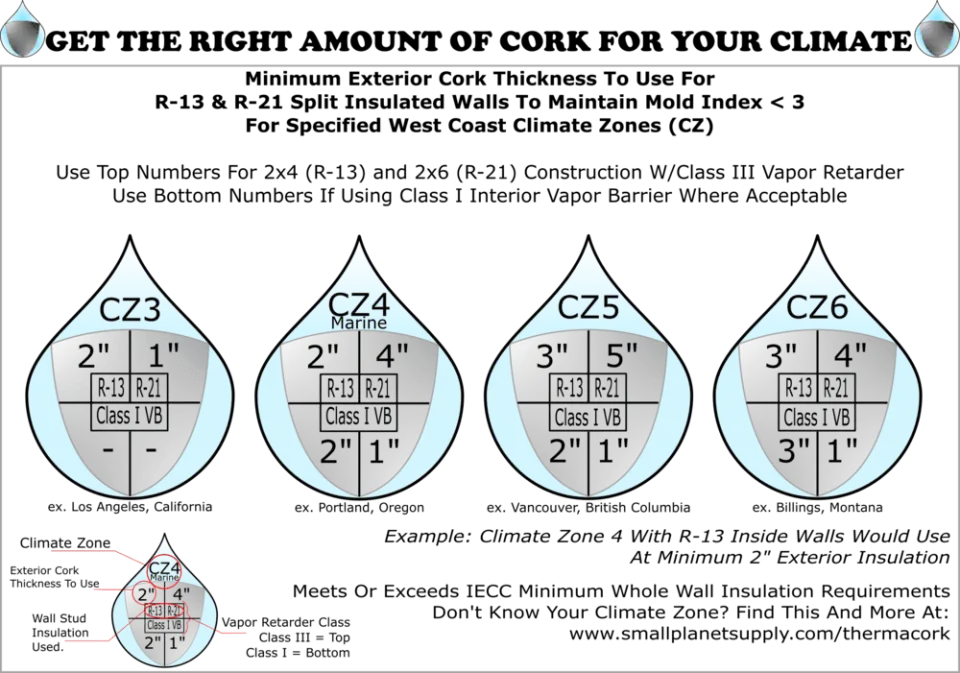

Planning and Building the Correct Wall Assembly Reduces Your Risk Of Mold

All these building requirements factor together to achieve an energy efficient and durable assembly. When properly followed, the structural framing and sheathing of the building are less likely to develop condensation and mold damage. The American Society of Heating, Refrigeration and Air-Conditioning uses the VTT Mold Index to predict the risk for mold growth. The index is applied on a scale of 0 through 6 and is now being applied as improved moisture performance criteria. As such, the results of the test have been consolidated for ease of understanding and are put up against the Mold Index (M). ASHRAE 160‑2016 recommends a mold index of 3 or less as the safe threshold of performance. The graphic below (Get the Right Amount of Cork for Your Climate) gives the minimum thicknesses of cork for each climate zone and interior insulation value to achieve M < 3 for typical 2x4 and 2x6 constructions using Class III Vapor Retarder, except where noted, the bottom row includes the use of a class I vapor barrier.

Special Circumstances

You can download a PDF of this graphic by clicking here.

Finally, do realize that if you are building to Passive House standards, your exterior insulation thickness will far exceed these numbers. This will still excel at keeping your sheathing warm and out of danger of condensation. Additionally, if you maintain an interior relative humidity below 50% throughout the winter, i.e. with the use of a dehumidifier or HRV system, you can greatly improve the performance on any of these assemblies. Please note that these figures are guidelines based on RDH’s test output; designers should always ensure wall assemblies conform to local codes. A copy of the RDH report is available by clicking here.

Since we can’t easily look inside our walls, studies like this are invaluable when constructing buildings to last.

A Little Knowledge and Planning Puts Your Mind At Rest and Lets You Love Your Cork

With advance planning and a properly designed wall assembly, you can enjoy the 100% natural option of expanded cork insulation for many years to come.