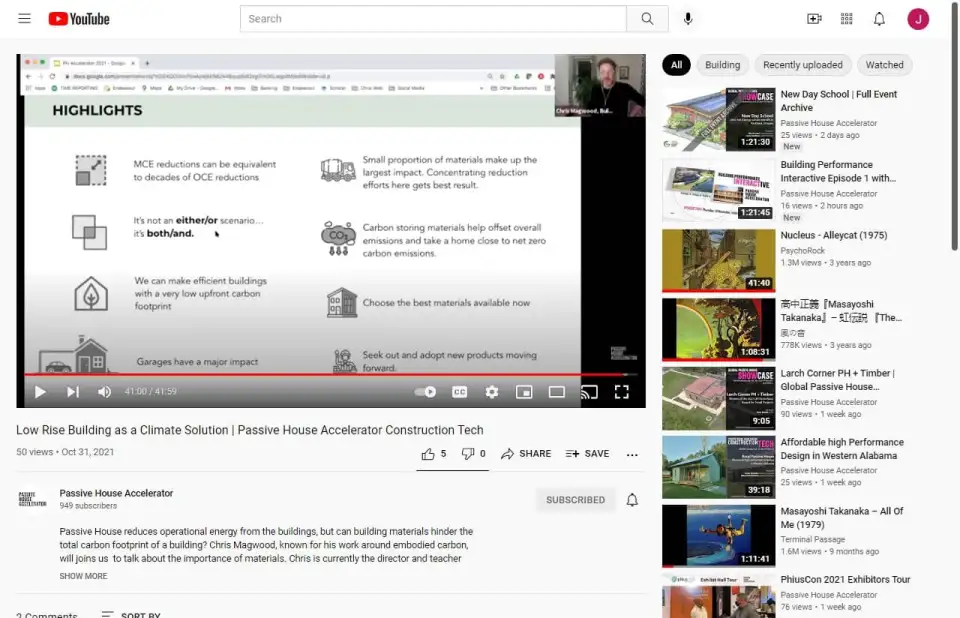

Passive House reduces operational energy from the buildings, but can building materials hinder the total carbon footprint of a building? Chris Magwood, known for his work around embodied carbon, joins us in the video to talk about the importance of materials. Chris is currently the director and teacher for the Endeavour Centre in Canada, as well as a designer and consultant with over 15 years of experience. During his presentation, Chris explores how the materials, strategies, tools, and costs for making real zero carbon buildings focusing on low-rise construction as a carbon reduction tool. View the chat transcript.

Full Transcript:

Chris Magwood:

I'm really excited to talk to this group. I love what is happening at Passive House Accelerator and I'm really excited to be able to bring this piece to what everybody is trying to do, which is figure out buildings and climate and what we do and how we go forward to keep building amazing buildings for people who need them and not wrecking the planet as we do that and maybe even helping rescue it a little bit. I warned people who came on it earlier: You're getting a bit of a Frankenstein presentation in that I've patched pieces of different presentations together. I feel like this group has a very specific already established knowledge base and some interests that are unique. All the information is here. You'll just see the format change maybe sometimes between slides, but hopefully everything is here in a logical order that you're able to follow and looking forward to a discussion at the end too.

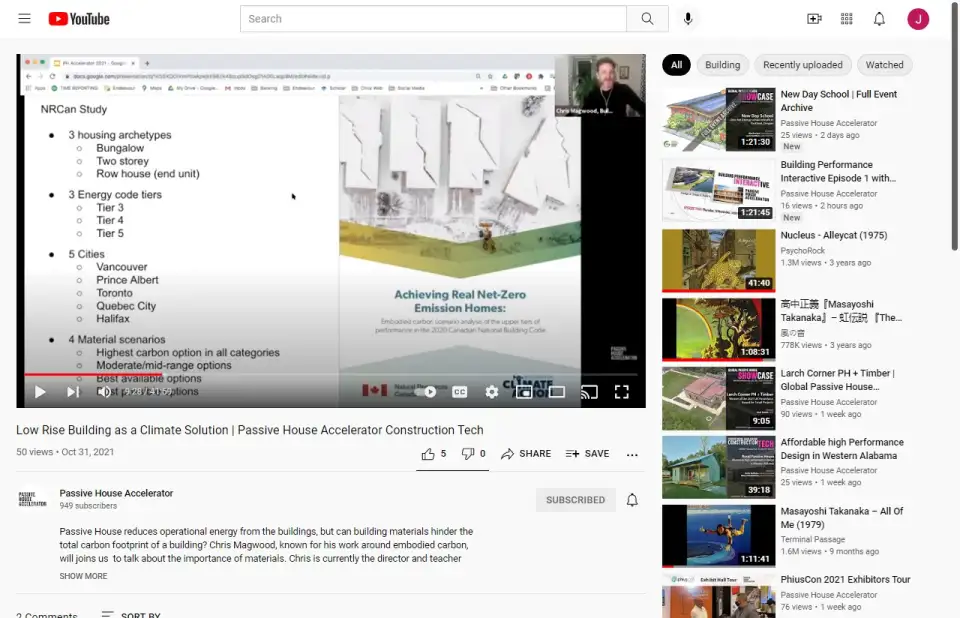

So one of the bases for this presentation is this report that I just helped author with Builders For Climate Action and Natural Resources Canada, which is the branch of the Canadian Federal Government responsible for home energy efficiency and all the programs that the federal government offers. We did this study, "Achieving Real Net-Zero Emission Homes" and it was the first time that a national government had really taken a dive into material emissions and tried to see what they mean for the country. It's the beginning steps of trying to figure out how this might fit into the regulatory world, so I was really excited to be part of it. But you'll see part way through this we also segue into a bit of a presentation. We've been helping the cities of Nelson and Castlegar, B.C., also study this for their region and they're actually going to be instituting some incentive programs, so those two bits of working are coming together in this presentation.

