While conceptualizing early design ideas for a multifamily building in the Roxbury neighborhood of Boston, Monte French, principal of Monte French Design Studio (MFDS), and Alex Yoon, project manager, were searching for an elegant solution to the question of how to fit seven stories of aesthetically pleasing residential units into a structure that is less than 70 feet. At 70 feet the building would become subject to Boston’s more cost-prohibitive requirements that apply to high-rise construction. That conundrum prompted the team to consider the advantages of a mass timber structure.

“Designing with mass timber was new to the team and new to Boston,” says Yoon. Still, as French notes, “It is so exciting to step outside the norm. We love taking on these challenges.” And, evidently, the firm loves compounding challenges, as this 34-unit building is both the firm’s first mass timber and first certified Passive House project. Michael Hindle, principal of Passive to Positive, has been the Phius consultant. Currently under construction, the building is slated for occupancy in fall 2022.

Back in 2019 as Yoon was puzzling over his options, he realized that there were only two construction approaches to achieve the unit density the client wanted and still keep the building under 70 feet—all concrete or mass timber—but the concrete structure did not meet the client’s and team’s shared sustainability goals. So, Yoon initiated a feasibility study of relying on mass timber for this seven-story structure, working closely with the firm’s longtime structural engineer. Yoon also visited mass timber projects that were under construction in New York and consulted with Woodworks and the Quebec Wood Export Bureau, resources for wood building design and construction. His research eventually led to Nordic Structures, where discussions about the process, schedule, and pricing convinced Yoon and French that this company’s prefabricated components would be a good fit for this project. At that time the use of heavy timber for a structure was limited to five stories, so MFDS applied for and received a variance from the state on the number of stories and concealed spaces.

The mass timber elements include 5-ply cross-laminated timber (CLT) floors, glulam columns, and a double glulam beam system. The beam system has both structural and mechanical, electrical, and plumbing (MEP) benefits. The system’s strength helps make feasible long, clear spans and generally thinner floor assemblies, while also providing a 6-inch gap at gridlines, allowing for vertical MEP stacks to run along the gridlines. All columns, beams, and 80% of the CLT slabs from below are exposed so residents can enjoy the wood’s natural warmth.

The roof structure also uses a 5-ply CLT slab topped with an average 12 inches of insulation, mostly reclaimed polyiso. A tapered layer of new insulation was used to create a slope for drainage.

Although the majority of the structure is mass timber, there are prefabricated concrete cores housing the elevator and stairs. These concrete cores obviated the need for additional shear walls or bracing. The parking garage at grade similarly relies on seven steel posts for structural transfer and clearance height to keep the structure under 70 feet.

