Mike Cairns of Innotech Windows + Doors took us into the weeds of building science last week with respect to the physics of high-performance windows systems. Mike is a Business Development Manager with Innotech and a certified Passive House tradesperson with three decades of construction and fenestration experience under his belt who is equally comfortable at the drafting board or out in the field working with project teams to ensure windows and doors are installed to exceed performance requirements.

Triple-Pane Windows: A Look Beyond U-Values

He also turns out to be nimble and thoughtful guide who, in the above video, effortlessly weaves through the complexities of U-values, heat gain coefficients, and environmental product declarations. Mike also dispels several myths about high-performance windows and reexamines the belief that triple-pane fenestration systems are always the best option for high-performance buildings. He makes a convincing case that there are a number of factors that can influence enclosure performance and project goals that need to be considered.

Moving Beyond U-Values

For a lot of people, there are only two things that matter when it comes to windows: U-values and solar heat gain. However, as Mike explains, the fixation on these two metrics fails to appreciate a lot of the nuance. “In the quest for low U-values, have we lost sight of what they mean, how they're calculated, and their importance when evaluating and specifying windows and doors for high-performance projects?” he asks.

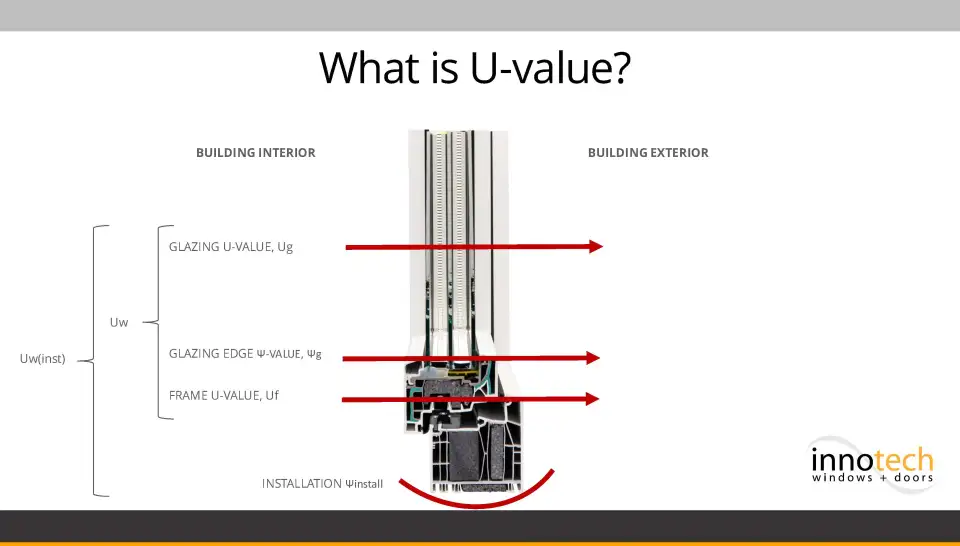

While U-values are measurements of how well a component prevents the transfer of heat, and that a lower value means less heat transfer and less thermal loss (both very good things), that’s not the whole story. In the video, Mike starts by noting that U-values for windows can be broken down into more specific values, as shown in Figure 1. These values include just the glazing (Ug), the whole window (Uw), and the whole window once installed (Uw,inst). The latter can be especially important in any type of construction, since a bad installation can dramatically hurt thermal performance and create thermal bridges, leading to problems with condensation and mold.

