Passive House construction has come a long way in just a few years, especially in North America. Historically, Passive House has been more common in Europe, but changing codes and greater attention to the climate crisis has accelerated its adoption in North America. Given that buildings account for nearly 40% of annual carbon emissions and Passive House drastically reduces a building’s operational energy use by up to 75%, it’s no surprise that the Darmstadt-based Passive House Institute (PHI) and Chicago-based Phius are certifying an increasing number of projects. As of January 2023, the Passive House Institute had certified 37.5 million square feet of usable area, while the square footage of Phius-certified projects doubled between 2021 and 2022, from 600,000 to 1.2 million square feet.

While the building science behind Passive House construction can get complex, the core principles behind the methodology are relatively simple. There are five: continuous insulation, thermal-bridging-free detailing, superior windows, mechanical ventilation with heat recovery, and airtight construction. When all five are in place, the result is a quiet, efficient, comfortable, healthy, and durable building.

In this blog post, we’ll focus on the importance of airtightness:

Its role in construction

Its role in Passive House construction

Where air leakage occurs

How grommets work

The benefits of airtight grommets

We’ll also learn about Partel’s new line of airtight grommets, many of which have been phA certified.

The Role of Airtightness

Within the world of construction, airtightness refers to the barrier separating the outside from the conditioned (i.e., heated or cooled) interior. A building that is not airtight will have a barrier with holes, cracks, and gaps. Airtight construction methods strive to eliminate or at the very least minimize these openings. Consequently, within an airtight home conditioned air stays inside and unconditioned air remains outside of it.

While airtightness may not be flashy, it is the unsung hero of high-performance building and energy efficiency. Conversely, when a building is leaky because it has not been properly sealed, it leads to significant energy waste. In fact, air leaks are estimated to be responsible for almost 25% of final energy use by buildings in the United States.

You can learn more about airtightness here.

Airtightness in Passive House Construction

With Passive House construction, buildings are so airtight and well insulated that they remain comfortable with limited active heating or cooling measures. This translates into dramatically lower utility bills, even when outdoor temperatures are at their most extreme. Additionally, a combination of airtight construction and mechanical ventilation makes sure all the air that is allowed into the building first passes through a filtration system that keeps out allergens and dust, as well as bugs.

Airtight construction also contributes to the building’s indoor air quality and durability by providing moisture control, ensuring that wall assemblies remain free of mold, protected from the elements, and operating at peak performance.

Where Does Air Leakage Occur?

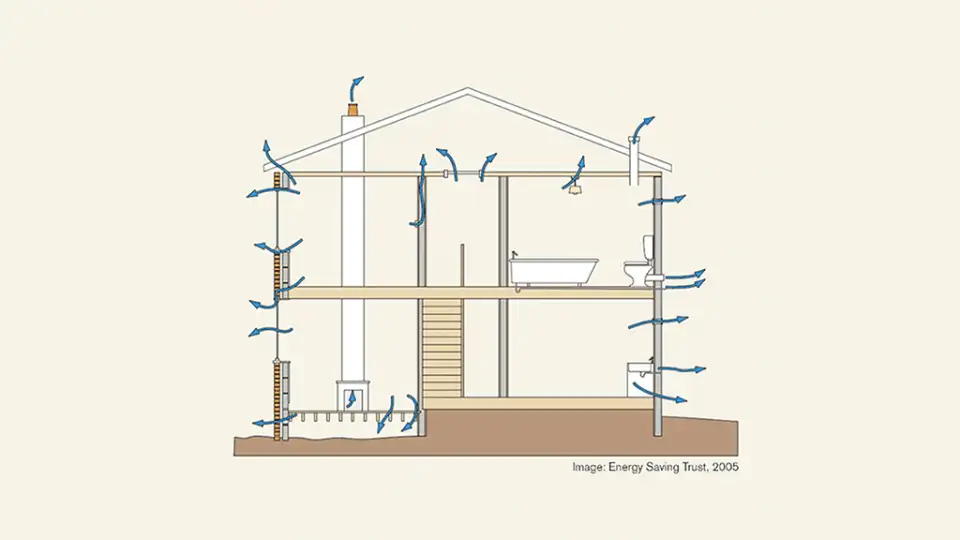

Virtually all modern homes are built with an airtight layer or barrier to minimize air leakage. When these airtight layers converge, they need to be sealed to ensure that the barrier is continuous. Unfortunately, conventional construction methods do not always prioritize sealing these junctions, resulting in leaks. Some of the most common junctions that are not properly sealed are where the walls and windows meet, where the walls and floors meet, and where the walls and roof meet.

Another common site of air leakage occurs where pipes, ducts, and cables pass through the air barrier. These are known as service penetrations. Left unsealed, even small service penetrations can be a drag on performance as air passes through the tiny space between the airtight barrier and the pipe, duct, or cable. For someone striving to achieve a high level of performance or Passive House certification, they can also be time-consuming, costly, and difficult to go back and fix with tapes or fluids.

