New housing in the United Kingdom (UK) has earned an arguably well-deserved reputation for being of poor quality and unimaginative design. According to the Bartlett Review, a highly regarded report into UK housing, 51% of new homeowners in the UK experience major problems with their properties! The team at Kiss House—an innovative Passivhaus housing specialist that delivers off-site manufactured housing using modern methods of construction—has dedicated the last 20 years to bucking this trend by constructing exemplary Passivhaus and very low energy homes. Indeed, the UK firm offers Passivhaus-certified houses as standard, and many of their homes have won awards.

A couple of years ago, however, the Kiss House team became disillusioned with delivering bespoke or custom housing, knowing that each project was a one-off and effectively a prototype with no clear mechanism for taking the lessons learnt, and problems solved, forward to the next project. The team became determined to create a repeatable housing product with customizable elements that marry great design and high performance with a hassle-free delivery model. “Creating homes that are a joy to live in is a primary motivation for us, so the Passivhaus standard had to be central to our offer—it is after all the comfort standard,” says Mike Jacob, Kiss House founder and director. Jacob continues, “An exciting consequence of us developing a Passivhaus housing product has been that it has led us into innovation, and we have now innovated low-carbon building materials and systems that have mass market potential.”

When the Covid-19 pandemic hit early in 2020, the housing projects that Kiss House were working on were delayed, so the team responded by putting a greater focus on R&D initiatives. Fast forward two years to March 2022 when the results of this work were unveiled at the Futurebuild Exhibition in London: the Kiss House construction system for low-rise homes. Rob Ewen, executive director of The Line—NEOM described it on LinkedIn as “Beautiful, efficient, effective, sustainable, simple—a building system designed for the future, deliverable today.” Now, Kiss House is poised to deliver on its first two homes using the company’s housing product system in Reading, a large town 40 miles from London.

The Total Package

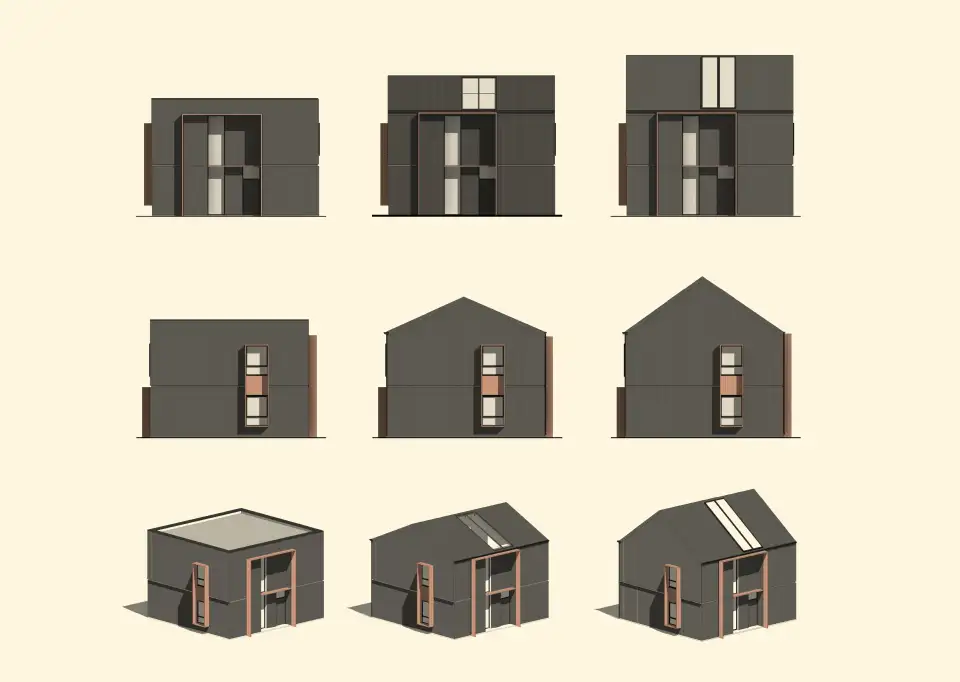

The Kiss House low-rise residential construction system is a timber component-based system, with each element of the system best thought of as a collection of structural rules that result in components with variable dimensional values. Some dimensions are fixed while others can flex to achieve different building designs. Precision manufactured off-site and then assembled quickly on-site, the system streamlines the delivery of high-performance, low-carbon dwellings that are designed to achieve the Passivhaus standard. The component-based system was originally conceived to deliver the Kiss House housing product; however, it is now being offered more widely and is available as a system to other house providers.

The thoroughness of the Kiss House system goes beyond the traditional prefabricated housing’s product of four walls and a roof. “We didn’t want to stop there, because the thought of digging a hole in the ground and then filling it with concrete and steel or putting petrochemical-based insulation in the walls wasn’t a good one. We wanted to create a ground-floor system that was as smart as the houses we’d designed and to use natural renewable materials wherever possible,” says Jacob. “This began two years of intense product development and testing including work with Bangor University and design for manufacturing and digital design specialist Bryden Wood amongst others.”