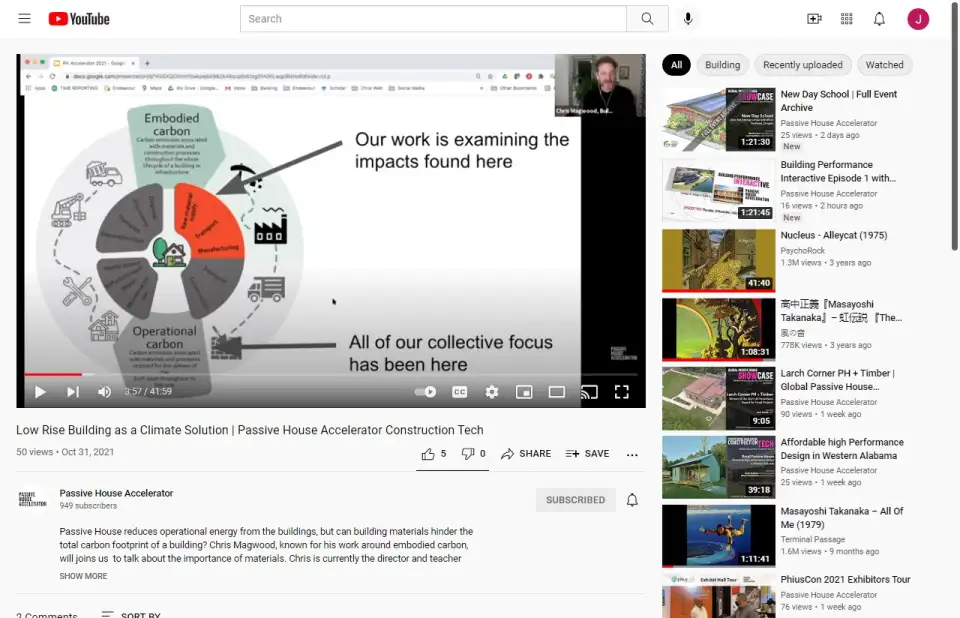

So very brief background, because I think everybody knows the story by now, but all of us have been working super hard at figuring out how to eliminate or greatly reduce at least, the operational emissions that come from buildings. Such an incredible focus over the last 20 years. If we really think back, when I built my first house, my building inspector laughed at me for wanting to put more than R-12 in my walls. He just thought that was the most ridiculous thing he'd ever heard. Why would anybody do that willing? So we've come a long way from then until now and we've all done really great work to really address that side of the emissions puzzle.

But what I've been looking at recently, and honestly my own dive into this came from 10 years ago, I wanted to know what the carbon footprint of the building that we were working on at the endeavor center that year might be, out of interest ("Hey, what does this look like?"). And that started me down this sort of 10 year rabbit hole of trying to figure that out, mostly because when I first started I couldn't figure it out because nobody seemed to know, and then my interest happened at the time that a lot of people got interested. So a really interesting body of knowledge has grown in that past decade.

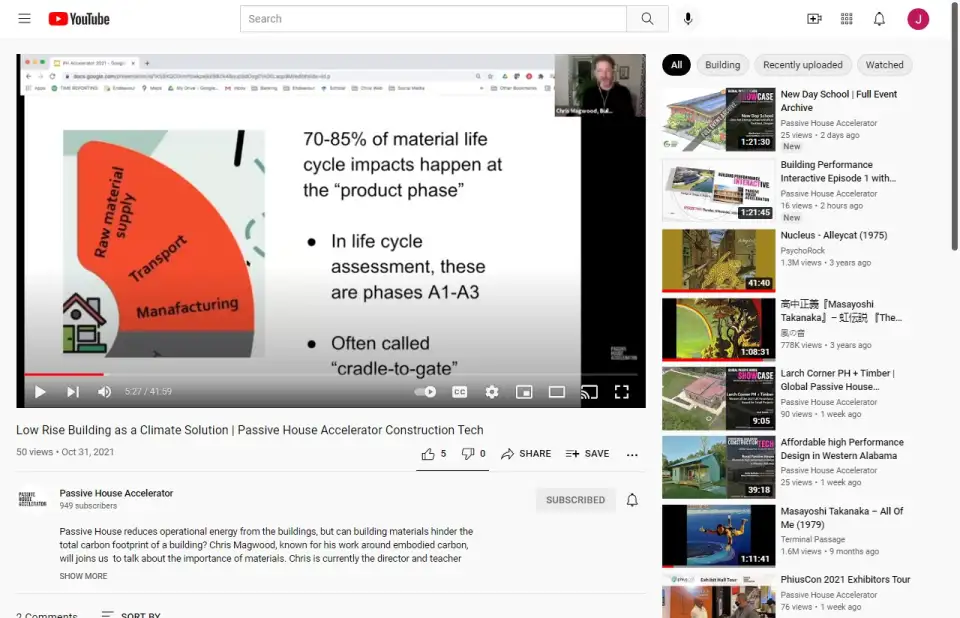

But the specific thing I want to talk about is the sort of material emissions, this red highlighted bit in a life cycle of a building and it's materials. And the reason that I want to focus there is that, that product phase people often call cradle-to-gate is where the majority of the emissions from all the materials that we use in buildings happen to occur. It depends on the material, but somewhere between sort of 70 to 85% of the emissions that are going to happen over the entire lifecycle of a product. So from its initial raw material harvesting to when it finally is taken out of the building and incinerated or land filled or whatever happens to it at the end of its life almost everything happens up front here. So, when we're thinking about addressing the climate, today's emissions matter a lot and here's where most of them lie and this is where we can dive in and really address these. The other phases, in particular, transportation to the construction site and construction site emissions tend to be between 5% and 10% of the total lifecycle, so it's not as big as most people think, but not insubstantial either. It's hard to address that broadly because where you are, where materials are coming from, how you're getting them to the site, what kind of energy you're using on the site; all of those things are very particular and unique, whereas the material emissions most of these things are built in factories and it's very easy to assess what's going on in that factory and so we know that the emissions we're recording and understanding here are quite rigorous and understandable.

