View the video transcript below:

Satpal Kaur:

I'm really excited to share this project and basically be here with you all. And it's one of my favorite projects that I've actually been part of in terms of enclosure thinking and really kind of, was really privileged to think of it in a different way. So before I begin, if I don't know of anyone, I really would love to learn all about all of you guys soon. And as Bev's already done an intro for me, I feel I have, other than me being a passionate designer and designing energy efficient, passive house buildings for over 15 years, I think for me, it is a learning skill. I'm always surprised. I've always liked this idea of continuing to be surprised by my work, have an open mind. And I think that's what makes designing buildings with building science super challenging. And I always say to people it's like being part of a science experiment and this particular presentation that I'm going to do today On The Sea, I changed the name is based on the SS US ship.

Satpal Kaur:

It is a study that we did for RXR in collaboration with HLW, because of the ship's unique typology and the fact it was not on land, but a floating metal structure keeping itself dry, to me was very exciting. And having this opportunity to merge Naval and traditional architecture to reinvent the ship as a different use, as meeting today's climate needs as well, it was really like an interesting challenge in terms of enclosure thinking, and what does it mean? And just really kind of working with a team in terms of, could it be delivered on achieving it to net zero or what type of things are we looking at it? And surprisingly, I got to work with a lot of the pioneers who designed the ship like Gibbs & Cox, et cetera.

Satpal Kaur:

And it was really an interesting experience, just learning about the skeleton of the ship, which I'll be speaking with today and just thinking of different typologies for the envelope. And with that, let's begin.

Satpal Kaur:

So the SS US ship is a monument, it's an ambassador and it's the pinnacle of mid-century maritime design and artistic achievement. It's the world's largest ocean liner, a smashing speed for its time. So it really is quite phenomenal. It's also transformative. It's been a national security asset, capable being transformed again to the state of the art security military vessel as well. So it's a living icon of different stories, which has emerged from World War. II. It's carried people from small towns to big towns, setting out on journeys, and it's also stories about immigrants crossing the sea, beginning new lives. So for the ship, the SS US ship, it seemed quite relevant when we were looking at it for it to be transforming itself yet again.

Satpal Kaur:

And what really excited me about this particular project, and when we're talking about resiliency, when we're talking about how can we reuse ships in a different way? What if the most advanced building is a ship? Well, how does it... For its time, it had pioneered different type of generation, and different generations systems thinking, could it still do the same? Reducing its carbon footprint. Does it live itself on the ship or does it be something that's plugged in on site? Is there a destination of the future? What if buildings are not capable of making us future proof? Do we have to look at other ways that we have to achieve this? So for me as someone being part of this, like thinking of future proofing and designing in a very different way, I was really excited to kind of break down what the actual envelope and the skeleton of the ship was.

Satpal Kaur:

And as we started looking at it, because of its distinctive envelope, we realized that the superstructure plate functions as both at the air barrier of vapor barrier, which is kind of strange because for a metal, you don't normally expect that, but then it makes total sense when you think, oh, of course there's no water that comes inside the ship when I'm inside the ship. And obviously, I'm constantly dry too. But then it is something interesting when the case of the ship in a cold climate, the envelope has to perform to resist the interior airflow that will stop the convective loops that you'll see at the bottom and at the size of the section of the ship itself. And this is because it forms a double hull and these convective loops like part of the super structure, it's not really the wind that's causing it, it's actually just because they're just hollow.

Satpal Kaur:

So that was really kind of looking at how do we think of it as a retrofit versus like, okay, we're just going to go in and just change the look of ship because it was an icon and we didn't really want to do that. And we knew what worked with systems. We knew we needed a complete air barrier and it had one, technically speaking, because the outside of the superstructure was acting like that. But it also needed to have some form of compartmentalization, which we know is also helps in terms of performance. So taking these... And it would also reduce the convective loops that you know, was happening alongside these, the actual hull or the skin of the ship as well. So we started digging down further into the actual ship and what, how it was generally constructed because you know, we needed to obviously place a lot of systems.

Satpal Kaur:

We needed to insulate it. And how do we do that? Because we were also lacking height. We didn't have much height to run a lot of duct work, and we definitely didn't want to reduce interior space as well. So as we started looking at the ship, it actually consists of this series of bulkheads and they serve as a way of like, you know, if there was any kind of water that would enter, it would just like drop down, as you see over here and that would just prevent water going from the next to the next compartment. So there were 20 watertight compartments and out of the 20 watertight compartments, you had eight of these bulkheads. But what I saw in this was more than that. And this is right at the beginning. What I saw instead was, wow, these are these hollow spaces.

