In Part 1 of this series from the 475 blog, Brian Hayes of Bellwether Craftsmen Vermont shares his experience and knowledge on how we can address embodied carbon in our own practice.

What is embodied carbon and why does it matter?

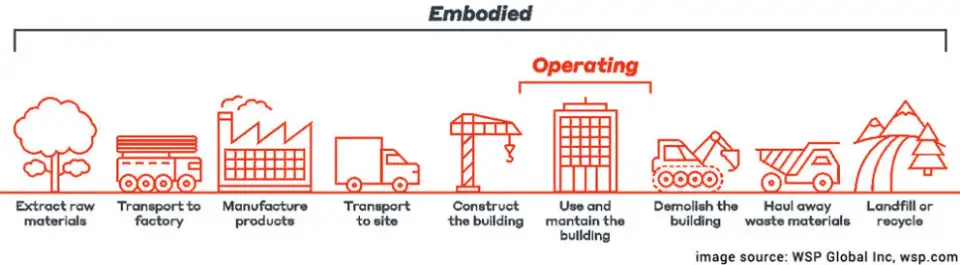

When the building industry talks about carbon emissions, we often think about carbon emissions during the operational use of the building. However, if we want to build sustainably, we have to take embodied carbon into account as well.

The Carbon Leadership Forum defines embodied carbon (EC) in the building industry as “greenhouse gas emissions arising from the manufacturing, transportation, installation, maintenance, and disposal of building materials.” Architecture2030 found that “embodied carbon is responsible [for] 11% of global GHG emissions and 28% of global building sector emissions.”

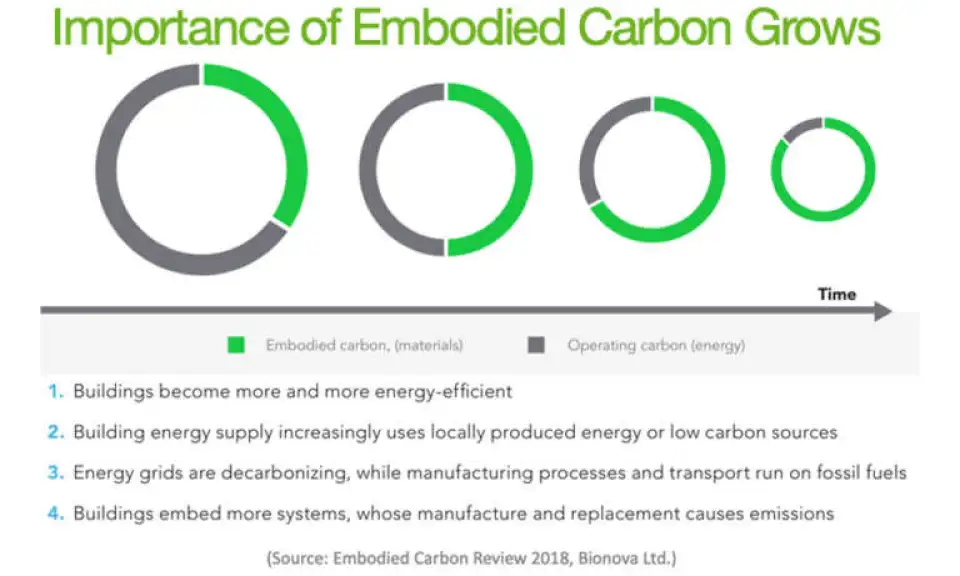

Operational carbon has been decreasing over time with dedicated energy efficiency measures and more low-carbon energy sources on the market. As a result, if left unaddressed, embodied carbon will soon account for the majority of emissions in a building’s life cycle.

Start Now: How To Transition From Business as Usual toward Low-Carbon Construction

Understanding the need to convert embodied carbon awareness & accounting from a concept or ideal to actual practice is critically important. There are simples steps to begin taking now to make a positive impact without actually counting carbon:

Diligently recycle and reduce on-site waste

Replace synthetics with plant-based materials wherever possible

Use FSC wood products

Reduce building size where/when possible

Obtain EPD’s for all project products or request them if they do not exist so we can build that information into our development process