And so we get the data that's sort of driving these studies from these documents called Environmental Product Declarations or EPDs. And that's an internationally standardized way of reporting on a bunch of different environmental impacts from in this case building materials, but the methodology is actually used for all kinds of products. So each product has a category that it falls into, so you don't necessarily use the same rules for say farming lumber as you do for flooring. So within each broader category there's a set of rules. But basically an EPD, makes sure that everybody's counting the same kinds of things in the same way according to the same methodology. So we get a pretty comparable look between products in the same category. And so I take the global warming potential that they report in an EPD and figure out what that means for the amount of material in a particular building.

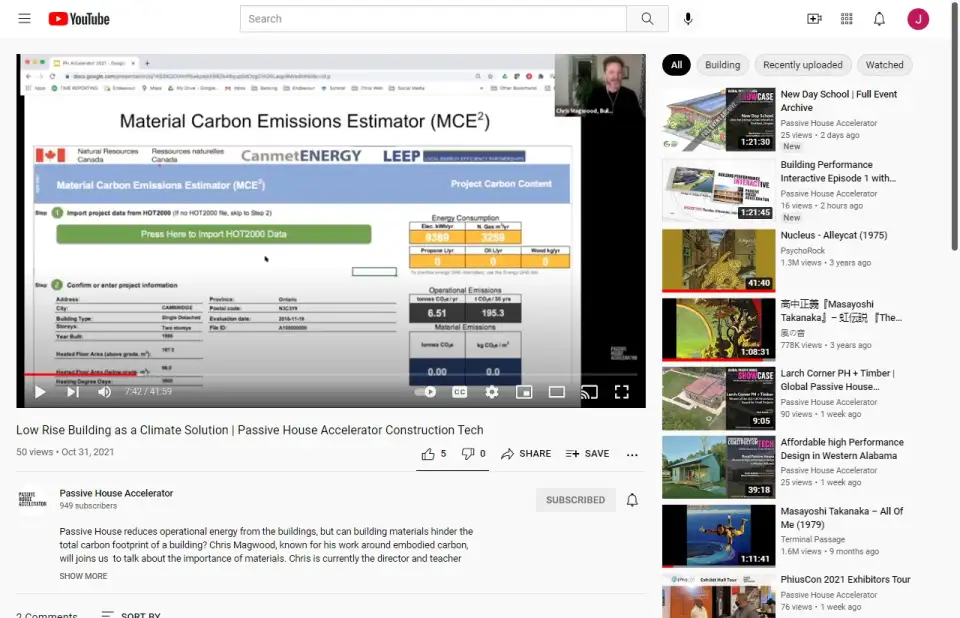

And first for my own purposes, I started to build out a spreadsheet of all of these EPDs, and wanting to model my own buildings and some research buildings I was doing. I built a sort of half-ass spreadsheet, that gave me the answer but that if anybody else looked at it, they wouldn't have known what's going on, but that has been refined over time. We built a version of it for Natural Resources Canada, which they called it MCE squared tool. We also have a version of it called BEAM, both of them are going to out in public before the end of this year, so excited to have that tool get out into the public.

Essentially each tab on the spreadsheet is a different part of the building. This is a snapshot for the exterior walls where we've told the software how much wall area we have. We've given it an R value. And what I really like about how we built the tool out is that right away you see a comparison for the building you're working on of the carbon footprint of all the different materials. So I can see, oh, fiberglass would give me this in this building, blown in fiberglass that, narrow wall this, cellulous that. It's this really great sort of tool where you get to compare the actual results for your building so you can decide on making material decisions and material swaps here by seeing the carbon footprint in real time.

That tool is behind this NRCan study that we just did, and the study isn't based on real homes; it's based on archetypes. So NRCan has a bungalow, a two-story and a row house that they have plans for that they used as a typical single family homes in the country. They gave us HOT2000 energy models for these archetypes at tiers three, four, and five of the national building code, five being the most energy efficient. It's like the net-zero ready version of the code. And they gave us models for five cities across the country: Vancouver; Prince Albert, Saskatchewan; Toronto; Quebec City; and Halifax, Nova Scotia. We then built up four material scenarios for each of those models. One where we picked the highest carbon option in every material category. One where we picked pretty typical selections from the mid-range of the options that are available. One that we picked what's the best material, in other words has the lowest carbon foot print, but it is widely available and code compliant across the country. And then a final model where we just picked the best option, whether it was a typical material or code approved or not. We're sort of bookending the study with a worse case and a best case scenario and then showing a bit of what's possible in the middle.