Satpal Kaur:

This is great. This is what I need. And I need this to run systems. And what happens is from the whole deck, so it is no longer first floor, second floor, third floor, the language completely changes. So you have to speak the language, what the ship is. So in this case, in the hold, you have this double, the double hull, and then once you get to the B deck, which is like above, now emerging out of water itself, just about here, the actually, the double hull actually changes and I'll show you what I mean by that.

Satpal Kaur:

So this is a section cut. So these are the series of the structural grid of the existing ship that runs continuously, which acts as, we will say to some degree, compartmentalization, the watertight bulkheads, et cetera. But what happens is it goes from being nine inches all the way from the hold to C deck, and then it becomes six inches and then smaller. And that was the opportunity that we needed really to run a lot of these systems that we were thinking, obviously not from the bottom, but could we use this double hull frame as we're retrofitting it to run electrical, the mechanical, and even the installation, like how could we utilize this space, which is not really being used, but we, you know, reinventing this whole thing about what is this space going to be.

Satpal Kaur:

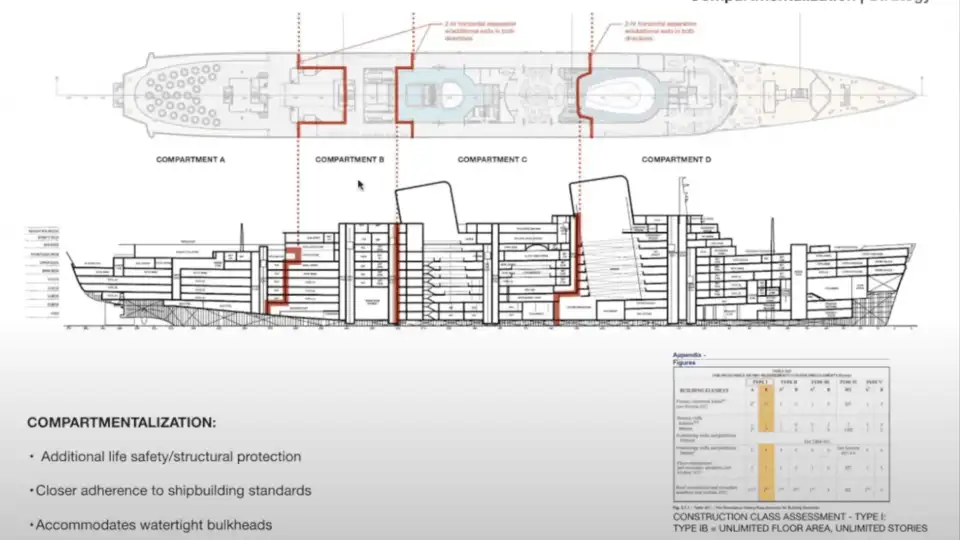

And so in terms of... So we firstly looked at ways existing ships were doing compartmentalization because some of the programming of the space meant that we had to look at our space differently, too. And just with buildings, I was seeing a very similar language, how we would say, for example, you would have the unconditioned space where you would run a lot of the mechanical systems and obviously above you'd have a lot of the conditioned spaces running, and this is how they pretty much do it in the Marine Naval world right now. And it works as, you know, it's actually kind of interesting how they look at this as a division of main vertical zones by thermal and structural boundaries, obviously fire risk categorizations that they have. And for the ship, because it was going to be a building, we had to translate it into the building world.

Satpal Kaur:

And because we were translating it to the building world, we decided it was going to be at the time, you know, what was the thing? It was type one that it fell into. And because of that, we could, if we wanted to construct as high as we needed. But what we identified instead is, we were going to use the existing bulkheads that they have, which are highlighted in the dark red, and we were going to run them all the way through, down to the actual hold itself. And these will act as major, as a 4... 1, 2, 3, 4 compartments that would actually form as compartmentalization instead. And that kind of helping us like how we were thinking about the systems in general. Sorry, that was too fast.

Satpal Kaur:

