Throughout North America, officials are sounding the alarm about the rising risk of major fire events and the real threat that exists to life and property in North America’s wildfire “danger zones,” known as the Wildland Urban Interface (WUI). They hope to apply lessons learned from previous wildfire activity to strengthen fire and building codes to reduce risk and prevent losses. WUI areas are those where the built environment and wildfire-prone vegetation/forested areas meet.

Ongoing population growth and urban sprawl are driving housing development in WUI designated areas. When more homes are built in WUI zones, the potential for wildfires sparked through human and natural ignition sources (i.e., lightning) rises, while the ability to battle these fires (or for controlled burns to occur) becomes ever more challenging due to a wide variety of factors including topography, density, community design and construction materials.

Approximately one in three houses and one in ten hectares in the United States are now in WUI zones. From 1990 to 2010, the number of homes in WUI designated areas swelled from approximately 30 million to over 43 million, representing a 41 per cent increase, while the WUI land area grew from nearly 225,000 mi2 to just over 297,000 mi2, up 33 per cent [1,2,3]. While more recent data is limited, the U.S. Fire Administration estimates that the WUI area has grown at an average of 2 million acres annually, which will only increases the risk to residents and stresses firefighting communities that are already struggling with overstretched resources [4].

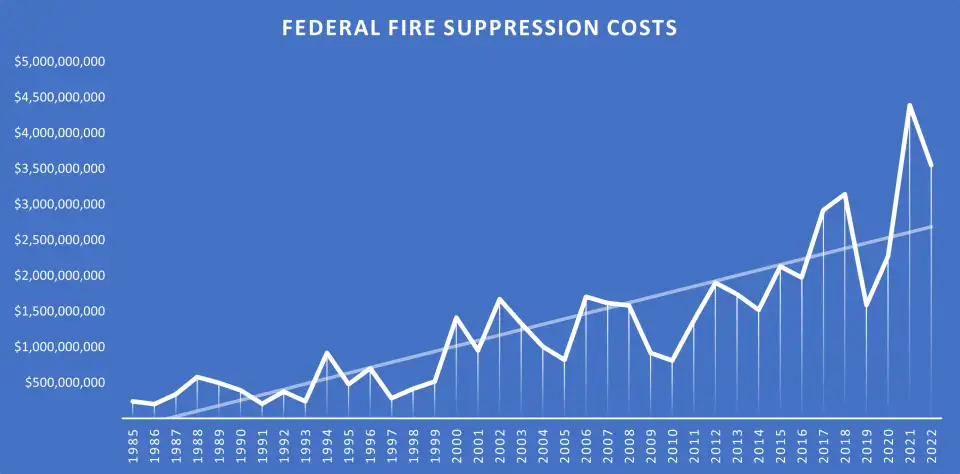

Unsurprisingly, federal wildfire suppression expenditures have risen in parallel with increasing development in WUI areas (see Figure 1). Expenses have risen from approximately $240 million in 1985 to just over $3.5 billion in 2022, a fivefold increase when figures are adjusted for inflation [5]. Insurers have also experienced tremendous losses. In 2018 alone, insured losses reported by the California Department of Insurance topped nearly $13 billion [6]. This represents just a fraction of estimated 46 million homes in WUI areas valued at approximately $1.3 trillion across the U.S. [7]. Given that the continued population growth in WUI areas, in conjunction with a trend toward higher temperatures, lower rainfall, and a longer fire season overall, the cost of inaction is potentially tremendous.

To mitigate risk, officials are seeking to improve the built environment, with a focus primarily on new construction, in an effort to improve the likelihood that homes in WUI areas and the people who occupy them might have a greater chance of survival during a fire event. Building to higher standards in terms of fire resistance and ignition resistance are the primary goals of the WUI code.

Defensive Strategy

To design and build a house that has a greater chance of surviving a wildfire, carefully selected building materials and careful attention to details must play a significant role in prevention. Two of the greatest threats to homes include direct flames/radiant heat and embers. While the latter may seem like a lesser risk, high winds have been demonstrated to blow hot embers up to a mile from their source, igniting fires that can cause significant losses. The WUI code sets out the specific requirements for certain parts of a home/structure and property to ensure it is WUI compliant. Building products used to achieve compliance or as part of a compliant assembly must be listed as approved products in the WUI Building Materials Listing Program or have undergone testing to demonstrate the product/assembly meets WUI requirements. Components covered by WUI code include exterior components such as roofs, walls and siding, decks, windows, doors, soffits and vents, and other details considered to be vulnerable ignition points. WUI code also addresses the requirement to create defensible spaces around homes/structures, including vegetation management and fuel management to prevent fire spread and make it easier and safer for firefighters to tackle a blaze.