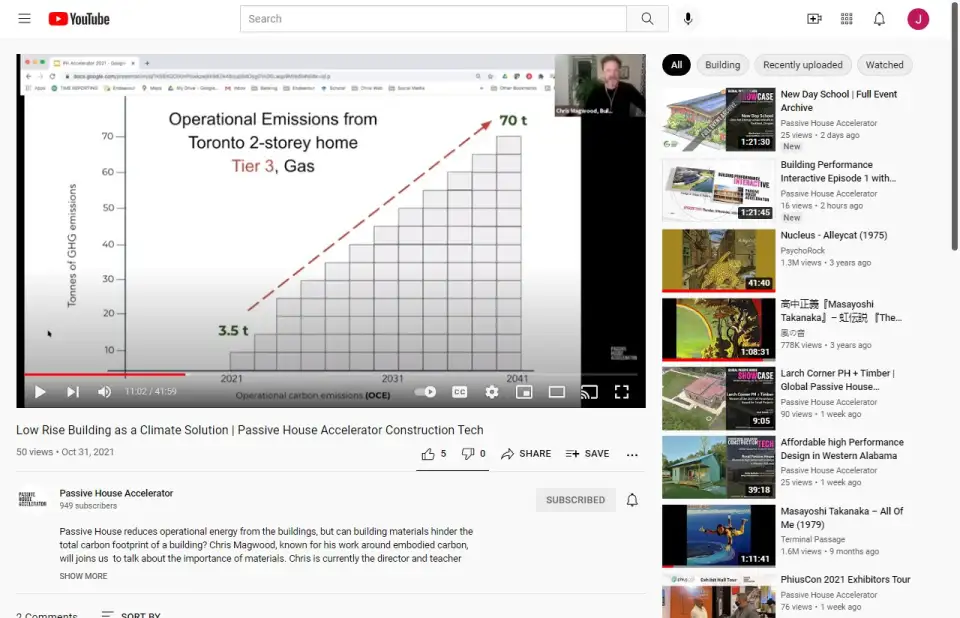

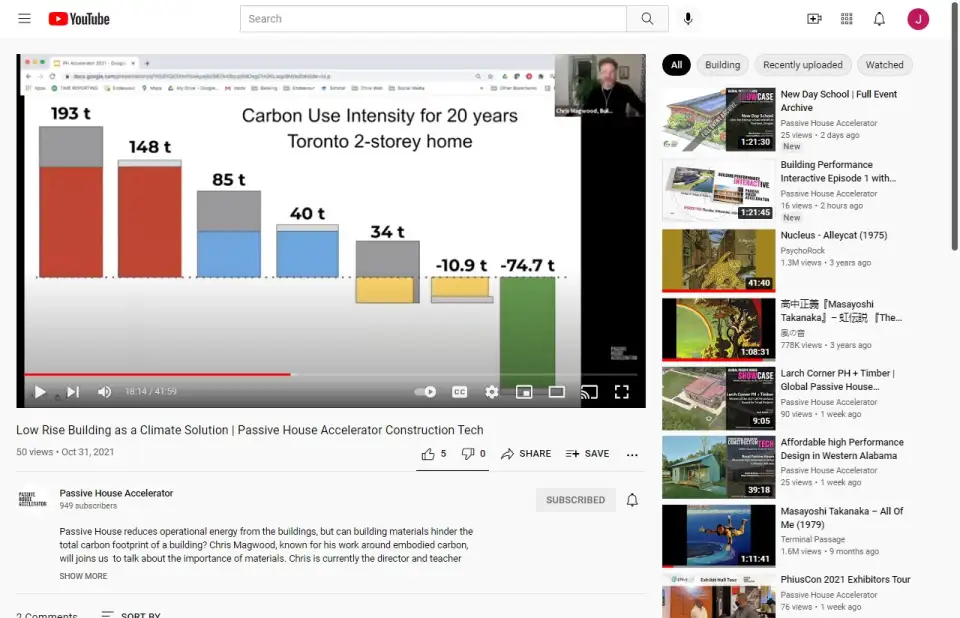

So this part you're all going to get how this part works. So I'm looking at the two story house from Toronto here, but things mapped out pretty similarly across all of them. So tier three is our building code norm right now, so it's a code compliant home build today heated and the hot water done by gas, and that building from the HOT2000 model has about three and a half tons of emissions per year--or I just extended that over 20 years, so 70 tons over 20 years and that's probably about what you would all expect from something in this climate.

If we bump that house up to tier four and it's still on gas, it's great. We drop 20 tons of emissions over those 20 years. It's down to 2.7 per year, so clearly moving buildings along the energy tiers does what you would expect it to do.

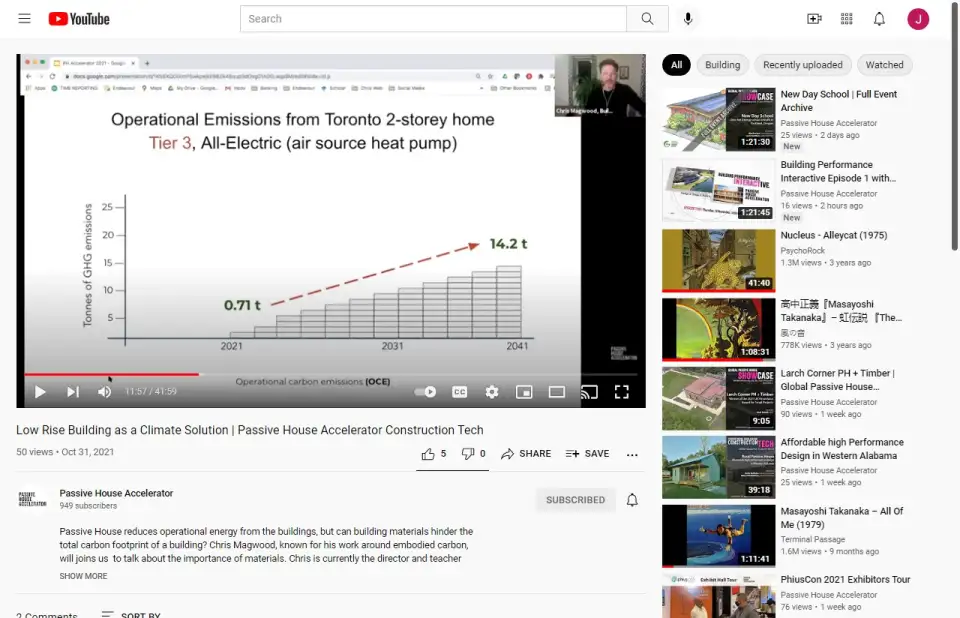

The tier three model, if we change it to all electric, so an air source heat pump was doing the home heating and an electric resistance heater for the hot water tank. Even at tier three, the operational emissions have dropped to under a ton per year (14 tons for the 20 years). So obviously you can see there's a big difference between using a fossil fuel and using relatively clean electricity here in Ontario.

