The Making Cents of Carbon design by Alison Nash, sustainability practice leader at DiMella Shaffer, with consultant James Costanzo of RW Sullivan won in the “Bring Your Own Building” category of MassCEC’s Triple Decker Design Challenge. Their design aims to demonstrate the feasibility, cost effectiveness, and common sense of a “carbon drawdown” building by utilizing mass-produced technology and market-ready construction approaches.

Their design is both replicable and scalable, because it uses products and construction techniques that are currently available in the Boston area. Further, their design approach considers a specific existing triple decker. The construction cost of the Making Cents of Carbon design is $326,408—not including the $42,000 PV array, which would bring the total cost to $368,408.

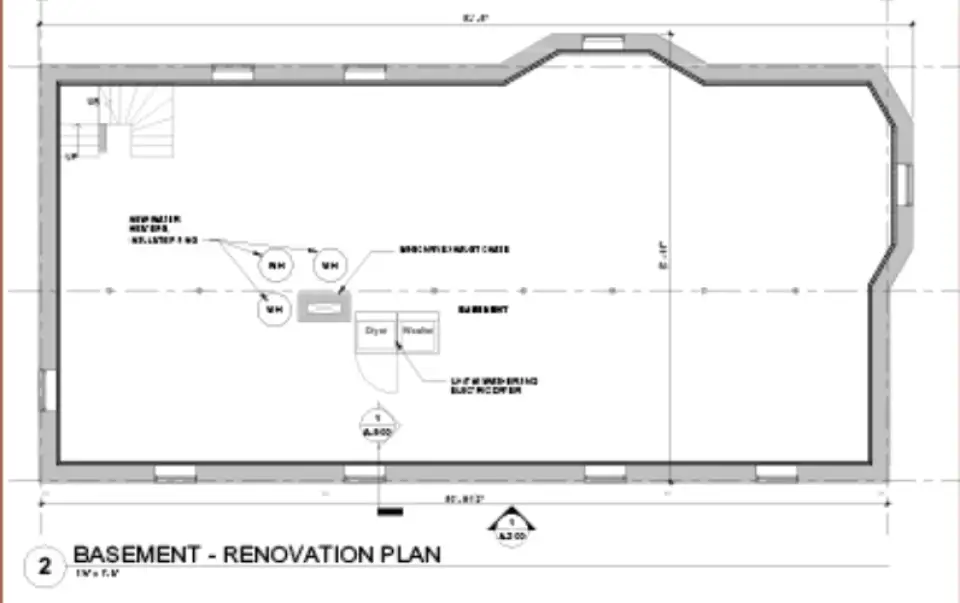

The retrofit approach of Making Cents of Carbon is influenced largely by Passive House principles, according to their Project Vision & Design Narrative, prioritizing envelope upgrades to reduce thermal loads and appropriately sized mechanical equipment. The design combines aesthetics with resiliency. By replacing the exterior siding and windows and installing a new sheathing layer with continuous insulation, the building will not only look attractive to the neighborhood but will also have greater resiliency to precipitation and winter storms. Further, the design moves equipment previously located in the basement to the tenant floors and the roof to account for adverse weather events—predicted for this site in Cambridge’s Climate Change Vulnerability Assessment—that could lead to occasional flooding in the streets surrounding the building.

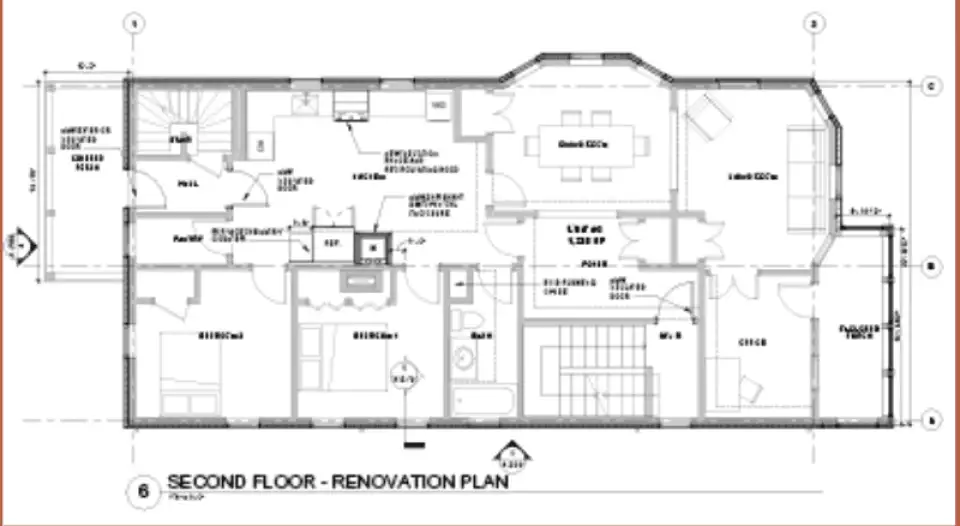

The roof of their selected building is close to the end of its life, so the DiMella Shaffer team included the installation of new cavity insulation, additional continuous roof insulation, and a new membrane roof. Heating, ventilation, and air conditioning will be supplied by roof-mounted units. The indoor unit of the new heat pump will be in a vertical chase closet located in the kitchen, with the new ductwork hidden in new soffits. The current electrical service to the building and existing electrical panels are undersized for the new electrical heating, cooling, cooking, and domestic hot water loads of the building, so Making Cents of Carbon also includes substantial electrical upgrades.

Graphic courtesy of DiMella Shaffer