THE PROBLEM

A good design does not stop at a building. A good design seeks; what is next? It was this very question as a Designer that led to the birth of developing the Window/AC prototype for Bronx Pro Group (the client) to create a simpler cooling element to move away from the limited market cooling products in Passive House designs while working at Curtis +Ginsberg Architects. The Window/AC prototype led to reimagining and simplifying the cooling in the design that simultaneously addressed the need to have it more affordable, controllable, smaller targeted air-conditioned options that would also assist in building maintenance and operational cost to be low in Passive House design. In addition to this, the building’s electrification loads were important because the design needed to comply with the Primary Energy load of <6200 kWh/person/yr to meet the PHIUS standards. Since the application of the window AC unit in a Thermo Tech window had limitations, it led to an apt opportunity to invent a solution.

THE APPROACH

Install a window AC in a certified Passive House window that can be closed when not in use and kept open when in use.

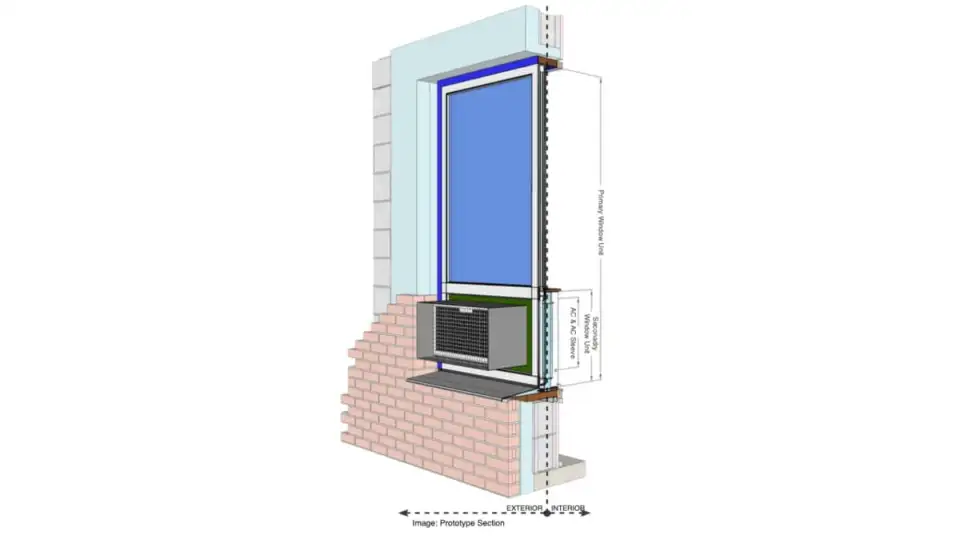

The prototype concept was to make the certified PH window (Intus Window) to act as the Primary Window Unit frame because it was high performing and thermally broken with a U‑value of 0.16 Btu/(h.ft2.°F) and connect it with the Secondary Window Unit making it performative as part of the Passive House Envelope.

The parameters of the prototype would respond the same way to three different window configurations as part of the design also.

The advantage of this approach was that the window AC unit provided a variety of manufacturers alternatives, the cooling loads would be sized correctly for all the rooms, and AC units were incorporated in the facade design language in a holistic way.

PROTOTYPE DESIGN REQUIREMENTS

In response to the facade design and building code the prototype of the AC window design was studied and analyzed to meet the following requirements :