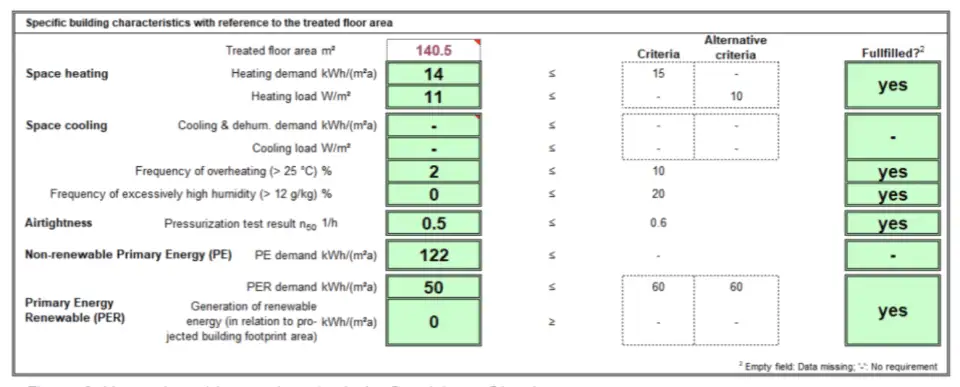

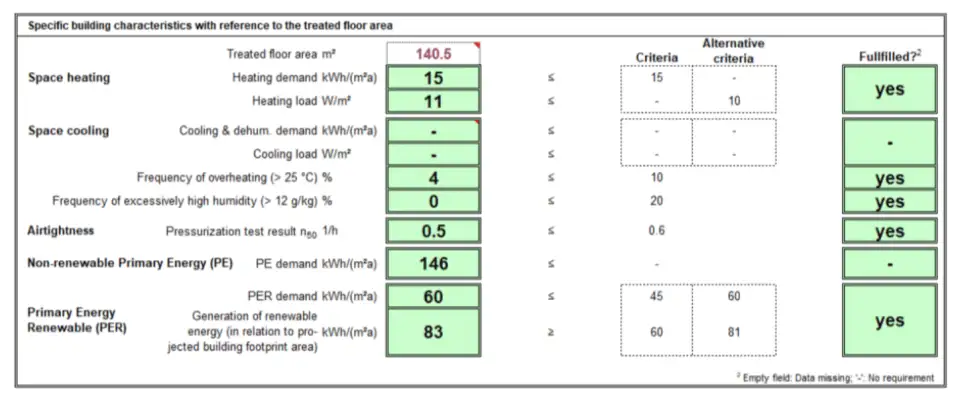

Kiss House now has two patents pending: one for a Passivhaus-compliant ground-floor system that virtually eliminates concrete and steel, and the other for an enhanced natural fiber insulation product that enables the Kiss House system to use a standardized wall build and still achieve the Passivhaus standard across most sites. “Kiss House now has four housing projects in the late stages of planning where we are showcasing these innovations. The rationale when developing our system was to base the model on a real project, which is Gloucester Road. It is soon to be the first Passivhaus development in our hometown and, interestingly, is why we just won most sustainable stand award at the Futurebuild Exhibition in London. Instead of building an exhibition stand that would not be reused, we exhibited three sections of one of the houses,” said Jacob. The Kiss House system has been designed in accordance with the Passivhaus standard and follows the requirements for Passivhaus components, but its system components are not certified. However, the team has initiated the process for certifying its components with the Passivhaus Institute.

Gloucester Road

The first two Kiss House housing product homes have been designed for a family that is local to Reading and wishes to build highly sustainable family homes that work sensitively within the local area. Each roughly 150-m2 (1,600 ft2) home will have four bedrooms. The homes are being constructed on a 0.3-hectare infill site with access by foot to all established local amenities, including shops, schools, hospitals, and all modes of public transport. There is an existing building on the site, which, while not listed, is of historical significance locally as a former Quaker Meeting House, dating to approximately 1880. Retaining this beautiful old building has been an important element of the project. Homes in the surrounding area are predominantly Victorian red brick with some buff brick and render.

This project is currently in the final stages of the UK planning system, having taken two years to get approved due to Covid-19. UK planning laws tend to be very strict regarding proximity to other buildings and protecting privacy, requiring extra attention in this infill site to ensure that privacy is maximized and minimum distances are not exceeded. In addition, the site is flanked by steep banks on two sides, which also impact the positioning of the two dwellings. In further complications, the site is accessed by a narrow residential street that will require careful planning in relation to craning and lifting onto site. These difficulties are mitigated by the Kiss House model that enables efficient site erection of the dwellings.

The Kiss House aesthetic is simple, crisp, and modern, with clean lines and meaningful repetitive openings. Ceiling heights are generous, and consideration is given to light, space, and flow through the building. The material palette is partly governed by the system but is also sympathetic to the local area. The team undertook a color study of local materials to ensure that the palette chosen would be modern and yet relate to the more traditional materials used locally in hue and tone. The result marries Western Red Cedar cladding with Corten steel accents that blend with the local red brick.

Kiss House undertook the design and planning of this project, with additional engineering by Bryden Wood. As this project was being developed alongside the design of the Kiss House system, prototyping has been ongoing, which has been undertaken by manufacturing innovation specialist Easi-Space. Given the kit of parts approach, the team estimates that completing each house will take 4-6 weeks once on-site assembly begins. The team is looking forward to starting that stage soon.

For more on Kiss House, visit www.kisshouse.co.uk.