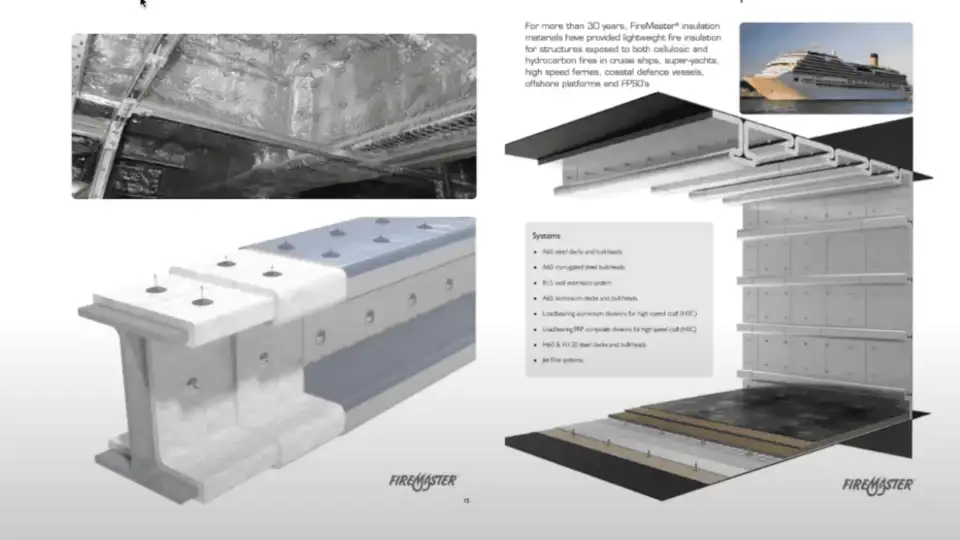

So that helped in terms of what we were thinking, where the systems would be running, because in the same way we had compartment A, B, C, that would be the same way we would have electrical, mechanic, all of these would have their own electrical, mechanical, et cetera, in these same compartments. So it wouldn't be, they would be a crossover, et cetera. And then with the existing insulation that they have for new ships, it's actually fairly interesting. So they have what they use is a A60 Marine board and they pretty much use what we would say, you know, just put that envelope, just cover it with every... This would technically, I guess, be your thermal fire rating, everything, mineral that they would just follow the whole structure around it, cover it up for fire, cover it up for thermal, and then they would run anything that's needed.

Satpal Kaur:

And to me, this was great, however because our ship was old, we couldn't really technically do as much as the things that the new ships would, because we would obviously be applying a lot of fireproofing on it and then working backwards, from all that. So it was then we were back at the board and looking at it in a very different way again. But this helped in the sense what we could achieve looking at the technologies that they already had.

Satpal Kaur:

So with the idealized enclosure that we kind of already know that forms a good performance in a wall is when you start having, you know, you have the finished layer outside, try to have your thermal layer on the outside and then have your air control, vapor, et cetera, just before that structure, just because you can control around things. In the case of the ship, everything changed because here we had that red line was basically the outside of the ship itself, which was my air and my air control layer, and that had to be super tight. And in the case of the ship, it has these series of flaps, which I'll show on later in the section and they had to also be air tight as well. So we had, the way we were thinking of it, because we wanted to run the systems in this double hull, we were like, okay, so we will kind of do that, the smart vapor wall system here and just try and, you know, calculate it and make sure everything is going to be performing as we would do with any kind of high performance building.

Satpal Kaur:

And this was a section that I had to take at the time to RXR to basically convince them they needed to do this. And I was super nervous because I had never had done a ship before, but I knew how to design obviously high performing buildings and I knew how to make them work. So I was like, I'm going to use that same strategy on a ship. So what do I have? I've got nothing to lose, so might as well go with it. And so I did the enclosure line just showing them, we're going to run the insulation just as you would do, but this is obviously a retrofit, running inside of the double hulls. And then we would compartmentalize each of these spaces on the left hand side and the right hand side for whatever purposes or the programming would be.

Satpal Kaur:

And because I'm a huge fan of unitized system, my first proposal was like, why don't we unitize, have a unitized system, therefore the ship can potentially, you know, we don't have to introduce so many systems for it to be relying on huge mechanical work, et cetera. They were obviously not fond of that because there would be holes introduced, but you know, so we went back, but you can see there's a way of running a lot of these things on the inside and then along the actual, the double hull itself. And this is the same way that it would be same in any kind of high performance buildings, you have the ERV just going straight out and then you'll have the heat pumps doing their work. So we formed a hybrid in the next one, which is basically, we decided to go with the air source heat pump instead and everything, just including the mechanical, the electrical, all of the systems would run on the outside skin of the double hull itself.

Satpal Kaur:

And instead of like actually living on the ship, we would actually have it plug into the main land. So a small building would be produced for that, so you would have, for the most part, the building would be able to... Oops, why does my mouse, sorry, keep doing that. For the most part, the building would be able to work by itself. And this was a success for a variety of reasons because it meant that we could do the installation. We could run the systems. We wouldn't reduce. There would be no.