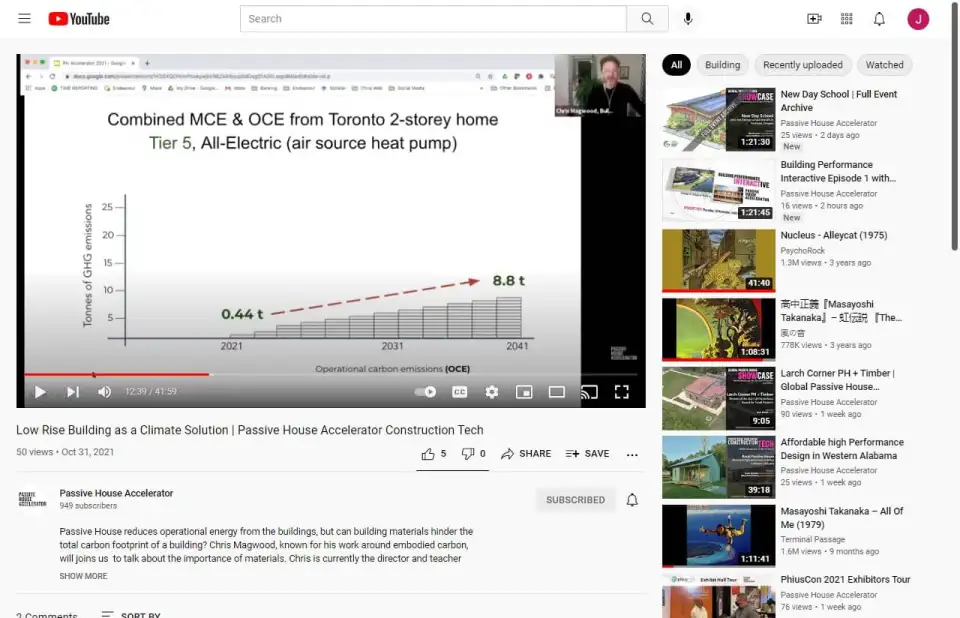

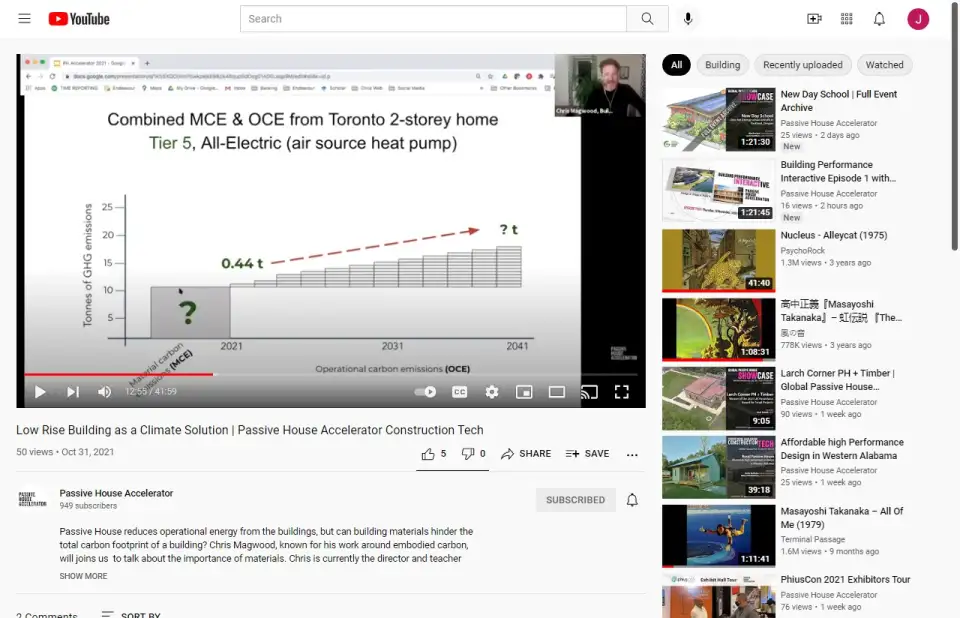

If we bump that electric house along to tier five, we've got it down to under half a ton per year, just under nine tons for the 20 years. So all of that is not news to you. You all know that that's how things go.

What we're trying to provide them in this study is, what is this end number after 20 years if we add the materials to it? Is this operational side, is it the only carbon footprint that building's going to have, it's materials also have lungs? And we don't know that answer until we know this answer.

