Carl Elefante, the past president of the American Institute of Architects, said that “The greenest building is…one that is already built.” Phius believes he is right in many aspects. Buildings in the United States were responsible for 27.6% of the total energy consumed in 2023 and 36.9% of the source energy, totaling 34.5 quadrillion Btus. With a current retrofit rate of less than 2% per year, our existing building stock is quite the task to tackle.

We at Phius aim to make building science approachable as well as passive strategies and modeling methods that are clear, but we also recognize the need to provide structure and quality assurance to create standard programs and guidance for the architectural and related professions. It is with this lens that we endeavored to develop a retrofit standard that delivers the vital benefits of passive building: thermal resilience, comfort, healthy indoor environment, operational emissions reduction, and long-term affordability, all while being more sensitive to embodied carbon and cost implications.

The result of our work is Phius REVIVE 2024. Released in July 2024, Phius REVIVE 2024 is a reimagined framework for retrofits with a focus on resilience and decarbonization. It is designed to improve building efficiency and durability, as well as occupant comfort and health, all while balancing budget restraints and the social costs associated with embodied carbon.

Background

Thermal resilience has long been heralded as one of the principal benefits of passive buildings. With super insulated and tight envelopes, habitable interior conditions can be maintained during extreme weather conditions when active space conditioning systems are rendered inoperable. In conjunction with improvements to building enclosures, early passive solar homes also included large solar collectors and thermal storage systems that covered as much as 95% of normal heating demands. As passive building designs evolved, there was less emphasis on passive solar collectors and more on the building envelope, which led to further reductions in heating loads: relatively comfortable conditions could be maintained by the internal gains alone. While this benefit is documented, only limited guidance on calculating and modeling of thermal resilience has been available until recently.

Phius previously modeled thermal resilience and published some research on the topic, but generally these models were too complicated to be put together, prohibiting their use on most projects—especially retrofits. However, through a case study project—a retrofit proposal for a 129-unit brutalist condominium building in Washington, DC—we began to define a protocol for modeling. After testing some models on a few other projects, we noted that the resilient design could be achieved with less insulation than the new construction standard currently demanded. This led us to begin to work on a retrofit standard with this resilience modeling at its heart.

Since the launch of PHIUS+ 2015, Phius has made cost reduction a major consideration in the design methodology. Each of the models used to set the targets is a crossover WUFI model from another energy modeling tool that ran thousands of lifecycle cost analysis (LCCA) simulations to find the cost optimal balance between envelope and mechanical system investment. However, early iterations of the LCCA tool had limitations that made it unable to handle the many variations that occur in real-world projects. With updates to the software, we have overcome this limitation and now can perform an LCCA on each project. When the long-term costs relating to the damage done by each ton of carbon emissions (i.e., the social cost of carbon) are included, LCCA can be a powerful tool for showing the benefits of decarbonizing a building. Incorporating an LCCA into every project allows project teams to cost-optimize their designs, show incentive for decarbonization, and ensure the long-term affordability of the project.

Additionally, we recognize that QA/QC is critical to the success of any high-performance building project. For the past nine years, Phius has used third-party QA/QC programs that rely on RESNET Professionals and compliance with EnergyStar and Zero Energy Ready Homes. While the underlying programs change for the new standard, the focus on quality assurance in the project delivery process does not.

REVIVE 2024

The Phius team built the REVIVE 2024 program upon a foundation of resilience, cost optimization, and quality assurance. Traditional passive space conditioning metrics are being replaced by thermal resilience metrics, the source energy targets replaced by LCCA, and the quality assurance replaced by a commissioning process based on ASHRAE documents (Guideline 0.2, Standard 230, Standard 202). The specifics of the program are unique for each project—every building needs its own retrofit plan.

