Passive House’s relentless focus on operational energy in buildings has sometimes relegated upfront carbon emissions from building materials to an understudy role—but that’s changing. Increasingly the best-laid climate plans for the building sector are addressing both operational and embodied emissions. Are you ready for the new black?

Attend Passive House 2020: Choose Your Future to learn how to adapt and turn your prospective projects into carbon sinks in presentations from Chris Magwood, a director at the Endeavour Centre, and Matt O’Malia, executive partner at OPAL and cofounder of GO Lab.

For how long do upfront carbon emissions in building materials outweigh operational energy savings? That question so obsessed Magwood that it became the basis for a two-year research study, earning him a Master’s Degree from Trent University in Ontario in the process. His thesis, Low-Rise Buildings as a Climate Change Solution, is chockful of modeled data comparing carbon emissions from various building materials, along with other approaches to slashing emissions from the building sector.

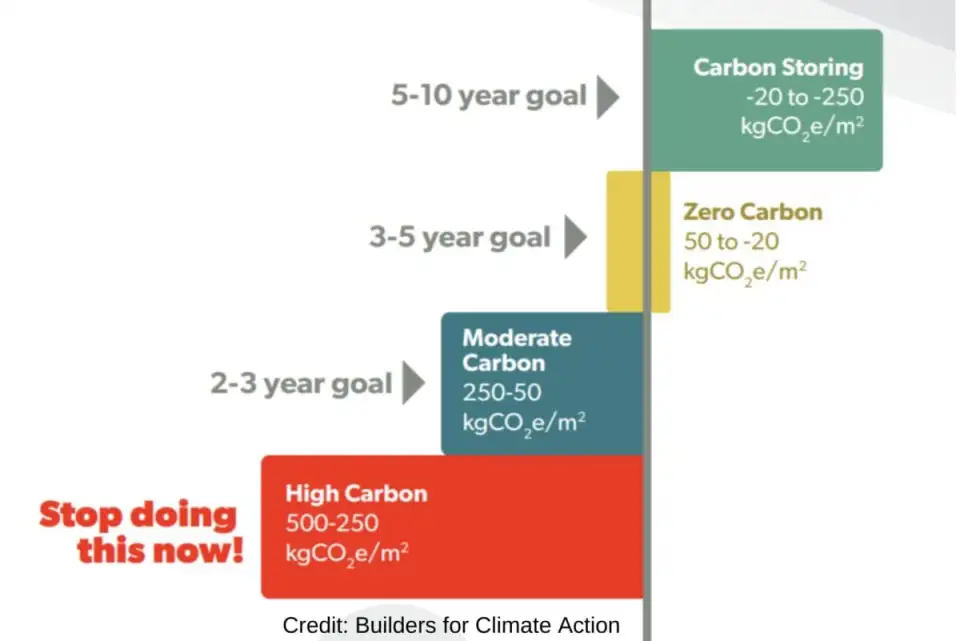

“Climate change departments have had their eye on embodied carbon for a while but didn’t have numbers that made it actionable,” explains Magwood. His work caught the attention of the municipality of Douro-Dummer, which became the first to turn his data into an incentive program. The city’s program helps defray permitting expenses for projects that reduce the combination of up-front and operational emissions, otherwise known as the carbon use intensity (CUI), of a building. Other local governments will be following Douro-Dummer’s lead. The City of Toronto is already considering amending its ambitious retrofit program to incorporate CUI assessments.

Magwood will be discussing which changes in building materials can yield the most benefits. As a sneak preview, think cellulose and wood-fiber board insulation. “Those materials can get most residential buildings down to a zero-carbon-net footprint,” says Magwood, “And those materials are accessible here.”

By 2021, that accessibility will escalate, thanks to efforts by O’Malia. In addition to running a cutting-edge architecture firm, he has been striving to bring to market a born-in-the-USA wood fiber-based insulation. “It’s a solution,” he says. It’s also been an eye-opening process, he admits, raising the capital with his partner at GO Lab, Josh Henry, to turn an abandoned paper mill in Maine into a factory outputting loose-fill, batt, and tongue-and-groove insulation boards, all made from wood fiber.

This massive project stemmed from O’Malia’s use of building life-cycle assessment (LCA) tools, starting in 2017. The more informed he became about the total impact of his projects, the more mindful his decisions could be. To this day energy modeling and LCA modeling are deeply embedded in his design process. “They should go hand in hand,” says O’Malia, adding that both types of modeling raise awareness of the impacts of our choices as architects.

At Passive House 2020: Choose Your Future you can get the details of how O’Malia used these tools to inform his decisions during a recent project, a 30,000-ft2 academic building.