Satpal Kaur:

Sorry. Can you hear me? Sorry. So you wouldn't actually lose any of the headroom as well. So this, with this thinking, we actually moved forward with the ship thinking how to design for it. And so that's the plug, it's all be plugging in back to some of the mainland, but most of the generation, sorry, most of the electrical plumbing, et cetera, would just be, we would have a vacuum system that would actually get the toilets, et cetera.

Satpal Kaur:

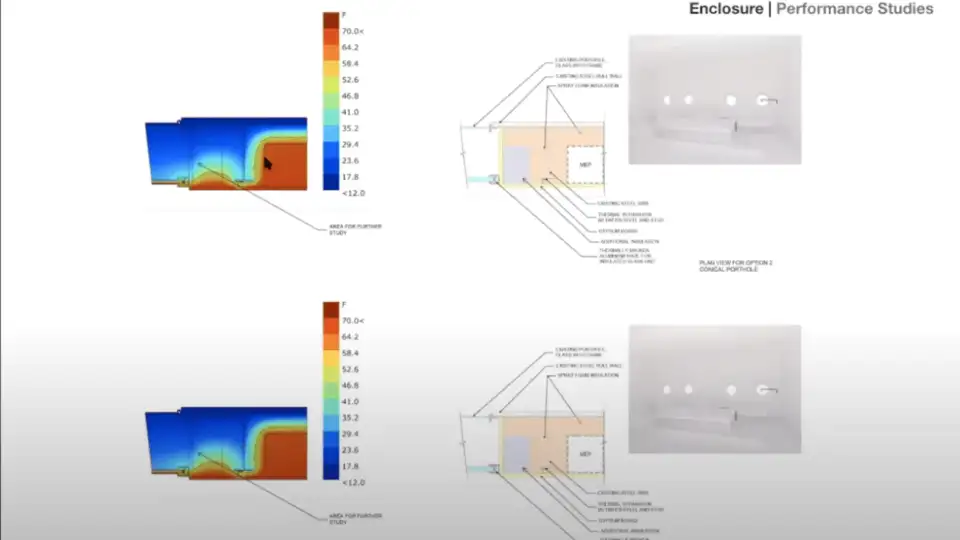

So most of this, I can't only show big picture-wise because we are still in the process of finishing most of this off. But when it came to the enclosure, we had three different ways of looking at the enclosure of the ship. And this is one of the plans and they all change because obviously the nature of the ship is that the enclosure is not like a wall. It's not straight everywhere, it's going to change. And because it changes at the bottom of the hull itself, we actually, the first one that we had, the baseline approach, we were pretty much following what they would normally have done. So because the double hull is quite thick, we would actually say, okay, fill it up with some kind of stone or water, whatever you need it, because the ship needs to balance itself.

Satpal Kaur:

And then on the outside they would just have the spray form. And then after the spray form, closed cell installation, the air gap, green grit, thermally broken clips holding the mineral wall, which is very common in ships that they use and staggering it, and then forming another air gap and running then the final finish coat. In the number two, the ones that you see over here running instead, what we proposed was different. We said, okay, for this one, can we just not use a continuous Marine grade coating, which they used anyway. Which serves the hull fire coating, which serves as an air barrier at the same time. And let's just run that all the way from the second steel plate instead. And we just did everything using mineral wool. We didn't actually introduce spray foam at all. And instead for the smart vapor barrier, we proposed with this green line that you see over here, we actually proposed a quad zero ML instead.

Satpal Kaur:

And then again, the air gap and so forth. For the last one, the alt two, what we decided was that since the ship's unique nature of the curvature, could we just potentially just, you know, we have the technology you now, can we just not 3D scan this thing and the final enclosure is just put on? Like we just use these series of slots, they just get introduced and that's it. And it's actually not as simple as I would love to say, because it obviously becomes a much more of an expensive project, but definitely an interesting one.

Satpal Kaur:

And then when you come up towards the higher decks, which is the promenade deck and the sports deck, the ship is no longer as part of the double hull system. And you can see this in plan now where it's actually offset from the deck itself, sorry, from the hull itself. And the way we had to think about that was literally like a building. It had to be, you're going to be putting a building on there. So how do you make that building air tight? And that to me was fascinating because that would be this whole floor from basically promenade onwards, it would just be compartmentalized altogether. So the floors below that would actually act as its own volume and then the floors above would become its own conditioned space.

Satpal Kaur:

These are some therm studies that we had done and when we were looking at understanding how the ship is performing and obviously, it be cold because it's metal, and when you add installation, it starts behaving better, which we all have known, but it's good to see that still. And so it allows us to understand where we could improve and how we can design differently with the ship. This is a section of that therm as well, where we get to see that cold and hotspots. So obviously we have some thermal bridging happening there. How to like again, you know, putting it back there, understanding it better. These MEP things would no longer run here. They would pretty much run in this space over here, instead.