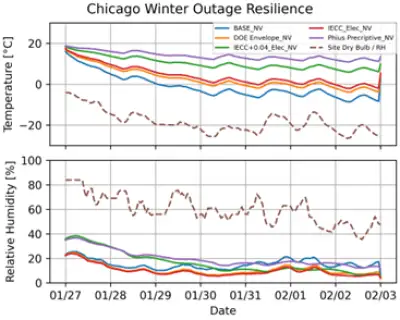

For the thermal resilience metrics, both summer outages and winter outages are regulated separately. For the winter, only passive measures (and an ERV to prevent carbon monoxide poisoning) are permitted, and the building must maintain zero hours below 2°C (35.6°F) to prevent freezing of piping and other critical building infrastructure. The prevention of hypothermia is regulated by limiting the number of heating SET (standard effective temperature, a thermal comfort metric) to 216 degree-hours.

For the summer outage, the limit is zero hours in the danger or extreme danger range of heat index, as well as zero deadly days, based on epidemiological studies analyzing mortality during extreme heat events globally. The summer outage may be met with passive means, such as shading and natural ventilation, but demand-controlled cooling can be utilized if onsite renewable energy is provided. Generally, drier climates can be made resilient through passive means, while humid climates require some active measures to reduce the humidity. All outages are 7 days, or 168 hours.

Phius has developed a new software to simulate thermal resilience during outages, an easy-to-use tool that runs EnergyPlus in the background. The tool allows for parametric simulation, so design teams can run multiple iterations to fine tune the design to these conditions.

Site hazard resilience is also a consideration, especially as the monetary damage from natural disasters builds. For this, REVIVE 2024 looks to the FORTIFIED Building standard and to FEMA guidance. This includes resilient features to hail, hurricane, flood, wildfire smoke, etc. Each hazard only applies if the building is located in a region where that hazard is possible, so a building in Colorado would not have to be hurricane proof, but a project in Florida would. All this is determined through the workbooks made freely available for download on our website.

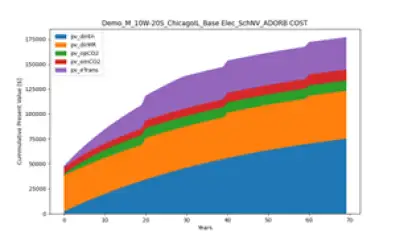

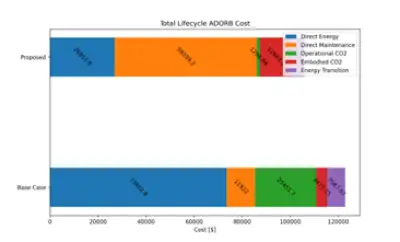

Phius developed ADORB (Annualized Decarbonization of Retrofitted Building cost) to use as a lifecycle cost metric. The ADORB cost has five components as part of the total:

· direct maintenance and retrofit cost,

· direct energy cost,

· social cost of embodied carbon,

· social cost of operational carbon, and

· energy transition cost.

The direct retrofit costs are calculated from the energy model and a cost database of different assemblies. Carbon costs are calculated using the estimated cost of direct carbon capture of $250/ton. The energy transition cost is the cost of bringing new, carbon-free energy onto the electric grid. The LCCA is also built into the software tool, which runs an annual, normal operation dynamic energy simulation to determine the annual energy consumption. The outputs of this simulation are used to determine the direct energy cost, peak grid demand for the transition cost, and operational carbon emissions by using hourly data from the NREL Cambium tool.

The whole REVIVE 2024 program is based on the ASHRAE Guideline 0.2 commissioning process to ensure quality is delivered throughout the project. As retrofits involve an existing building, there needs to be documentation of existing deficiencies and conditions that pose risks to health and indoor air quality, as well as plans made to mitigate them. There is a lot more formal structure around investigating the existing condition. The standard looks to EPA’s Energy Savings Plus Health renovation documents instead of the Indoor airPLUS new construction program.

Phius has developed various workbooks to guide project teams through this process and indicate at which points the owners and the rating authority (Phius) need to review and approve the design and documentation.

Sample Project

In order to make sure everything works effectively and efficiently, Phius has been working through some pilot projects. For the purpose of this article, we will show a single-family ranch house.

An assessment walkthrough was performed, and it was determined that the home’s vintage indicated that lead paint would not be an issue, nor did it have a lead water service line. However, the home did have a bath ventilation problem, a broken air conditioner, and moldy carpet in the basement.

