The right tools can make such a difference. Lucie Langlois, principal of Alias Architecture in Quebec, is finding that SketchUp and DesignPH are helping to streamline the design process for her second certified single-family Passive House. Because she can see immediately the impact of her choices on the home’s efficiency, she can more quickly find the solutions she needs. Working with an experienced builder, the greater availability of Passive House-quality products, and the PHI’s reconfigured primary energy renewable (PER) factors are also advantages.

Langlois designed the first certified Passive House in Quebec in 2014—a project with many challenges, starting with the relatively small volume of that single-family house and the tough wintertime climate. That experience was invaluable, giving her a practiced understanding of creating a Passive House in her climate, where wintertime temperatures average –9°C.

One takeaway from that project was that the two-story house she had originally planned did not result in sufficient volume to allow for meeting the heating requirement; only the addition of a basement, which enlarged the treated floor area and improved the volume-surface area ratio, made hitting the target feasible. The family who live in the home have made great use of the added space, turning it into a generous play and workshop area.

Other hurdles included the primary energy penalty the PHI then gave to all electricity used in a building, regardless of how the electricity had been generated. All that has changed. The PHI’s PER factors recognize hydropower—the source for Quebec’s electricity—as a renewable energy, making it more practical for an all-electric house in Quebec to meet the primary energy performance target.

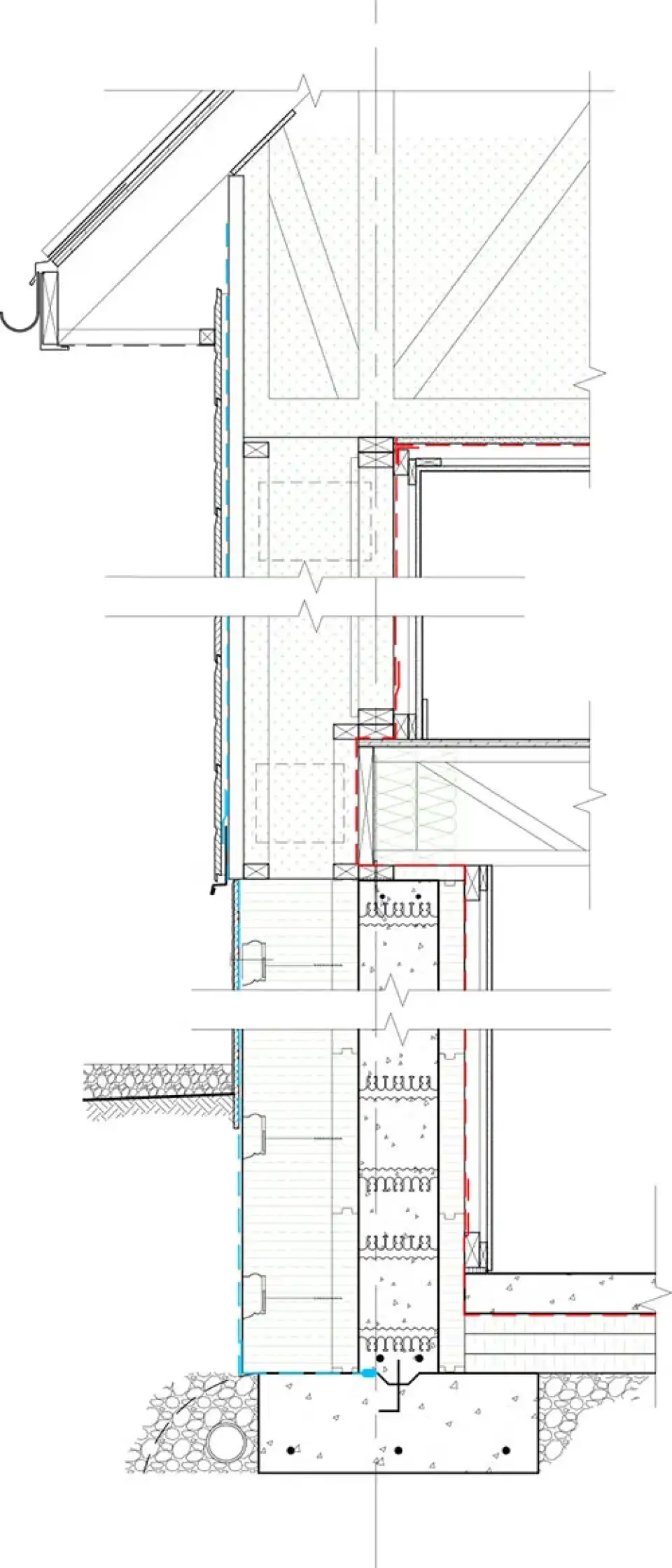

Langlois’s current project, a 222-m2 house in Dorval, a suburb of Montréal, has two floors plus a basement, designed in from the start. The basement, says Langlois, is a good solution in their climate, because it cost-effectively produces useful space and also elevates the ground floor above the snow level. The foundation walls have to be set deep enough to avoid freezing the footings, so extending their height enough to create a full basement is not a large cost premium. For this house the basement walls are using an ICF system with an additional 9 inches of exterior polystyrene. The kitchen and great room occupy the ground floor, with three bedrooms and a bath on the second floor.

The whole structure hugs the north end of the lot in order to give the south-facing façade greater exposure to wintertime sun. The front of the house faces east, while an attached garage buffers the house on its northern end. On the western façade, a large sliding door in the dining room affords access to the backyard. A 3-foot overhang shades this door, along with deciduous trees. The overhang continues around to the southern façade to screen the windows there. It also breaks up the fairly uniform building shape.

In order to use DesignPH, Langlois had to learn SketchUp, which was very simple and akin to drawing by hand, she says. The preliminary drawings were easily imported into DesignPH, allowing her to check to see if she could reasonably hit her Passive House performance goals. For Langlois, the one big drawback of DesignPH is that it doesn’t adequately simulate the risk of overheating. Potential fixes to any overheating problems, such as window size and shading, can have large consequences for the home’s overall design. However, the newest iteration of DesignPH will address this issue. Her ultimate PHPP model was finalized with the help of Maxime Thillaye Du Boullay, a French engineer and Passive House consultant.

While working out the construction details, Langlois had the advantage of collaborating from an early stage with Richard Price, the builder who constructed her first certified Passive House. They are both familiar with the challenges ahead and conversant with the potential solutions, simplifying the entire process. The exterior walls will be a double-wall construction with 14-inch trusses filled with cellulose wrapping the home. The clients opted for aluminum cladding for its easy maintenance.

The mechanical system choices have improved substantially since Langlois’s first go-around. Heating, cooling, and ventilation are being provided by a relatively new, locally produced conditioning ERV. Heat pump water heater options have become more readily available, and that combined with their relatively high coefficient of performance has made this type of water heater an obvious choice, as its contribution to the total primary energy use is small.

The vent hood in the kitchen, required by local building codes, is another hurdle that Langlois and Price have addressed before, so it’s one more problem that isn’t. This nexus of better software, more product choices, and previous experience is a sweet spot for Passive House building in Quebec.

|

Heating energy |

4.2 kBtu/ft²/yr |

11.2 kWh/ft²/yr |

13.2 kWh/m²a |

|

Cooling energy |

0.6 |

0.2 |

2.0 |

|

Total source energy |

18.5 |

5.4 |

58.4 |

|

Peak heating load |

13.8 Btu/hr/ft² |

11.1 Watts/ft² |

12.0 Watts/m² |

|

Peak cooling load |

2.5 |

0.8 |

8.6 |

|

Air leakage |

0.6 CFM50 (design) |