Satpal Kaur:

And one of the things which, as any designers with a ship of this nature, they really wanted to embrace the whole ribs that the ship had. So with the main hull, expressing the ribs became part of the design thinking too, then therefore it became part of the enclosure thinking, and kind of how do you make this system still work when you want to make it high performing, when you want it to reach a net zero, when we're trying to not be wasteful with a lot of things around us. And it really meant for something like this, we had to go back to that whole 3D fabrication system just because of the nature of the shape of the ship.

Satpal Kaur:

And we continued with the same thing saying, hey, okay, it has this air barrier. Over here, it has a series of laps and each lap as the ship's made, they'll just get a series of air seal done on it so it's completely tight. And then after that, we'll do the hull fireproofing and then the spray foam and put foam blocks around the windows here. And this is a section of sorry, a plan and a section showing this.

Satpal Kaur:

So that's pretty much big picture-wise, what we try to do in a very intense period just before COVID. And it was a lot of work, a lot of like scrambling and one of the things that was interesting just when I was saying just about when you get to the promenade deck, things change. And one of the exciting things that we got to do with this was okay, so the king post, which is very much part of the ship and the way people are seeing the ships, could we reuse these king posts? And I'm a huge fan of reusing pretty much anything a designer can do. So with this, I had to do a lot of convincing cause I was like, why can't we just not run a lot of the ERVs through our king post because it doesn't serve anything.

Satpal Kaur:

It's just there. It's not really doing much. I mean, we used it for structural reasons in terms of putting out a cable of support system so it kind of looks like the whole ship is coming out and we wanted to kind of be more part of its history, to be technologically forward thinking, really embracing that. So I proposed let's just go all the way. Let's run the ERVs running through the king posts we have, one will be the return, one will be the supplies. This particular programming space that we had designers in is capable of having the air source, small heat pumps actually been part of the roofless design, a different type of roof where the air source heat pump can sit on the roof and we can vent it out. it doesn't have to be something that's treated as separately. And that to me was really exciting, because all this would be obviously coming in, being prefabricated elsewhere, and basically being put onto the ship itself.

Satpal Kaur:

And it was these systems that a lot of people, especially with air source heat pumps now becoming more available, it was a lot of just investigating what is the smallest, smallest size we can get? How do we get this looking as minimum as possible? How does it fall with the aesthetics of the design and still be revolutionary in what the history of the ship is? So that was the actual promenade deck itself that we got to propose this for. And then this is how it would be if you wanted to ever get married or redo your vows. This is how it would look from the inside. So these will be your king post and this will be the time you actually take your vows and have that perfect time.

Satpal Kaur:

Oops, oops, that's too fast. So one of the iconic things about a lot of these ships is, especially the older ones, this is the life boats of these ships and they're amazing. Unfortunately, you know, they are there, but they're not usable. And I really was interested in creating a very different way of looking at this with our team. And so we kind of saw it as a car technology instead, where you will still be able to enter these series of life boats, but a different type of experience. And what we proposed instead is they will keep the same kind of square footage of the existing life boat, and you'll be able to access them from the promenade deck, which are these over here, and you'll just enter straight in. And it has again the same principles of any high performance building where we would run, just like any car, you would have that whole insulated shell but this would just have that shiny metal stuff.

Satpal Kaur:

And it just be something that just comes on. So you'll have the enclosure with the insulation and then the whole air barrier system. And we would run majority of the systems, at least for the plumbing, et cetera, would run here. And for the ERVs would actually hold them there. And we would just vent them straight up from the top of the cabana itself. And this is a view of the going towards that. So you kind of get to experience this new and old and you still get to have the structural being intact.

Satpal Kaur:

And this is a view from the inside. So even though you may have the old boat, you still have the experience of, you know, I'm sorry, the experience of the, you have the experience of the new version of it. And so one of the things I liked about this particular project was, and I realized as I was working on it, it really was a retrofit and it didn't really occur to me as I was working on it because a ship just, it just seemed like a ship but I guess, you know, it is a retrofit project.

Satpal Kaur:

So one of the things I find interesting when I look back at this, can buildings be done like this? When we're thinking about resiliency, are the other objects, other than buildings that can still form this? And because it seems as though it's doable, we have the technology now. We have different ways of thinking about it. And as flood levels continue to increase, like how, what are the different typologies that we're putting out there, which might not normally be that are considered buildings and they become buildings and this was one of them and I'm super excited to see what they, what are the next steps for this? So we'll see. And so far, this is where we are as we just hold tight with COVID. But thank you. So much.