About the Code

Local or state WUI codes are typically modelled after the International Wildland Urban Interface Code and adopted in whole or in part, often with additions accounting for specific regional considerations. While WUI code can be very similar across most jurisdictions, WUI code and code requirements may vary depending on location and wildfire risk. The requirements for fire and ignition resistance may be covered by a variety of code references.

Design/Build Challenge

While meeting each requirement outlined in the WUI code may seem as straight forward as addressing it with an approved solution, WUI can present some challenges to the design/build community.

The first and most obvious challenge is that any product used to satisfy a WUI code requirement must be demonstrated to meet that requirement—officials will require all supporting documentation including the results of recognized testing. In California, many approved products in compliance with Chapter 7A are listed in the Office of the State Fire Marshall’s Building Materials Listing Program.

Yet, it must be noted that not all products or solutions are listed in the WUI Handbook—even if they’ve been previously approved for use. It is recommended that designers and builders check with manufacturers regarding approvals/documentation. Products not listed may still be approved for use, if the case can be made to local or state-wide code officials that the product(s) or assembly are in compliance. To have a new product or assembly approved can be a challenging process, a reason it is typically initiated by manufacturers. However, the design community sometimes plays a leadership role to champion innovation, particularly when it will result in a more advantageous solution for their project/structure.

New Product Approvals – Convincing code officials, championing new solutions

A case from several years ago in the state of California stands out. Forward-thinking design firm, Sagan Design Group, wanted to break from a status quo WUI solution to meet requirements for the exterior wall assembly (2016 CRC – R337.7.3). Typically, designers are limited to tested assemblies for various sidings (usually must use a rated assembly). Generally, those who do not wish to use a rated assembly must instead use 5/8” Type X gypsum sheathing under the exterior cladding to act as an ignition-resistant barrier in order to achieve WUI code compliance or have an alternative assembly/solution tested. Sagan Design Group sought to use a continuous layer of exterior mineral wool semi-rigid board insulation instead of Type X gypsum, highlighting another key builder challenge: compliance with all the various codes—in this case the WUI code and the Energy Code, which do not consider one another. Often, solutions will meet one code, but will not help address the simultaneous requirements of another—there isn’t necessarily a handbook or listings guide that tackles that.

In California and across the U.S., energy codes have been growing stricter (and will continue to grow stricter still), requiring tighter building envelopes with lower U-values that address air leakage and thermal bridging, respectively. Sagan Design Group was met with the challenge of achieving the 2016 Energy Standards, approximately 20% – 30 % more stringent than the 2013 Standard, while also meeting R-value targets and satisfying WUI requirements. Tim Melin, P.E., a civil engineer with the firm, states that while a number of solutions exist, it was getting more difficult to satisfy all codes simultaneously.

As a result, the ability to meet California Energy Code without continuous exterior insulation is becoming ever more difficult, and in the future, as code tightens, continuous exterior insulation is likely to become standard practice.

While continuous insulation was an important part of meeting the existing energy code, there is some debate about adding to a home’s potential fuel load in WUI zones even now. Foam plastic products, when ignited, burn rapidly and produce both heat and toxic gases, contributing to the potential fuel load for a fire and allowing it to burn more intensely and for longer [8]. Yet, foam insulation can be used within an assembly and still meet WUI requirements when covered with Type X gypsum, although it requires a wall system with more layers (foam insulation plus 5/8” type X gypsum). Melin notes that that’s where the case for continuous exterior mineral wool sheathing board proves to be strong. The mineral wool continuous exterior insulation can simultaneously achieve WUI compliance without the need for gypsum—eliminating a layer within the assembly and potentially reducing install time, labor, and costs—and also meet energy code requirements.

A Trailblazing Solution

In making its case to local code officials, Sagan Design Group and ROCKWOOL™ demonstrated that the continuous exterior mineral wool sheathing board (ROCKWOOL Comfortboard® 80) provided the non-combustible, ignition-resistant performance benefits equivalent to Type X gypsum, while also delivering a wall system that reaches necessary R-values and contributes to the strict U-value rating. The mineral wool continuous insulation also proved further advantageous, allowing for a wide variety of cladding options, a benefit that would also sit well with homeowners who often insist on specific materials to achieve a certain aesthetic. Additionally, it helps achieve a wall assembly that is breathable and hydrophobic to water, helping to guard against moisture issues.

