Harvest Thermal is about to launch a new controller for home heating and hot water that takes advantage of abundant midday carbon-free electricity to dramatically reduce residential emissions and lower customers’ bills. Completing its pilot phase, the Harvest Pod™ has demonstrated it can transform an ordinary heat pump-based system into a smart system that helps homeowners make the switch to all-electric, comfortably and affordably, while capturing the cleanest, cheapest off-peak electricity.

At Harvest Thermal, we began by asking ourselves a series of questions. Just how far can heat pump systems go in reducing emissions from heating and hot water—including the associated carbon emissions from electricity usage? And, can heat pump systems compete on price alone against fossil-fueled alternatives, while also delivering high levels of comfort? Given that the emissions profile of the electric grid varies significantly throughout the day, with carbon-free solar energy mostly available in the middle of the day and wind energy at night, how can electric solutions be operated to minimize carbon emissions?

After installing the Harvest Pod™ in five Bay Area households, the numbers say it all: over the past winter, carbon emissions in these Bay Area homes have been cut by about 90% compared to when they relied on gas appliances and by roughly 50% compared to standard heat pumps, while reducing bills and meeting all the hot water and heating needs of the households (see Table 1). And, with just one SanCO2 air-to-water heat pump, a hot water tank, and the Harvest Pod™, the upfront equipment and installation costs are compelling; a panel upgrade is typically unnecessary. In a clear win for household budgets, with built-in load-shifting, users can take advantage of the lowest electricity rates, driving down bills.

Building on our pilots’ success, the Harvest Pod is being deployed in up to 31 demonstration sites in partnership with the California Energy Commission and Peninsula Clean Energy in late 2021 to early 2022. Commercial deployments of the pod will start in early 2022. So, let’s take a look under the hood at a Harvest system and see what it does.

The Harvest Innovation

The Harvest team has systematically optimized every part of the Harvest system for the 4 Cs of cost, comfort, control, and…carbon. At its core is the pod—the brains of the system—a smart controller and integrated unit, developed after years of research, that delivers on the promise of supplying very low-carbon heat and hot water.

Table 1. Pilot Performance for Forced Air systems, January–May 2021

|

Site 1 |

Site 2 |

Site 3 |

Site 4 |

|

|---|---|---|---|---|

|

Home characteristics |

2,700 ft2 |

1,260 ft2 |

2,100 ft2 |

3,100 ft2 |

|

Number of occupants |

4 |

4 |

3 |

6 |

|

System efficiency |

320% |

280% |

270% |

320% |

|

CO2Emissions Reduction |

||||

|

Harvest / Standard Heat Pump |

48% |

49% |

57% |

58% |

|

Harvest/ Standard Gas |

90% |

93% |

91% |

90% |

|

Cost Savings/ PG&Ev2-A-Rate |

||||

|

Vs. Standard Heat Pump |

26% |

18% |

29% |

36% |

|

Vs. Standard Efficiency Gas |

45% |

36% |

28% |

31% |

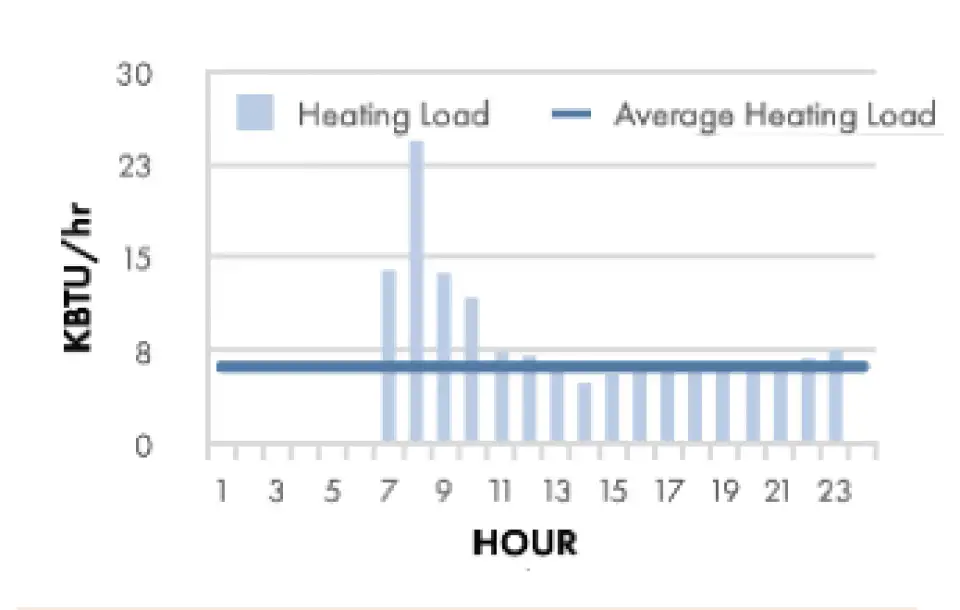

First: thermal storage. Our research has shown that a standard storage tank holding high-temperature water—combined with the right controls—can fully decouple heat delivery from the time of heat pump operation for most households, allowing the heat pump to operate using the cleanest, cheapest electricity while delivering heat and hot water whenever needed. As a further benefit, the tank’s thermal storage acts as a buffer between the heat pump and the distribution system, so that peak heat delivery to the home is no longer limited by the instantaneous capacity of the heat pump. As long as the tank has been pre-loaded ahead of peak needs, heat delivery is constrained only by the capacity of the air handler or radiant floor. This means that heat pumps no longer have to be oversized to meet the peak hourly load, but can be sized instead for the peak daily load, saving on equipment and panel upgrade costs (see Figure 1).

Second: the heat pump. Harvest Thermal uses just one air-to-water heat pump—the SanCO2, chosen for its low global warming potential refrigerant—to deliver all heating and hot water needs for a typical mid-size home in northern California. With the capacity to deliver roughly 300 kBtu per day, a SanCO2 comfortably meets the need of most homes, with the tank and distribution system buffering for peak loads.

With heat delivery separated from heat pump operation, the key climate question becomes, When is it best to operate the heat pump from a cost and emissions perspective? The pod answers that question and more. Not only does it operate the pump when renewable energy is most abundant, it takes the outdoor temperature into account to maximize heat pump efficiency, avoiding heating up the whole tank unnecessarily when the heating load is small or zero, and managing timing to minimize duration of storage and hence thermal losses. The pod’s system control adds up to optimized performance and efficiency and minimized costs.

Third: heat distribution and hot water. Harvest systems support forced air or radiant floors for heat distribution, with the pod managing flow rates and fan speed to provide variable heat capacity while optimizing the return water temperature to keep the SanCO2 heat pump operating at maximum efficiency (see Figure 2). It also maintains a reserve for hot water and replenishes it to avoid runouts. While the system operates without user intervention, its boost feature, vacation mode, and guest mode provide the flexibility to meet changing needs.

Harvest Pod: the brains of the system. The common thread in the operation of this combined system is the Harvest Pod, which unites the electronic controls and such mechanical components as pumps, sensors, and valves. The pod operates and optimizes the performance of each of the component devices, coordinating their operation, while maintaining sufficient buffer to allow adjustments for changes in needs. It is a single compact unit that fits on the wall of a garage, mechanical room, or in a water heater closet.

The pod is critical to keep system installation costs down and competitive with a conventional heat pump system. Standardization and factory assembly and testing cost a lot less than custom and error-prone onsite plumbing and testing.

This system is a welcome addition to electrification strategies, expanding the options for non-fossil-fueled heating and hot water, with the benefits of cost-effective storage, and with cooling to be added to the list in the future. For more information, contact [email protected].