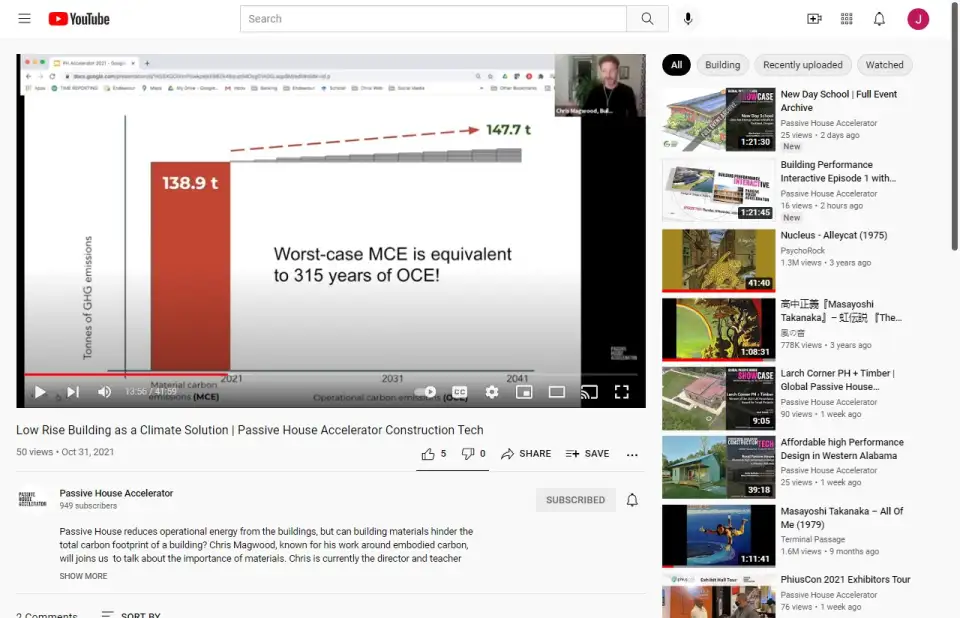

So, in the study, this is what we've found. If we picked the worst materials in their category and these are not uncommon materials, this includes things like brick cladding, it includes things like XPS insulation under the slab and around the basement, spray foam insulation in the walls. They're not unusual materials, it's this model's maybe unusual in that we put them all in one building. But you can see what happens that the carbon footprint of just the materials absolutely dwarfs the operational admissions. So the vast majority of the emissions lie here. The material emissions for this one are equivalent to 315 years of operating emissions. If we're going to make a difference in this building, we're going to make the difference in the materials and not anymore in the operations side.

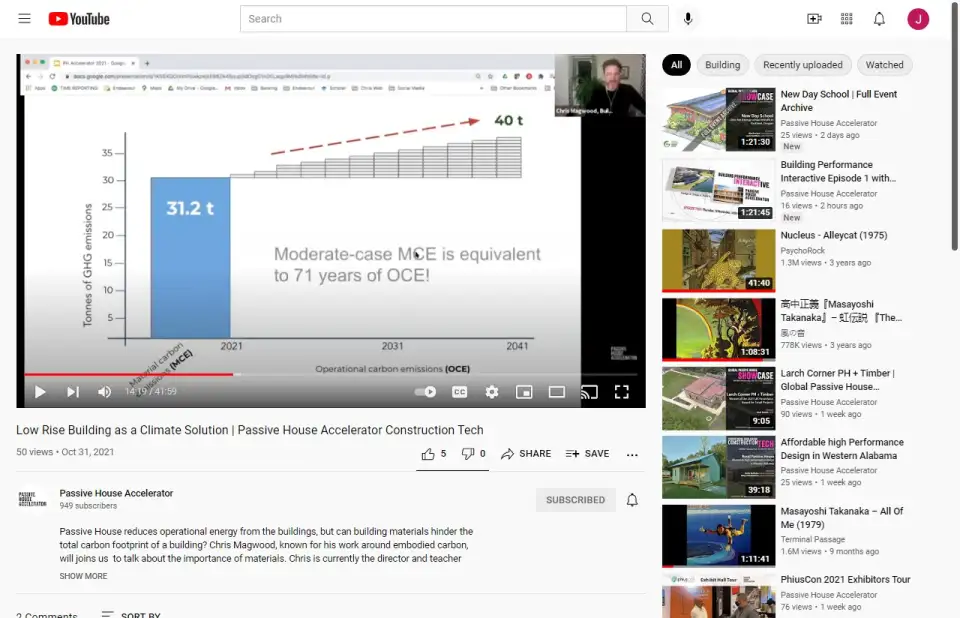

Here, you'll notice that that scale has changed a bit. We had to adjust it to fit that last model. A more moderate materials example is 31 tons of material emissions, taking the building 40 tons over the 20 years. So this is a much lower material emission than the other one by a substantial amount, but it's still equivalent to over 70 years of operating emissions. So again, even when we get into a more sort of moderate material pallet, the materials are still the dominant part of the emissions profile well past when we have to care about things for the climate. 70 years is not the time when you want to start seeing paybacks on carbon footprints, so the moderate version still leaves a lot to be desired in terms of meeting climate goals.

