As we’ve explored in other blog posts, Passive House design is informed by five principles, which include: airtight construction; continuous insulation; thermal-bridge-free detailing; high-performance fenestration (windows and doors); and balanced, mechanical ventilation to provide a constant supply of fresh and filtered air. In addition to reducing energy consumption, buildings that are constructed to the Passive House standard increase thermal comfort and have superior indoor air quality compared to code-built homes, since they filter out dust, mold, allergens, and many pathogens.

While all five of the principles of passive construction are necessary to receive Passive House certification and to create a building that is truly efficient, durable, and comfortable, and Partel’s many lines of products help builders achieve Passive House levels of performance, this blog post will focus on thermal bridging. We’ll cover the following topics:

What is thermal bridging?

Where does thermal bridging typically occur?

What are the effects of thermal bridging?

What is thermal-bridge-free design?

What are thermal breaks?

How ALMA Vert can be incorporated into thermal-bridge-free design.

What Is Thermal Bridging?

When one typically thinks of heat loss in a building, they tend to think of a drafty window or door or possibly the cracks in the walls. While this is a major source of heat loss, it’s most certainly not the only one.

Homes also lose heat through what is known as thermal bridging. When there is a significant difference in temperature between the inside of a building and the outside, heat will follow the path of least resistance. In a thermal bridge, the “path of least resistance” is not a metaphor; it is literally a narrow path within a building enclosure where energy is transferred from the inside to the outside (or vice-versa when it is hot outside and cool inside).

To use the phrasing found on Passipedia, which is basically the FAQ page for the Passive House Institute: “A thermal bridge is a localized area of the building envelope where the heat flow is different (usually increased) in comparison with adjacent areas (if there is a difference in temperature between the inside and the outside).”

Where Does Thermal Bridging Typically Occur?

Thermal bridging is created in building assemblies where one material is more conductive than the surrounding materials. For example, thermal bridging will occur along a steel stud if it is not insulated. In fact, the framing of a home is the most common source of thermal bridging. Junctions (e.g., ceiling-to-wall, balcony-to-wall, window-to-wall) are another common source of thermal bridging, as are joists made from concrete, steel, or even wood. Thermal bridging can even occur when anchors or fasteners like nails, screws, or staples penetrate insulation barriers.

What Are the Effects of Thermal Bridging?

While the most obvious result of thermal bridging is that it makes a heated space cooler or a cool space warmer, thereby requiring more energy to maintain the same temperature. As a result, thermal bridging leads to less thermal comfort and increased energy usage, which in most cases means increased utility bills and carbon emissions.

As thermal bridging affects the surface temperature of the material where the bridging occurs, this can lead to not just cold spots, but increased condensation on surfaces and the incursion of moisture into wall assemblies. In extreme cases, condensation can lead to frost damage, but the far more likely and insidious result is mold growth, which becomes more likely as the relatively humidity increases. Mold poses health risks to occupants and, if not addressed, can lead to structural damage, as well as rot and decay in wood structures.

What Is Thermal-Bridge-Free Design?

The good news is that thermal bridging and all the associated problems can be prevented with thermal bridge free design, which is one of the principles of Passive House construction. As the phrase indicates, thermal-bridge-free design accepts that a certain amount of heat loss is inevitable in any building but largely eliminates the paths of least resistance that occur with thermal bridging. From a more theoretical perspective, thermal bridge free construction is when the total heat loss from all the thermal bridges within the building is not greater than the cumulative thermal transmittance of all individual components.

Continuous insulation substantially reduces thermal bridging, but it is not enough on its own to achieve thermal-bridge-free design. Advanced framing techniques, high-performance fenestration products, and thermal breaks also play a significant role in eliminating thermal bridging.

What Are Thermal Breaks?

Thermal breaks prevent thermal bridging by disrupting the transfer of heat through conductive materials, typically by introducing materials that are significantly less conductive and have greater thermal resistance. As a very clear example, think of a copper pot that has been on a hot stovetop. The pot is designed to get hot and transfer energy to cook whatever is inside. The handle of the pot, meanwhile, is designed to do the opposite. It is typically made from material (most often plastic) that has a very high thermal resistance, disrupting the flow of heat and preventing it from flowing from the pot to your hand.

Thermal breaks in construction operate using the same principle. They break the bridges, ensuring that homes stay comfortable and free of condensation.

