According to C40 Cities, urban communities account for nearly 70 percent of the world’s energy consumption and CO2 emissions. While new building construction today is more likely to incorporate an energy efficient strategy from the outset, the real opportunity lies in deep energy retrofits of aging building stock. C40 also asserts that energy renovations can provide up to 55 percent of the GHG emissions reduction needed to reach the 2030 targets of the Paris Agreement and align with a 1.5 ̊C trajectory.

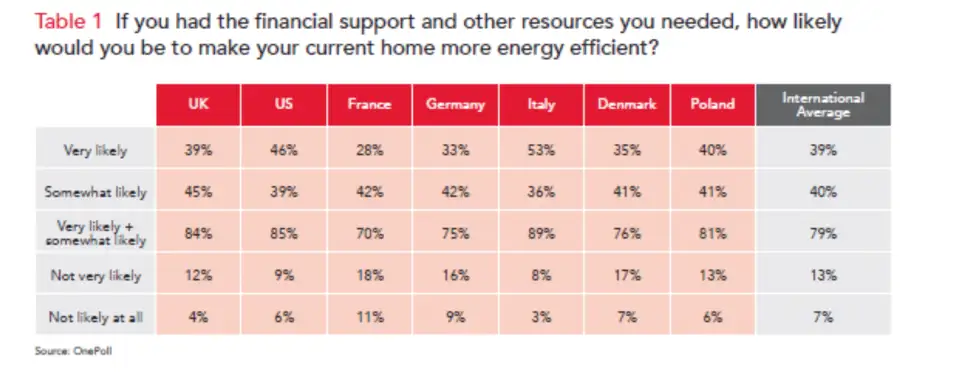

And where once the push for decarbonization came from environmental activists and a handful of policy makers, today there is a swell of public support for action. The trend is confirmed in a report released late in 2021 by ROCKWOOL Group and Cambridge Econometrics; the report maps a clear path to greener buildings and shows strong support from the public to renovate their homes, if adequate financial and administrative support is available. Including data from a global first-of-its-kind survey of 14,000 people in the United States, Denmark, France, Germany, Italy, Poland, and the United Kingdom, the report confirms the public appetite for energy efficient buildings, while also showcasing the need for governments to develop fit-for-purpose renovation programs.

The polling by OnePoll shows eight of 10 people (79 percent) would renovate their home, given the right assistance. In an even stronger show of support for greening the built environment, 73 percent believe energy efficiency improvements should be mandatory, provided financial and administrative support is available. Sixty-two percent believe it is their social responsibility to make their homes climate friendly, given the same support is available.

The Building Envelope is the Key

There is a lot of talk among conservationists and sustainability advocates about tapping into cleaner energy sources as well as smart technology to help reduce the carbon emissions from building stock. There is definitely room for a holistic approach to battling climate change, but all the clean energy and smart technology in the world aren’t going to solve the problem of reducing emissions if buildings are leaky and wasting energy. And thankfully, architects, builders and policy makers are recognizing the importance of the building envelope in the equation, both for new builds and retrofits, with improvements to energy codes as well as the materials and strategies used in their construction.

The building envelope affects approximately 50 percent of the energy demand of typical buildings; therefore, implementing envelope-related energy conservation methods (ECM) are an effective way to reduce energy demand and operational carbon emissions of a building.

What Needs to be Considered in a Retrofit Plan?

When deciding on enclosure-specific ECMs, consideration for thermal efficiency, durability, structural capacity, and constructability, among others, is necessary. Therefore, understanding the unique challenges of different building envelope retrofit options is critical to ensure appropriate solutions are applied.

Thermal efficiency: Existing buildings—whether commercial, institutional or residential—will typically have little to no insulation within the envelope, resulting in excess heat loss and increased energy consumption. More importantly, they usually have poorly installed or non-existent air barriers, making them very leaky and further increasing energy waste. The addition of insulation in exterior walls and roofs, combined with an appropriate air barrier system, is integral to improving building performance, reducing leaks, and creating more comfortable indoor environments. When it comes to the assembly’s thermal efficiency, we must consider the system's overall effective thermal performance, not merely the insulation layer's nominal thermal resistance. This means accounting for the thermal resistance of all applicable layers within the assembly and calculating reductions caused by thermal bridges.

Durability: One of the critical benefits of retrofitting buildings is that we can increase their lifespan. The added longevity and durability of an envelope and the energy savings they create are a way to justify the upfront costs. Considerations for an enclosure's durability include assessing the primary control layers, in particular those related to water and moisture management. It is critical to ensure that appropriate drainage and drying measures, and vapor diffusion control considerations are in place, as poorly designed retrofits may lead to unintended moisture damage.

Constructability: Simply put, a retrofit strategy's constructability relates to how simple it is to install and execute as well as the overall cost. In practice, each retrofit is unique, with no one approach to rule them all. Upgrading the building envelope can introduce different constructability challenges, depending on the building site and existing condition. The strategies applied will vary and cannot necessarily be used on all projects in the same manner. One common thread that does connect all projects, however, is people. Therefore, an effective strategy must also consider the impact on occupants.