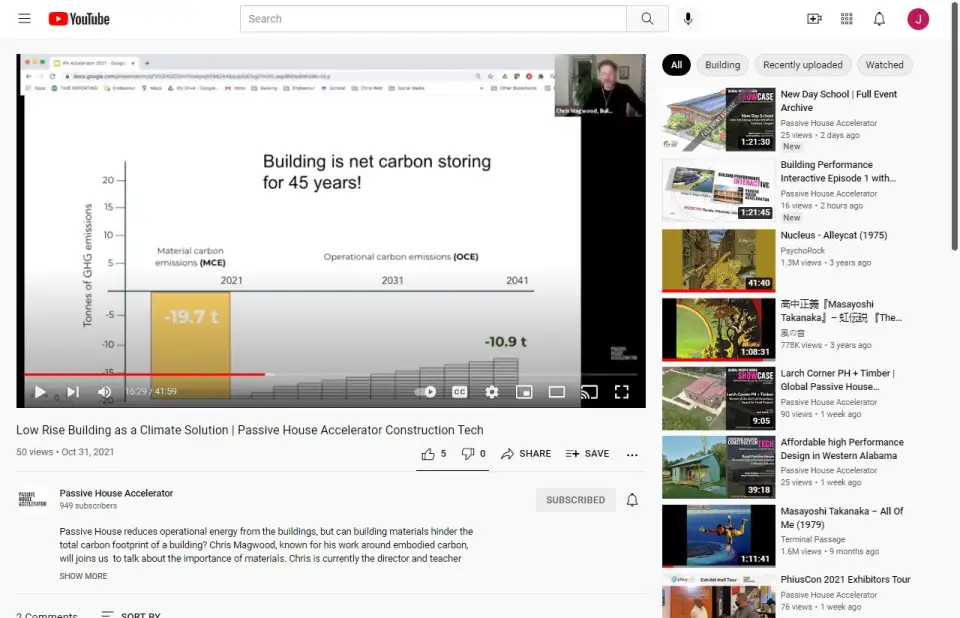

The third model starts to look different and quite positive. This is the first model in the study that has a net carbon storage and this was achieved pretty simply. The main things that we changed in this model were the cavity and the roof insulation were cellulose. The exterior continuous insulation was wood fiber board. And the concrete was the best mix that we could specify for the Toronto region, for this project. Pretty much that's the deal that pushes this model from having a pretty substantial carbon footprint to being a net carbon storer. And so you can see what happens if we start the building in a position of net carbon storage with a minus number; it operates for 20 years and it's still a net storer of carbon. That was the reason we titled the report "Achieving Real Net-Zero Carbon Buildings," it's because it's only a net-zero carbon building if when you add both of these things up together the materials and the operation, it's net-zero. So if we can get there, then that's where we need to be and this is a pretty achievable model of a residential building to be able to get there. So that's going to extend out for 45 years. So this building won't have a net carbon footprint for the next 45 years, which is pretty much what we need to do and it's pretty great to see that it is doable. Again, this model and all materials that you can go get your hands on and use pretty easily today.

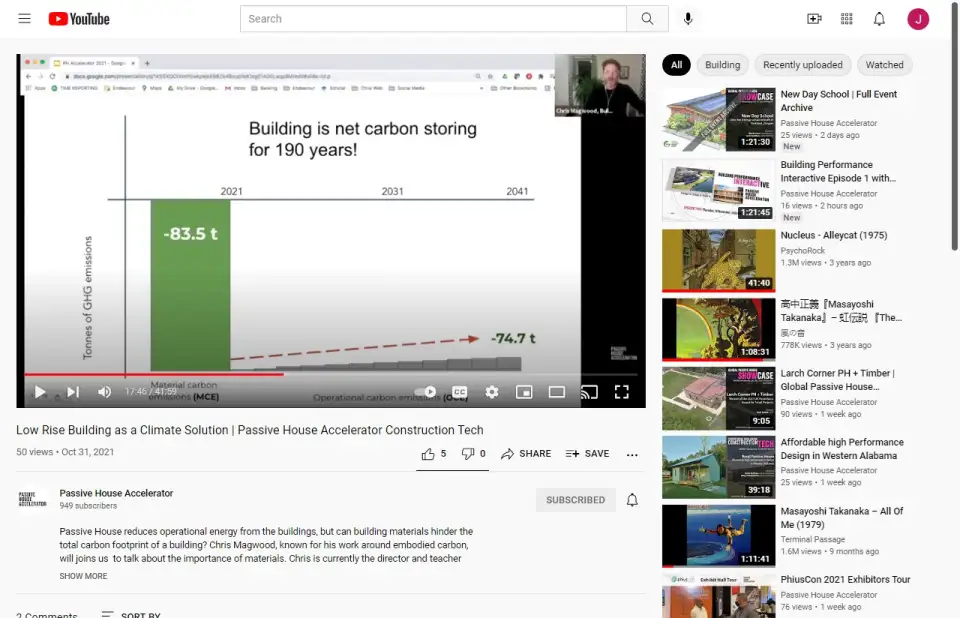

This is sort of the more ambitious model. This is using materials that maybe aren't so common. We know that they're doable, because that's what I do in my day job is make buildings like this. So this has things like straw bale walls instead of cellulous walls. It has a pressure treated wood foundation. It has things like linoleum and cork flooring in it. We threw as much carbon storing material as we could at this building, and you can see what happens here is the amount of carbon storage is actually really substantial. A building like this actually starts to be a noticeable reverser of climate change and not just a zero. This building is going to stay net carbon storage for almost 200 years. That's well past my life, my daughter's life and whatever children she has, their life, and maybe beyond that, too. So I think if we want to be building in a way that we can really look to future generations and say, "Yep, we did what we could to help you have a climate that you can live with." This is where we need to be, to be aiming our practice.

This is just those models put together so you can see the extent of the impact. Essentially, we built the exact same home. It's got the same number of rooms, the same level of energy efficiency, the same number of doors and windows that help functionally and operationally the same building, but its carbon footprint can fit anywhere in this really, really wide range. I think there's a way to sort of look at this as a series of steps. If I'm here, then I need to get here, and then here, and then here, and then here, and then here. We don't have to just all get to the green right away. There's a way to sort of progress ourselves there that each one of these steps is really substantial. This blue model is less than half the carbon footprint of the red. And the yellow is less than half of the green, et cetera. These are big steps. We could break them up into smaller steps as well. Figuring out where you are in that progression and then figuring out just how to get yourself to the next step first, and then the next step is a pretty good way to look at that.

I'm going to switch up a little bit and just talk about that carbon storage in buildings, because sometimes it took me a while to wrap my head around that and I know that, that happens a lot for people hearing this for the first time. So the way all of the materials that in this study that had carbon storage are plant-based materials. There also can be carbon storage in minerals, but none of that technology is really at hand right now. Hopefully, it will become soon: things like concrete aggregate, gravel made from CO2 that pulled out of the smoke stacks of cement factories. Things like that are happening now and starting to be scaled up, but right now if we want to put captured carbon dioxide it's going to be plant based.

So plants absorb CO2 as they grow, that's what they do. The C stays in the pant, the carbon becomes part of the body of the plant, and the oxygen comes back out for us to breathe, which is a really great byproduct. Literally billions and billions of tons of carbon come out of the atmosphere this way. Just grain straw alone is four billion tons of captured carbon dioxide annually. That's the emissions of India. They're the fourth biggest emitter on the planet. It's completely taken out of the atmosphere just by grain straw every year. But then we burn that grain straw or we let it rot or in some way that carbon goes back to the atmosphere and we lose it again.