While many other options are possible (there are no one-size-fits-all solutions), designers continue to face challenges in meeting the array of more complex requirements, and there are barriers. For example, software modelling programs of performance-based models make it difficult to model some solutions such as offset studs, making it more difficult and time consuming to get alternatives passed. Meanwhile, when meeting energy code, it is becoming near impossible to employ a straight prescriptive method. It’s no longer enough to target the low hanging fruit such as improving mechanical systems, water heaters, or components like windows to improve performance to the standard now required—not to mention, this doesn’t even address simultaneous codes such as WUI regulations. As a result, the new low-hanging fruit is insulation—continuous exterior insulation to be precise.

Sagan Design Group worked directly with mineral wool insulation manufacturer ROCKWOOL, building a case filled with data, testing, documentation, code references, certifications, and more to show building officials that not only could mineral wool boards be a critical component in meeting WUI requirements, they could also replace Type X drywall all together under cladding in the exterior wall system. In the end, local officials approved what might end up being a trailblazing solution. Not long after, ROCKWOOL Comfortboard® mineral wool exterior sheathing board received certification in California in the State Fire Marshall’s Building Materials Listing Program (BML).

Resistant to fire up to 2,150˚F with a 0/0 Smoke Development and Flame Spread rating, Comfortboard® has met or exceeded strict standards in fire-related product performance testing. The State Fire Marshall’s BML Program certifies products based upon an evaluation of test results that include an analysis of required product performance and reliability features. All testing for ROCKWOOL product was completed with a State Fire Marshall (SFM) accredited laboratory.

Given the direction of energy codes and the need to satisfy both energy and WUI requirements, it seems inevitable that the residential built environment may be on the cusp of change driven largely by code compliance. It’s undeniable that how we build is, in fact, changing. However, in embarking on the approval process, the teams from Sagan Design Group and ROCKWOOL found that there were currently no approved assemblies utilizing continuous exterior insulation in existence in the WUI Building Materials Listing Program. Both the firm and the manufacturer worked hard to amend that. Documentation is available outlining the certification and the full testing results for ignition resistance and 1-hour system testing on relevant assemblies using ROCKWOOL mineral wool for the California market.

“We need to build smarter to meet the more complex demands of today’s building codes and standards,” notes Melin. “We’re now building for structure, energy, safety, moisture management, and air/vapour considerations. Products need to be versatile. Mineral wool semi-rigid exterior board sheathing in the form of continuous insulation is a serious multi-tasker. With it, we can meet WUI requirements, we get energy performance, comfort, sound control, breathability, hydrophobic properties, and compatibility with a wide range of other components.”

This example shows that we can build better within WUI areas, whether in California or beyond. WUI code in itself isn’t the greatest challenge, although it can be a hurdle. The main challenge is meeting WUI requirements plus the complex array of requirements inside the rest of the suite of building codes. What that means is that designers and builders will need to look to building products that do more. They’ll need to use their experience to continue to do what has always driven the built community forward: thinking beyond the status quo. Better solutions should also pay off for homeowners as well, with more durable, resilient buildings that require less energy and less maintenance and/or remediation down the road.

Codes and standards will continue to evolve. As the built environment moves forward, designers, builders, manufacturers, and code officials all play a pivotal role in proving that as we build today—and more importantly, in how we build—we can reshape tomorrow.

References:

Radeloff, V.C.; Helmers, D.P.; Kramer, H.A.; Mockrin, M.H.; Alexandre, P.M.; Bar-Massada, A.; Butsic, V.; Hawbaker, T.J.; Martinuzzi, S.; Syphard, A.D.; et al. Rapid growth of the US wildland-urban interface raises wildfire risk. Proceedings of the National Academy of Sciences of the United States of America (PNAS) 2018.

https://www.arcgis.com/apps/MapJournal/index.html?appid=82c9a07d6a7147a98b4efbe68428defb

https://www.nifc.gov/fire-information/statistics/suppression-costs

Press release – California Department of Insurance – May 8, 2019 https://www.insurance.ca.gov/0400-news/0100-press-releases/2019/release041-19.cfm

https://www.usfa.fema.gov/downloads/pdf/publications/wui-issues-resolutions-report.pdf