Domestic Hot Water metering is a powerful tool when right sizing heat pump plant for retrofit projects

This will result in reduced project capital costs and improved business case

Retrofit projects offer an excellent method of validating equipment sizing methodologies, by using “real-world” consumption data

Domestic Hot Water (DHW) Electrification

Domestic Hot water heating is a significant building energy consumer, often second only to space heating. Depending on the number and type of building occupants, hot water consumption may account for more than 20 per cent of total annual energy consumption.

As the City of Vancouver, and Province of BC set aggressive carbon reduction targets for buildings, domestic hot water electrification has been identified as a key strategy in achieving these targets.

The Challenge

Given the higher sensitivity of power requirements, space availability and capital cost in DHW electrification retrofit projects, it is imperative that equipment is right sized to achieve the optimal balance between peak consumption and water storage capacity.

There are several methods of deriving domestic hot water system sizing, with ASHRAE, ASPE and LEED all using different methodologies.

Opportunity

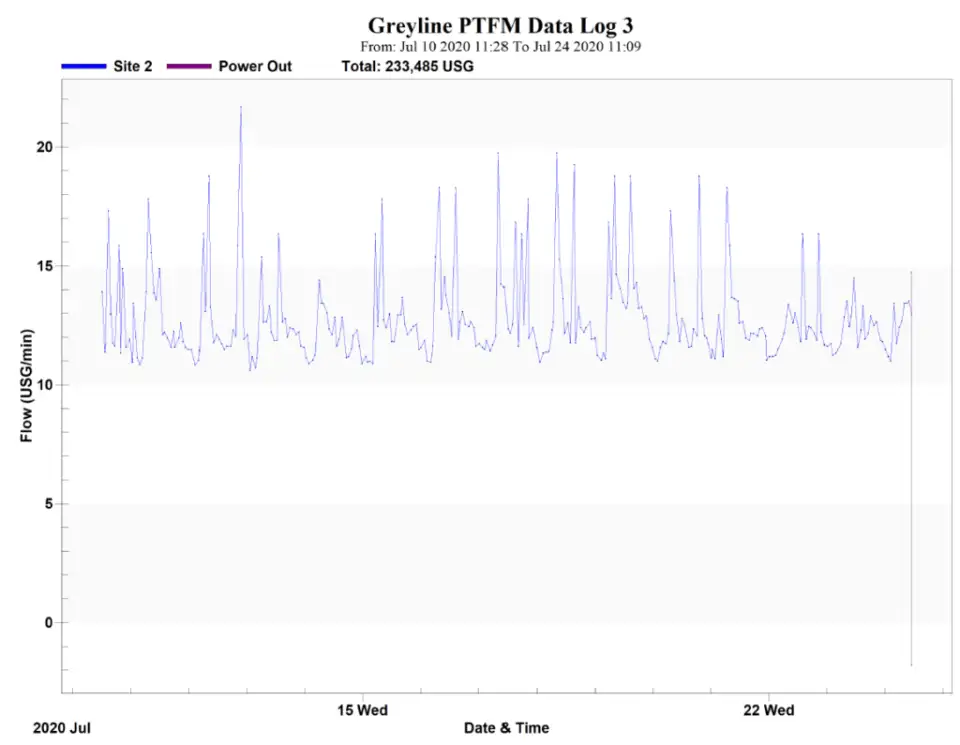

To better inform heat pump equipment sizing for retrofit projects, DHW metering can provide actual “real world” consumption data to support the design. Retrofit projects offer a unique opportunity to study how occupant user patterns drive DHW consumption.