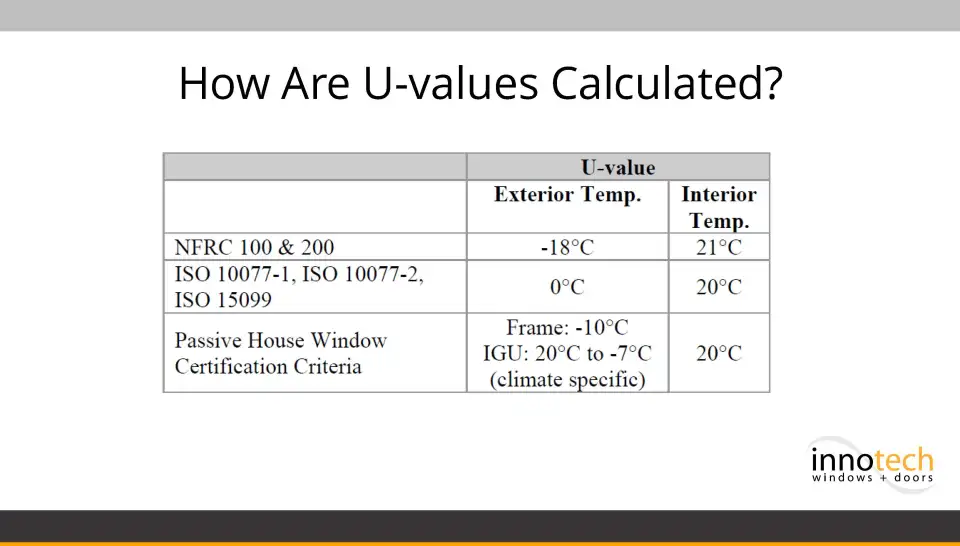

Mike then describes how U-values are calculated for Passive House certification and by both the National Fenestration Rating Council (NFRC) and the International Organization of Standardization (ISO), as shown in Figure 2. For those who want to know how the proverbial sausage gets made and how the U-values that appear on spec sheets are determined, it’s an engrossing journey.

Like U-values, solar heat gain values are not universal and there are different ways to calculate them. As Mike notes, the NFRC will evaluate the whole window, ISO can evaluate the whole window or just the center of the glass, and the Passive House Institute (PHI) only evaluates solar heat gain values as measured at the center of the glass. As a result, windows with smaller frames and higher glass-to-frame ratios will look like they perform better in NFRC, even if these frames, and the window assembly as a whole, may have worse thermal performance.

“NFRC is intended to provide a direct comparison between windows at a standard size,” Mike says. It's not a specific product performance for projects. PHI methodology is specifically designed to provide specific heat flows for products at actual size and for specific projects.”

Perhaps a bit more controversially, Mike also shows that a lot of factors go into determining a window’s performance, and that the notion that a triple-pane model is always better than a double-pane one is simply not accurate. Low-E coatings, the amount of space between panes, and the thickness of the glazing itself can all be factors that affect performance. Moreover, there is no one-size-fits-all solution for all building types and all climates when it comes to choosing a window.

Beyond performance, there are other criteria that one can consider when making a choice about windows, including: airtightness, embodied carbon, and affordability.