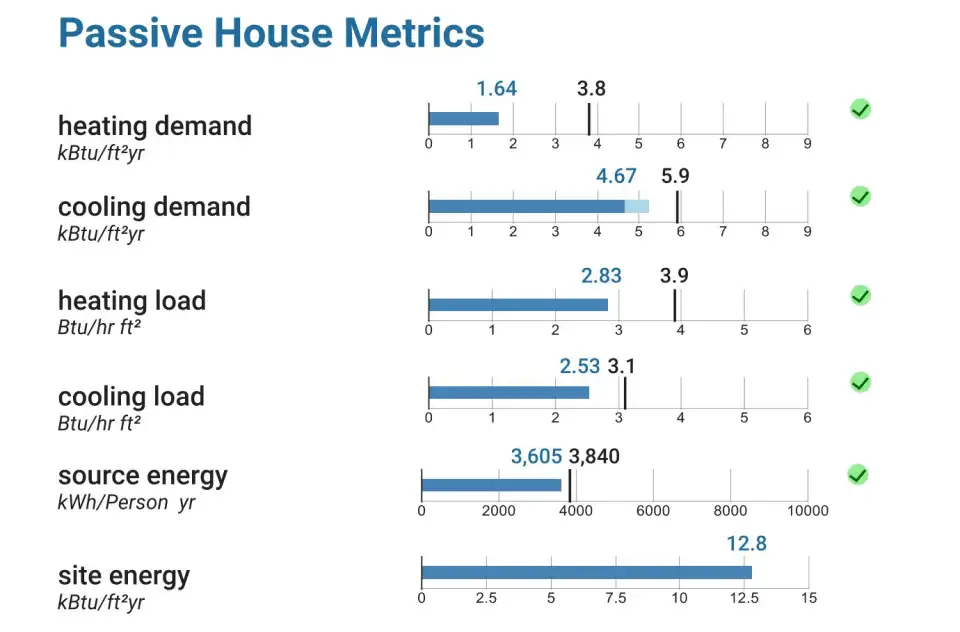

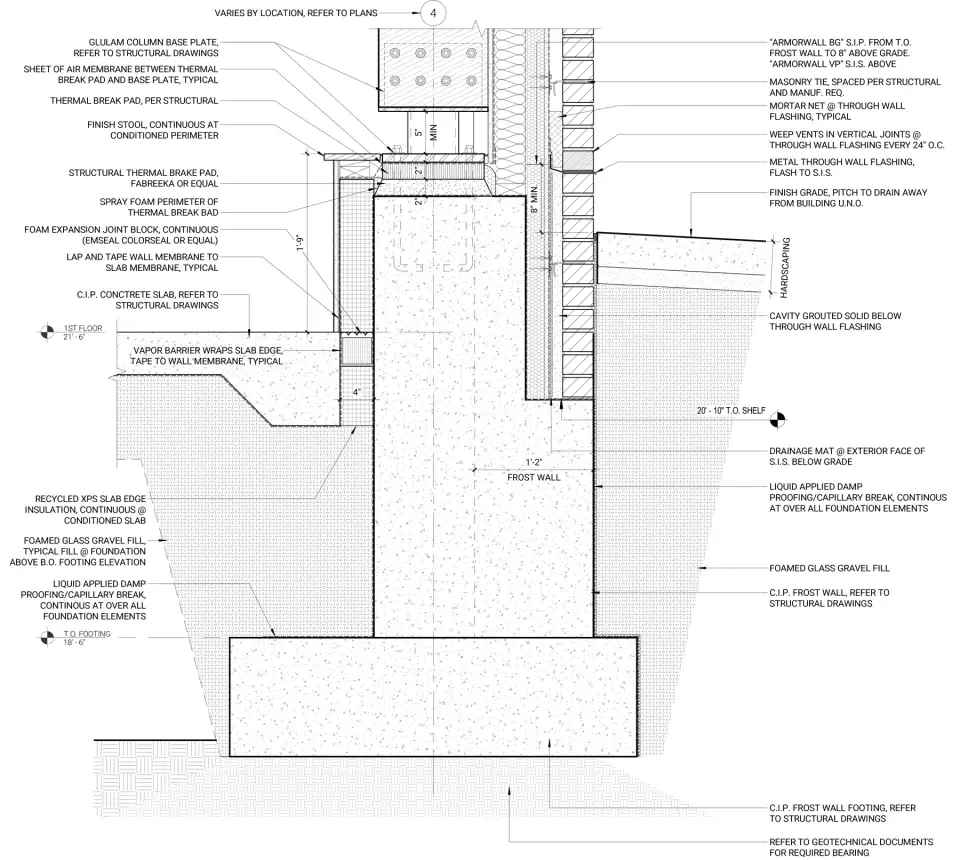

“Going to certification is a big commitment but not a big stretch,” says Yoon, discussing the firm’s decision to set Phius targets for the building’s performance goals. While this building is the firm’s first officially passive one, the team has used many Passive House strategies in previous projects, including highly insulated envelope assemblies, ERVs, thermally broken balconies, triple-pane windows, and heat pump systems. Yet, as with any passive project, especially one of this size, there are always new details to work out, including how best to interrupt the heat transfer from the glulam columns to the foundation. Finding the appropriate product—basically a 2-inch thermal-break pad that sits between seven stories of columns and the concrete piers—took research that led him eventually to three suppliers of pads that met his specs.

The exterior walls only required slight modifications from the firm’s typical stick-built assemblies, relying on a 2x6 stud wall filled with fiberglass batt insulation and a continuous exterior 2 ¾-inch structural insulated panel that is rated for commercial use and fire resistance. The cladding features a combination of fiber-cement and terra cotta paneling, and the triple-pane windows and patio doors both come from the same European manufacturer. In this market-rate rental housing, 24 of the 34 units include balconies.

“It was a major challenge coordinating the MEP with the mass timber structure,” notes Yoon, adding, “The floor-to-ceiling height to the exposed mass timber ceiling is 8 ft 8 inches, with no plenum space above it. A centralized fresh air system would have required large trunk lines from roof to grade and large plenums, which would have been close to impossible to do given these floor-to-floor heights.” Fortunately, with today’s emphasis on fresh air, a fully decentralized ventilation system has great market appeal, so the team chose to install individual Panasonic ERVs in each unit. Space conditioning is being provided by a centralized Daikin VRF heat pump system. An efficient semi-decentralized hot water system supplied by heat pump water heaters features two storage tanks on each floor serving five to six units, with optimized runs to each fixture.

French traces the success of this project to how committed everyone was from the beginning. “We are a small team, and the client is a relatively small developer. You need a good team in place that is mutually on board, because issues come up that have to be tackled quickly and fluidly,” he says. Yoon took the Passive House consultant course in 2020, and the contractor’s project manager underwent the Passive House builder training shortly after, helped out by state incentives that covered half the cost. With the team all pulling together toward the same goal, the building is on schedule to welcome its residents to their comfortable, beautiful apartments in the fall.