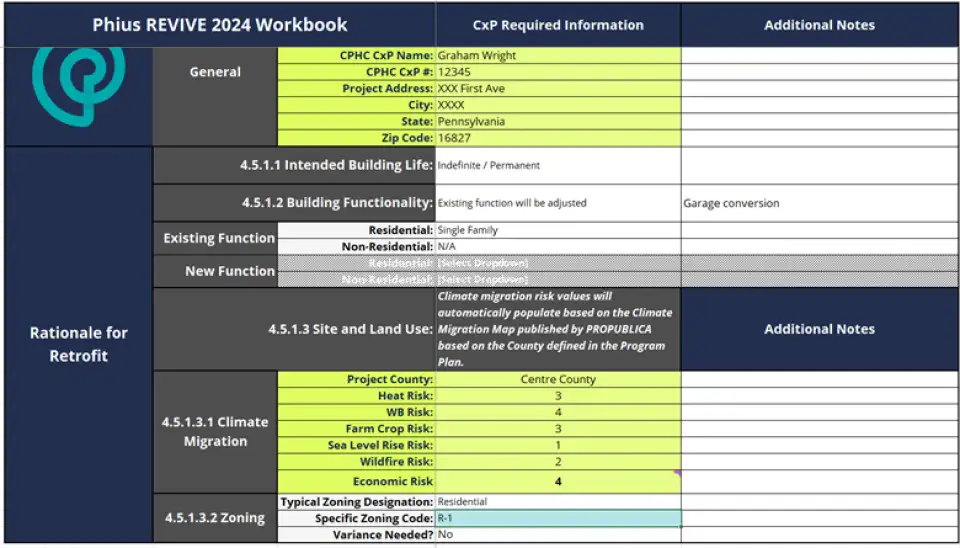

Following the assessment, the next step was to work on a rationale for the retrofit to account for migration due to extreme events. For example, if a project is subject to high sea level rise risk, there might not be a reason to retrofit the building if the expected life of the completed building will be cut short by land loss. As this home is located in central Pennsylvania, there is little risk of sea level rise or other site hazards. With the indefinite expected occupancy of the building, it was clear that this building could be retrofitted successfully.

Once the baseline data needed to run the energy model was collected, an initial energy model was created, and it did not meet the resilience criteria. Following that, additional cases were run using pre-programmed retrofit package levels: one light envelope improvement, one to IECC 2021, one to IECC 2021 with Phius level air sealing, and one to the Phius Prescriptive Path envelope requirements. The Phius Prescriptive case had the lowest operational emissions and direct energy cost; however, the cost of doing the retrofit and the involved embodied carbon pushed the total ADORB cost greater than the cost of owning and maintaining a slightly lesser insulated, just as resilient building. Meanwhile, the IECC 2021 with passive building level air sealing (0.06 cfm at 50 pa) proved to meet the resilience criteria at an optimal lifecycle cost. At this juncture, further refinements are being considered for the envelope to fine-tune the design for cost.

As the design is adjusted, the project can progress into developing design documentation, all reviewed by Phius in order to assure compliance with the program and all of the quality-of-life aspects of passive buildings such as moisture management and indoor air quality. Upon completion, the house can then be renovated, the infiltration tested, and all of the final quality assurance work completed.

Resources

The documentation for the new REVIVE 2024 retrofit program is available on the Phius website. The REVIVE 2024 standard document is the overarching document that describes all of the program requirements (both building and process) in detail and provides references for other resources for those who would like to dive further. The Certification Guidebook is the one stop manual for those certifying under Phius, with step-by-step guidance on how to work through the project, including process tips. The REVIVEcalc software is free, open source, and ready for download. Around two hours of training videos are provided to explain the functionality of the tool and how to create and simulate projects in it.

We at Phius are determined to never stop learning and innovating in the passive building world, and we will continue to update these resources as we learn more, and as we respond to changing conditions from projects. Stay tuned for more information and software updates.