Aesthetics: While very subjective, a building's aesthetics is often a primary concern for the architect, building owner and occupant. For existing buildings, the retrofit strategy may require the aesthetics of the façade to be altered or left untouched altogether. With more product options available for meeting retrofit goals, including stone wool batts and rigid insulation boards for both interior and exterior applications, increasingly a building’s aesthetic design doesn’t always have to be sacrificed for performance.

The Building Envelope is Only as Good as the Sum of its Parts

Exterior walls: Various applications within the building envelope will each have unique requirements that support the building’s retrofit goals. For example, plans to improve a building’s exterior wall insulation will need to consider the potential impact of cladding and attachments on a continuous insulation system, as well as moisture control strategies to ensure the sheathing selection works in tandem with vapor-open stone wool insulation to maintain its superior drying ability, rather than trapping moisture.

Note that a rainscreen over-cladding system using stone wool insulation can use various substrates, providing versatility and design freedom for architects and designers. Depending on the cladding type and weight, the overall desired insulation performance, and thickness, they can be accommodated with either thermally broken intermittent clip and girt systems or directly fastened through the stone wool insulation. Likewise, over-cladding solutions using stone wool insulation provide versatility in design and cladding options along with additional fire resistance. Non-combustible stone wool insulation has a flame spread index and smoke development index of 0. It does not trigger assembly testing, such as NFPA 285, even near other buildings, such as in dense metropolitan markets.

Interior walls: An interior wall or cavity-only insulation upgrade must account for large thermal bridges; here, consider floor and roof insulation around the walls' perimeter, although these are not as effective as a continuous exterior insulation solution. When working on the enclosure's interior side, ensuring continuity of the materials and their transitions is more complex, requiring attention to assembly detailing.

Masonry walls will present unique challenges when retrofitting as they are heavy and porous, allowing them to store moisture. Because older masonry walls often do not have insulation, the wall's energy transfer makes them dry inefficiently. Therefore, adding interior insulation will change the wall assembly's temperature gradient, which can be detrimental in winter conditions. Also, masonry walls often do not have a dedicated air barrier system and can be very leaky.

Therefore, airtightness is vital for the retrofit design, especially since interior air leakage can condense on the cold brick and cause potential moisture concerns and mold on the newly created interior finishes. Similar conditions apply to other mass-type walls such as pre-cast concrete, tilt-up, or concrete masonry unit where there is no existing insulation. In these situations, building science experts advise using semi-rigid stone wool insulation boards for a continuous interior layer of insulation. The dual-density characteristic of semi-rigid stone wool boards provides a soft backside enabling an easier install against uneven surfaces and a higher-density exterior surface for a more robust exterior finish.

Flat roofs: Most existing buildings that are ready for a roof retrofit have insulation levels below current energy standards. Although increasing the thermal performance to current standards may not be necessary when conducting roof renovations, it can be critical for energy savings. Depending on the retrofit strategy, this may be achieved by adding a few additional inches of insulation over the existing roof, or it may require a full re-roof (tear-off). Roof systems are subject to higher and larger temperature fluctuations, meaning their membranes and insulation materials are subject to expansion. For example, foam plastics are at more significant risk to thermal deficiencies caused by gaps and holes due to thermal expansion and contraction, along with their in-situ climate-dependent thermal performance.

For roof remediation systems incorporating additional insulation, choices will vary depending on the new membrane type. Adding stone wool insulation in a recovery system helps improve the roof's overall durability and thermal efficiency if the existing insulation is in poor condition and gaps are evident.

In a full re-roof application, the new insulation system can be either full-depth stone wool or a hybrid roof design, incorporating a layer of stone wool insulation over a base layer of insulation. This solution can also comply with updated wind load and fire testing requirements. Full re-roofing is optimal for buildings with a high roof-to-wall ratio where most of the heat loss occurs through the top, and there is a favorable cost-benefit.

Ken Soble Tower is a Prime Example of What’s Possible

The deep energy retrofit of Ken Soble Tower in 2021 is a perfect example of what is possible with deep energy retrofits. The multi-unit residential building was completely upgraded, inside and out, to achieve (EnerPHit) Passive House standard, reducing greenhouse gas emissions by an impressive 94 percent and achieving a 91 percent reduction in annual heating energy demand. After learning what would be possible with stone wool insulation solutions, the architects completely changed the original plan for the building envelope.

The resulting cladding design included a 6-inch thick stone wool EIFS system that helped them meet the steep targets of the retrofit. The design helped bolster climate resilience and durability as well as thermal comfort, safety and indoor air quality while reducing operating costs. Overall, the retrofit served to preserve affordable housing stock and restore it as a vital asset in Hamilton City Housing’s portfolio and within the community.

Deep energy retrofits are no longer a lofty ambition, and with increasing buy-in from home and building owners, it’s time to move it from promising principle to conventional practice with a holistic, envelope-first approach.

Photo courtesy of Cordin Talaba