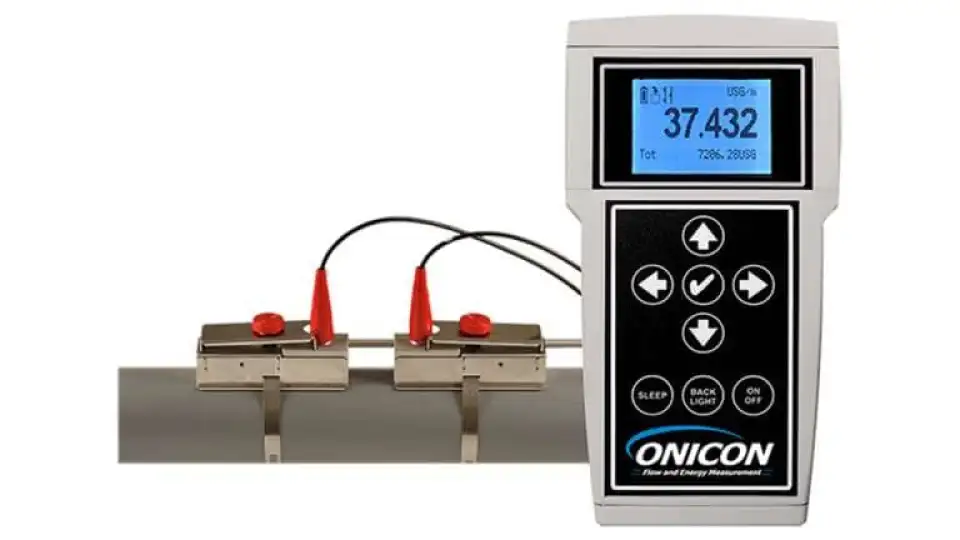

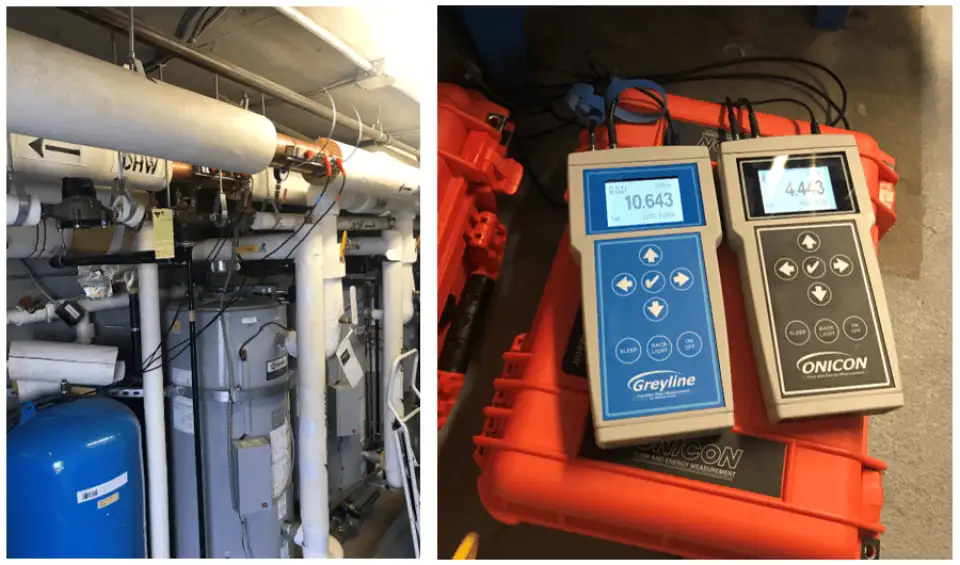

Impact Engineering utilize ultrasonic flow meters on our projects to measure domestic hot water consumption and build profiles to better inform our design.

The Measurement Process

Ultrasonic flow meter sensors are clamped directly to domestic hot water supply lines, and flow rates are measured in gallons per minute, stored on the main terminal device.

The meters are typically installed for a two-week monitoring period to get a comprehensive data set.

Key Findings

Some of the key findings from our recent work includes;

Recirculation accounts for most DHW flow (up to 90% in some cases)

Legacy DHW heating plant is often oversized, especially if the building function has changed over time

Peak flow data is useful in guiding discussions around equipment redundancy

Opportunities

If you would like to learn more about the benefits of DHW metering for your facility, please reach out.