By Jay Fox

New York University has long sought to be a leading voice in sustainability. Since their first pledge to reduce emissions was issued in 2006, the university has taken decisive action and plans to be carbon neutral by 2040, according to NYU Chief Sustainability Officer Cecil Scheib. As NYU is the largest private university in the United States—with more than 15,000,000 square feet of leased or owned space to accommodate its approximately 50,000 students and 20,000 employees—this will inevitably mean performing deep energy retrofits on the older buildings in the university’s portfolio.

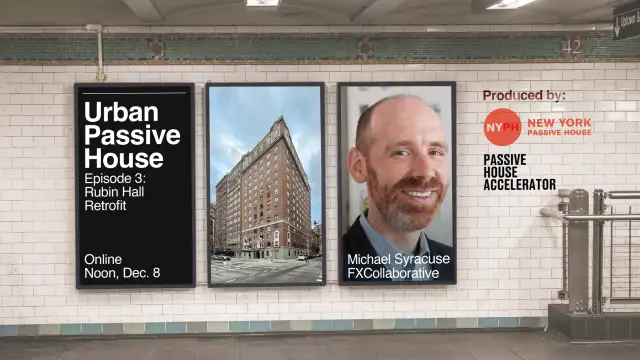

Scheib notes that the university is considering high-performance and all-electric options in every retrofit, and that they are committed to obtaining LEED certification (Silver minimum) for every project involving a substantial renovation or new construction. However, they have also explored more aggressive strategies when refurbishing some buildings, as was the case with the retrofit of Rubin Hall, a student residence near the university’s core campus in Greenwich Village.