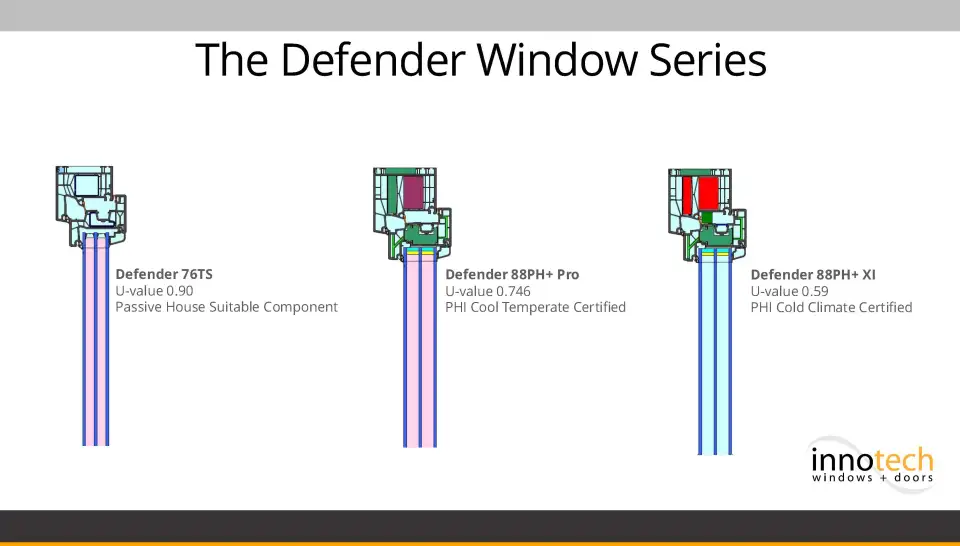

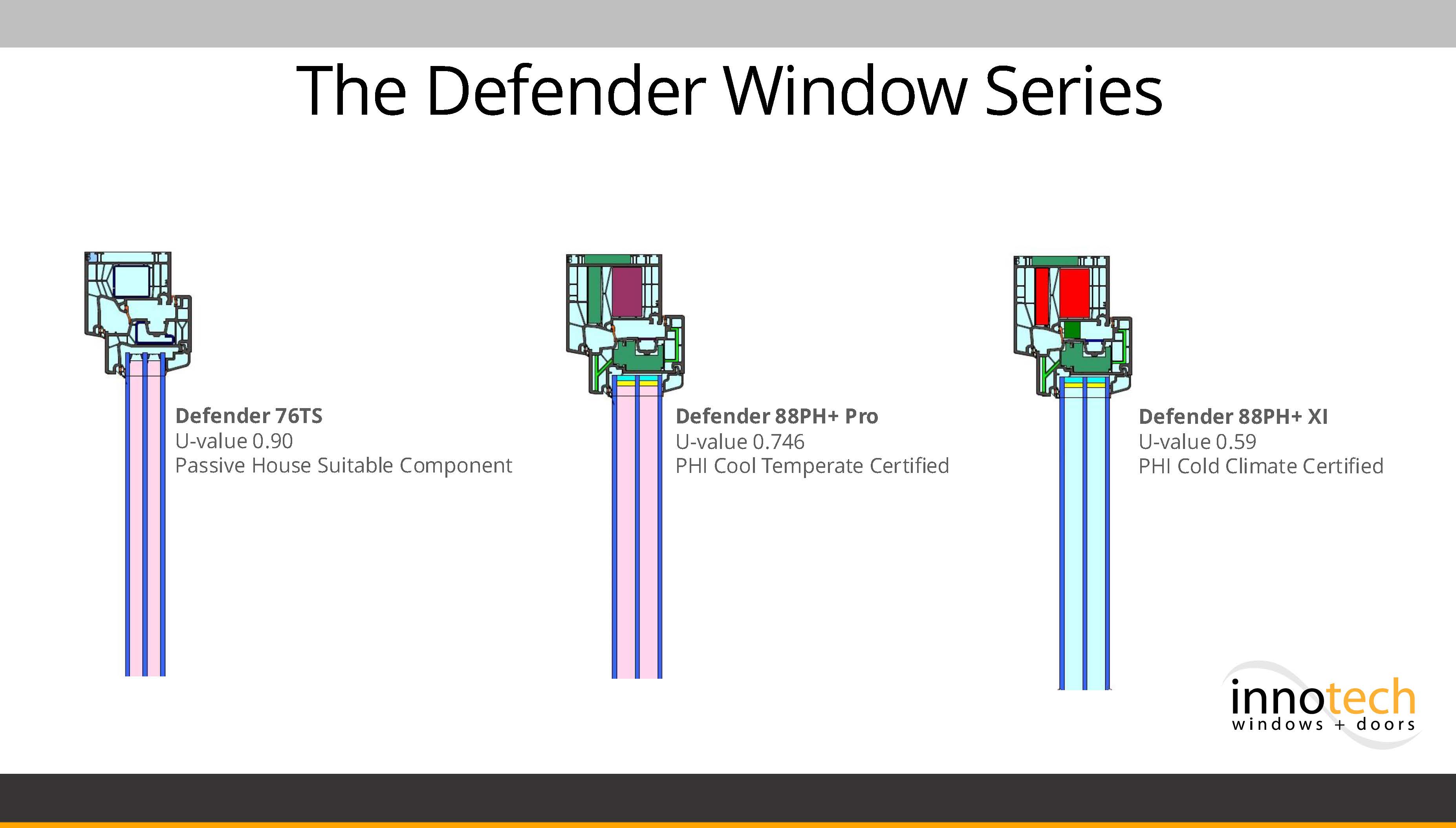

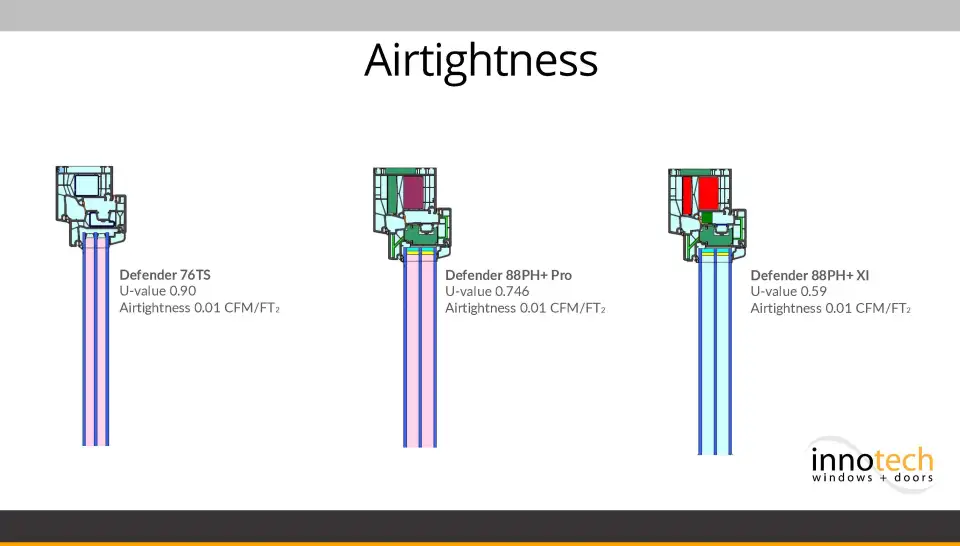

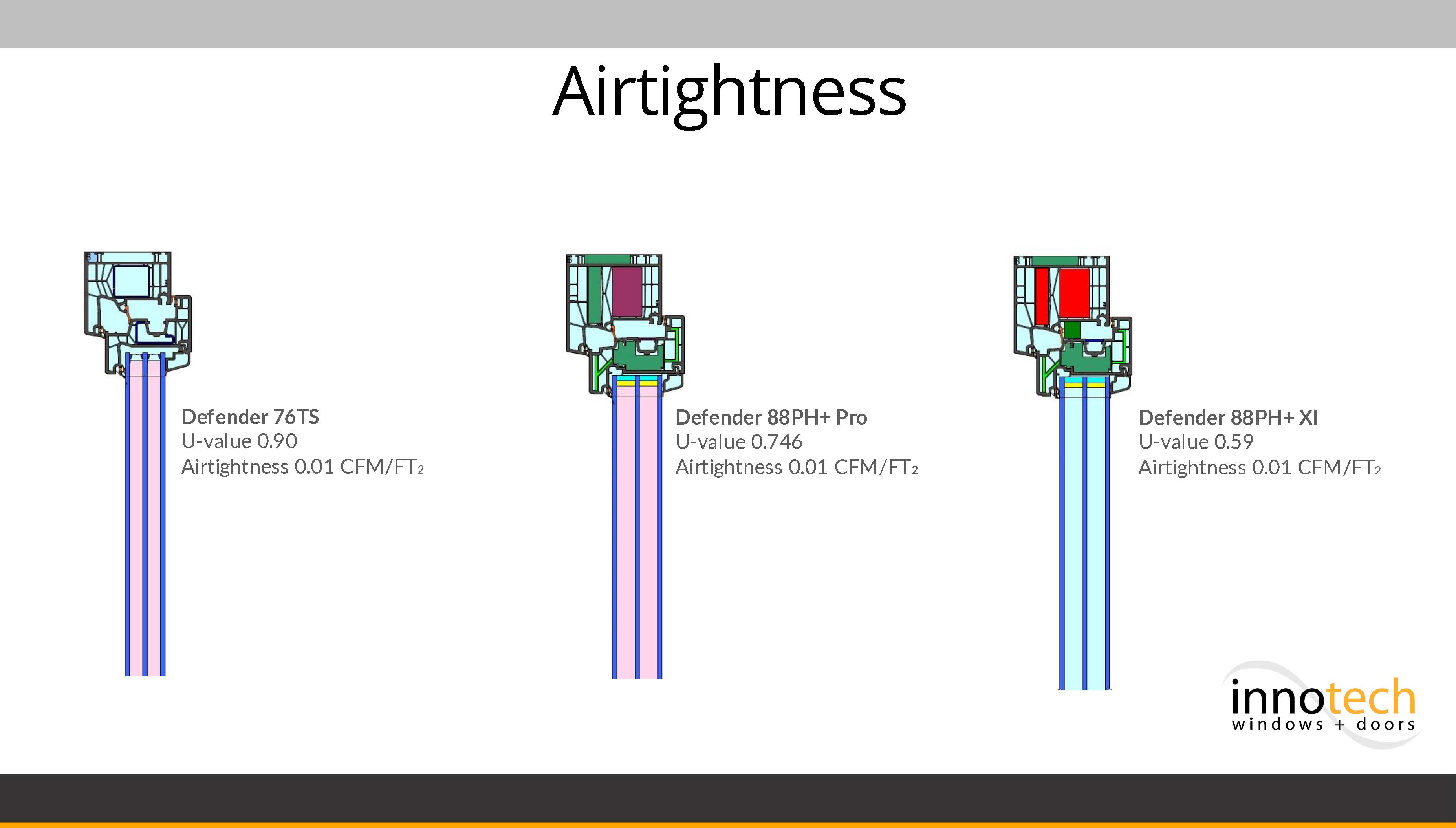

Figures 3 & 4. While the Defender window series has a range of U-values...

All three models have the same exceptional airtightness scores.

With respect to airtightness, it is entirely possible for a window unit to have a very low U-value as measured in a simulated environment but not be particularly airtight, which can adversely impact the comfort of the home. Additionally, projects aiming for Passive House certification with leaky windows are going to struggle to keep heating demands low and pass their final blower door test. Innotech