Grommets and Airtight Construction

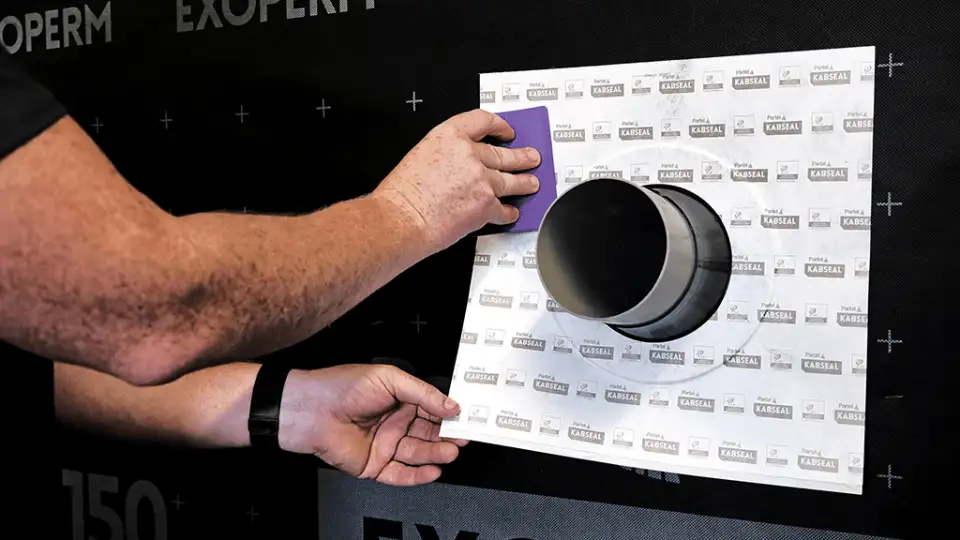

Grommets have long been used to provide reinforcement to holes that have been punched in leather, drapes, or shower curtains. However, grommets serve another purpose in high-performance construction because they help eliminate gaps between the air barrier and the perimeter of wires, cables, and ducts and preserve the integrity of the air barrier. Grommets may be self-adhesive, meaning they can be applied directly to the air barrier and maintain a continuous seal, or they may need to be taped. Either way, grommets are integral to preventing air leakage and bolstering performance.

Partel’s New Line of Airtight Grommets

Recognizing the importance of grommets in high-performance building, Partel—one of the leading manufacturers of air and windtight systems—has launched KABSEAL, a comprehensive range of airtight grommets for cables, pipes, and conduits that can be used to improve performance or prevent the permeation of radon. The KABSEAL line relies on cutting-edge materials science to ensure a secure and airtight seal in residential, commercial, or industrial settings, and many of the individual products, including KABSEAL PRO, KABSEAL PRO 6, and KABSEAL GAS have been certified by the Passive House Institute.

Airtight Cable Grommets

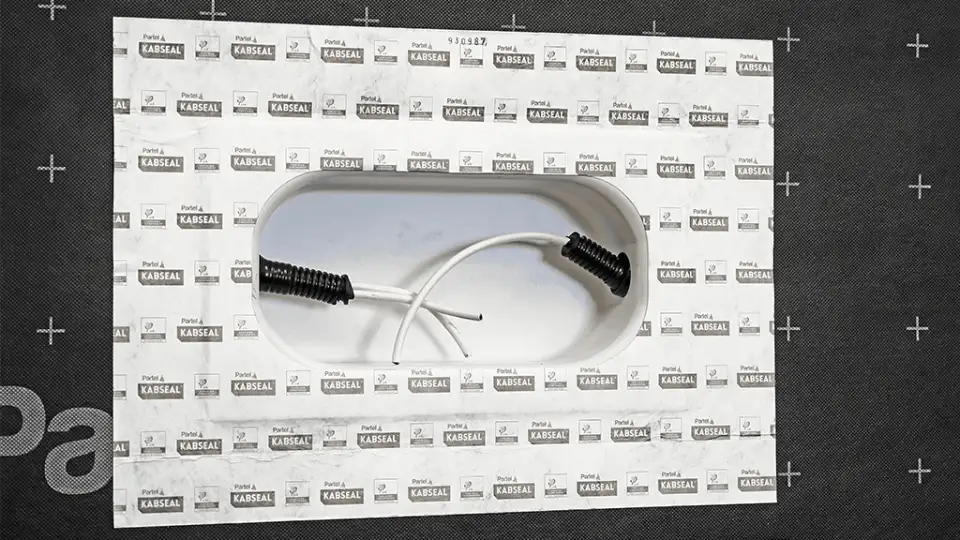

KABSEAL PRO and KABSEAL PRO 6 offer reliable solutions for sealing cable penetrations. They are available in multiple dimensions and are suitable for external and internal use. While KABSEAL PRO is designed to handle individual cables, the KABSEAL PRO 6 can accommodate multiple cables and make installation a breeze.

Airtight Pipe Grommets

KABSEAL PRO and KABSEAL HEAT seamlessly fit around a wide range of pipe diameters to eliminate leaks. KABSEAL HEAT is a heat-resistant grommet that has been designed to seal exhaust pipes and other temperature-sensitive openings.

Airtight Conduit Seals

KABSEAL CAP is Partel’s airtight seal around multiple cables within a conduit. Available in a range of sizes and capable of accommodating a multitude of conduit dimensions, KABSEAL CAP facilitates smokeproof and airtight connections during electrical installation.

Airtight Radon Grommets

KABSEAL GAS and KABSEAL SLAB are both designed to provide an airtight seal around pipe, cable, and supply line penetrations in radon mitigation systems. Additionally, Partel has introduced KORNERSEAL GAS, which simplifies the task of sealing corner connections. An essential component to keep radon from infiltrating living spaces, these grommets are easily installed, durable, and ensure the health and safety of occupants.

Airtight Back Boxes

Partel has also introduced ELECTRISEAL BOX, a flexible and efficient airtight housing for electrical back boxes that can accommodate up to 3 sockets. It is designed for internal use and ensures accurate and permanent airtight electrical connections.

Conclusion

This post has described the importance of airtightness for energy efficiency and achieving Passive House levels of performance. It’s also shown that grommets play a vital role in maintaining the integrity of air barrier systems and ensuring that homes stay airtight, comfortable, and healthy.

To learn more about the KABSEAL systems or to obtain technical specifications, check out the KABSEAL page of Partel’s website here.