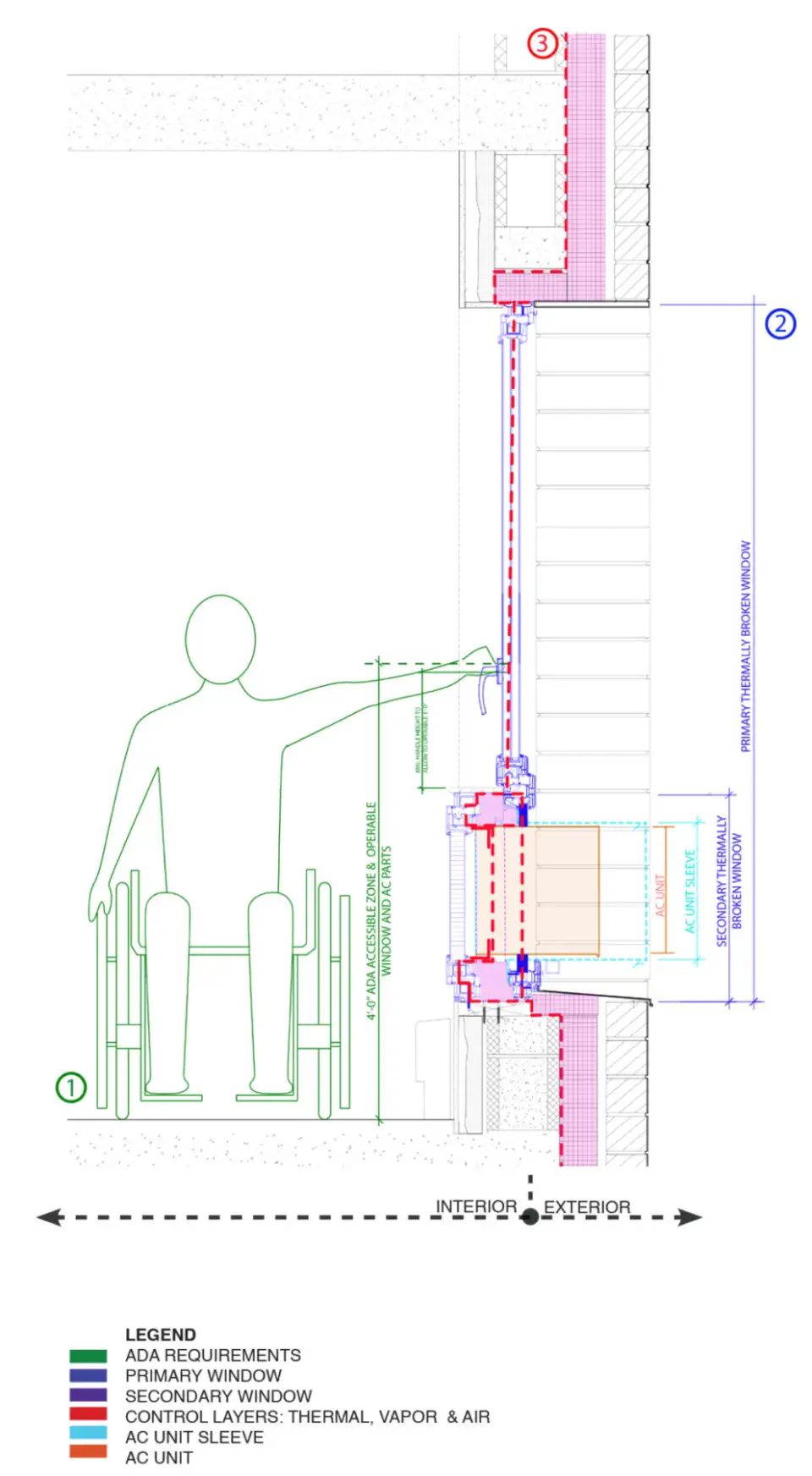

ADA forward reach requirements to be accessible on the interior side for the window and the air conditioner unit. Also for the window unit to meet the Department of Building Code to provide light and air requirements in the tenant unit.

Prototype: A certified Passive House window becomes the primary window component that is further developed with the introduction of the secondary operable window unit housing the AC. The design intent is to develop a prototype working as a singular unit that will simultaneously incorporate ADA experience and the form of the prototype to be a design aesthetic of shapes that help in shading the facade.

Building envelope: Connecting the window AC prototype back to the building envelope control layers; air, water and thermal so the prototype passes the airtightness and blower door test for the Passive House.

THE PROTOTYPE INSTALLATION

The Building envelope window opening is ready to receive the window. The opening has been covered with continuous flashing that connects back to the air barrier on the outside.

The Primary Window Unit is installed internally. The Primary Window Unit is a clip window system that is anchored to 2x4 pressure treated wood blocks in the interior wall with the continuous rigid insulation.

Once the Primary Window Unit is installed, a continuous backer rod,caulk and window tape is applied at four sides.

The Primary Window Unit lower component is designed to have a prefabricated rigid insulation panel that is :

a. Cut to an opening size to receive the AC sleeve and AC.

b. The window tape is installed around the opening connecting the window frame and the rigid panel opening so there is no air infiltration.

c. The AC sleeve is inserted into the insulated rigid panel from the interior.

d. Note it is important that the AC unit be installed at an xx degree angle so there is no back drainage and the AC unit can drain.This is followed by the installation of the Secondary Window/door from the interior of the building where it is aligned to the Primary Window Unit.

Rigid insulation is cut to shape and sandwiched between the primary window 1 and Secondary window/door 2 frame to prevent thermal bridging and keep the frame warm.

Caulk is continuously applied around the rigid insulation at the intersection meeting the frame of window 1 and window/door 2.

At the interior side of window 1 and window 2 the corners are taped first.

And then followed by the long run tapes that overlap by 4”.

Same process is repeated on the exterior side.

The window installation is complete and the interior finish can be completed.

The guts of the window AC are removed for the AC can perform and does over heat.

The Window AC Protype is complete.

RESULTS

Data, Data, Data.

The moment of truth in measuring the data is always a nerve-wracking experience with the potential of failing or passing. In this case the building must meet the envelope air leakage requirement of 0.08 CFM50/sf of the envelope per PHIUS requirements for a building of this size. The result is performed at a positive and negative pressure difference of 50 Pascals and the final result is the average of the two tests. The preliminary window testing results showed about 2 CFM50 per window. This amount of leakage is in line with the 0.08 CFM50/sf target for the building, meaning that the building as a whole has potential to pass the final blower door test. The entire testing for this Prototype has been conducted by Steven Winter Associate team and can be found on their website.

LESSONS LEARNED

From this the following lessons were reinforced:

Believe in the Concept.

Collaboration of Construction Teams & Designers to achieve the final result.

Early testing of prototypes to evaluate details is crucial.

To me the Window AC prototype was more than a design response. I envisioned it as a Window AC prototype that could be used in both new Construction and Retrofits projects and would morph accordingly where it is smarter, simpler with more prefabrication pieces and easier installation for future projects. And, this is all true as Bronx Pro moves ahead with this approach in future projects.

Finally, adapting is key for a healthy future whether it is responding to a Pandemic or changing the Energy code to come up with solutions that allow you to be creative and groundbreaking.