offers a range of window models with varying U-values, but they all designed and manufactured to provide superior airtightness (see Figures 3 and 4).

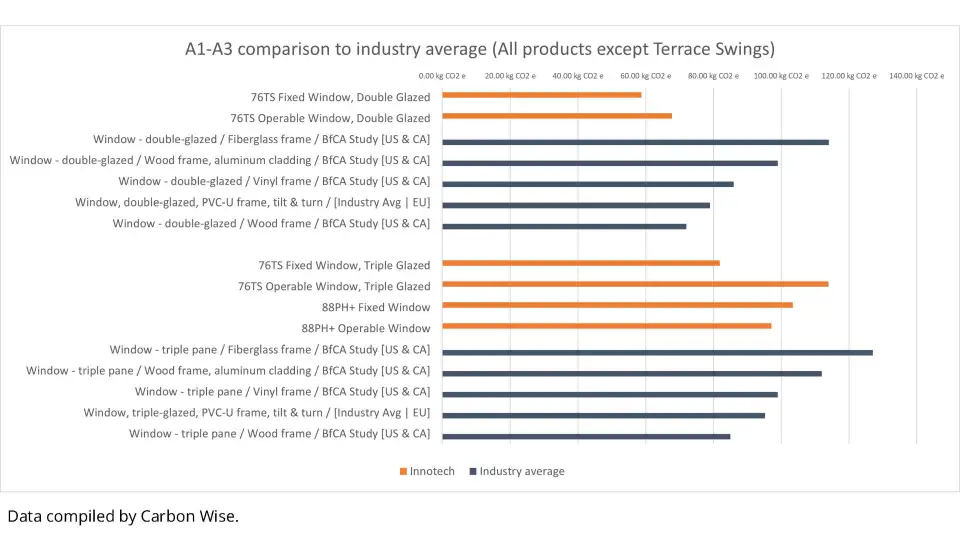

Mike also makes the point that adding an extra pane of glass affects both financial budgets and carbon budgets. While it’s no shock that triple-pane windows typically cost more money than double-pane windows because more raw materials go into creating them, the same is true with respect to the amount of embodied carbon within the window units. In fact, the difference between a double-pane window and a triple-pane window can be significant, as shown in Figure 5. While Innotech strives to minimize embodied carbon, the manufacture and transportation of triple-pane windows is necessarily resource-intensive. If the performance of a triple-pane window is only incrementally better than a double-pane window, one has to ask if that improvement is worth the money and the carbon.

This only scratches the surface of Mike’s talk from last week’s Component Spotlight. To hear more about how to balance performance, cost, and upfront carbon budgets, as well as the Q&A session that followed the presentation, check out the video at the top of the page. You can also learn more about Innotech by checking out their site here. Watch the video here.

Top Project: Kees & Claire Hut in Whistler, British Columbia. Photography by Martin Knowles.