Discover the Future of Sustainable Building with Partel's ALMA Vert Thermal Bridging Solution

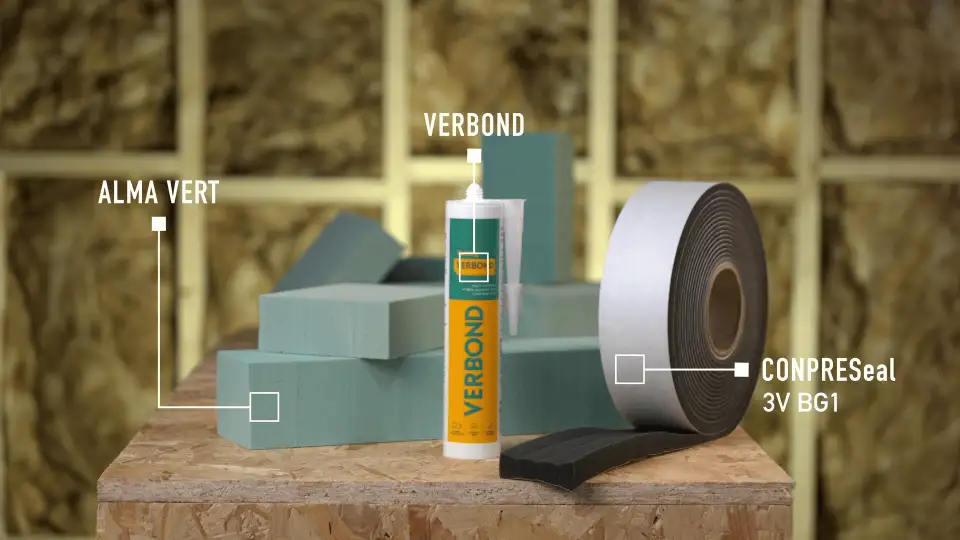

The purpose of Partel's ALMA Vert product line is to break thermal bridges and make thermal-bridge-free detailing easier. Offering builders and designers a highly versatile thermal break, ALMA Vert is available in three density classes: 115 kg/m3, 200 kg/m3 and 300kg/m3. These classes combine excellent mechanical strength, high compressive strength, lightweight composite structure, low water absorption, and extremely low thermal conductivity. The ALMA Vert system also includes two complementarily products: VERBOND hybrid adhesive and CONPRESeal BG1 tape.

The Reimagine Buildings Collective brings together building professionals stepping up to tackle climate change.

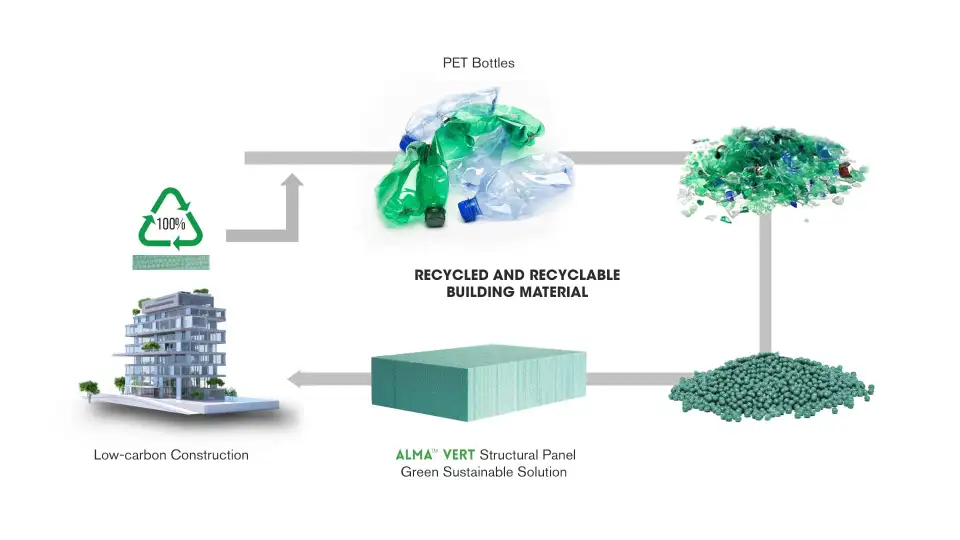

Additionally, Partel’s ALMA Vert meets all conditions to be installed in low-energy building projects, as the product is composed of 100% recycled (and recyclable) material. The core material of ALMA Vert is comprised of recycled PET bottles that can be reused even after the material has completed its useful life. It takes approximately 25 1.5L PET bottles to produce a 4.5-cm-thick board of ALMA Vert measuring 35x35 cm (2x12x12 in).

Consequently, ALMA Vert offers a sustainable alternative to conventional construction materials while providing a lighter, more compact, and breathable component capable of eliminating thermal bridges and ensuring optimizes performance for buildings of any typology.

Key Features:

High-Performance Thermal Break Systems: Specifically engineered to minimize energy loss, ALMA Vert ensures optimal thermal efficiency.

Three Density Options: Choose from 115 kg/m3, 200 kg/m3 or 320kg/m3, tailored to meet diverse construction needs.

Advanced Material Composition: Boasting a lightweight composite structure, high compressive strength, and remarkably low thermal conductivity, ALMA Vert sets a new standard in construction materials.

Low Water Absorption: Ensuring durability and long-term performance.

Ideal for Any Project:

Whether it's a low-energy building project or high-end construction, ALMA Vert is versatile enough to meet and exceed expectations. Its unique properties make it an ideal choice for eliminating thermal bridges and enhancing building performance, regardless of typology.

Learn More:

Ready to be part of the sustainable building revolution? Visit Partel's site for an in-depth look at ALMA Vert, and explore the technical wonders of this innovative product.