By Jay Fox

For more than a decade, 475.Supply had been a scrappy startup renting a small, single-story space in Brooklyn. Like many of the other light industrial buildings on the block, the exterior was windowless and accessible through a heavily graffitied garage door. Casual passersby would have had no idea that behind this rough exterior was a team driven by a mission to build like the future depends on it by learning how to properly use and install an ever-growing catalog of high-performance building products. Each new partnership brought in more products that the 475 team had to learn how to use, and the space became a testing ground where many of these items were assessed or even installed before being offered to customers.

“A GC could walk in, and you just point and say, ‘This is how you install the tape,'” says Brink Team Manager at 475.Supply Gabrielle O’Grady.

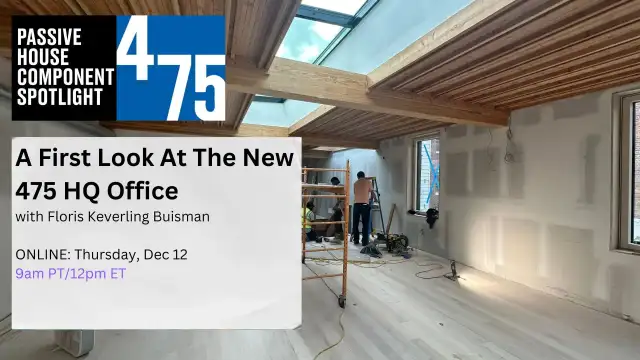

Though it was an ideal incubator for a startup, the team at 475 recognized that they were outgrowing the building, and so they purchased what would become their new headquarters in 2023. Located just six blocks from 475’s previous Brooklyn headquarters near the Gowanus Canal, the new location at 369 Warren Street was a mix of brick and CMU with a concrete slab foundation. The L-shaped building contained a garage space on the first floor that extended deep into the property and held five cars (including one owned by a celebrity), while the second and third floors were home to a single duplex apartment above the front portion of the garage.