The CO2 is pulled down by the plants and we interrupt it by putting it in a building for some chunk of time. Hopefully a decent length of time, like 60 to 200 years, and maybe then it will come out, but maybe then we'll have the climate under control. We won't be burning fossil fuels like crazy, or we'll be smart about carbon and people will do appropriate things with it when it does come out. But the idea is we're sort of interrupting that carbon flow. We're taking carbon that would have gone back to the atmosphere and sticking in buildings for a long time so that it doesn't end up back there.

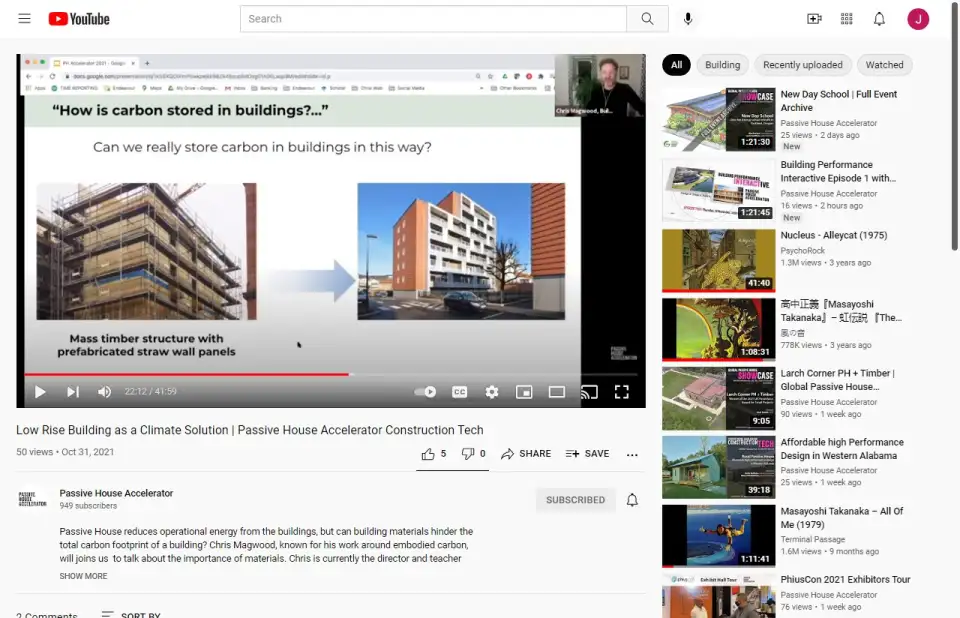

And you may be wondering, that's a weird building choice, Chris Magwood. Why did you put the picture of that building here to talk about carbon storage? And I picked that one especially because it's a very large straw bale building. It's a seven story apartment building in France. It's mass timber frame, pre-fab straw bale wall panel enclosure around the outside. It's Probably the biggest carbon storing building on the planet. Pretty cool. We can do this right now today. This thing has a monstrous amount of carbon storage in it and it's things like this we're going to have to do if we really want to drive towards that best case green building model.

Some places that we've done it, that store carbon, there's a little straw bale residence. There's a hempcrete and hemp batt institutional building at Trent University. There's a very large straw bale school also in France. So we're not pipe dreaming here that this is possible. And I'm sort of using some straw examples here because that's the world that I'm from, but people are doing this with bamboo. People are doing it with rice hulls. People are doing it with agricultural residues of all kinds. So these are the kinds of buildings that would exemplify that green typology of net carbon storage.

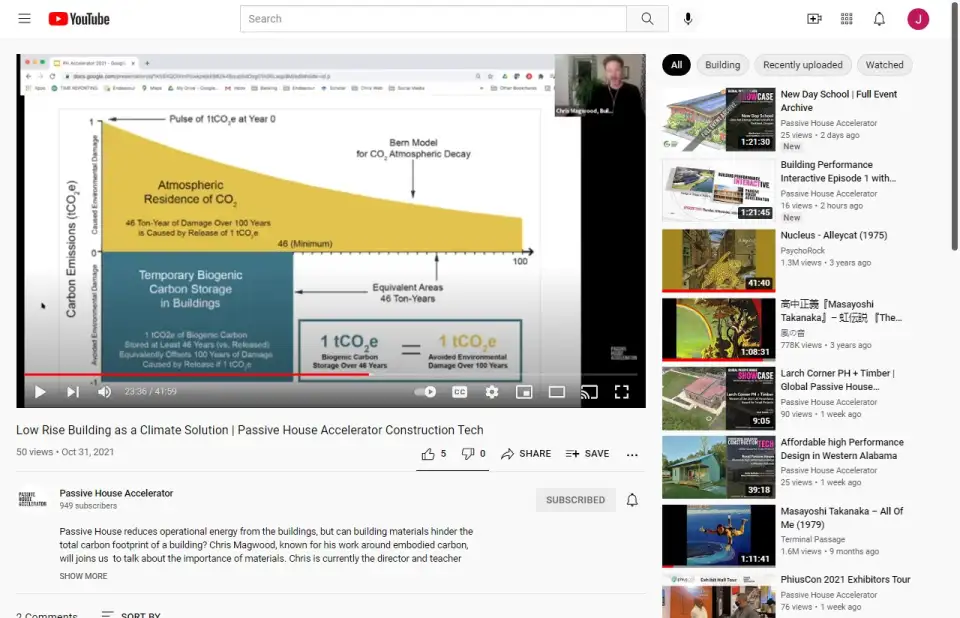

Because you're a technical bunch, I thought I would sort of get into the technicalities of carbon storage. This has been an interesting ride for me. I'm not climate scientist. I'm not really a scientist of any kind; I'm a builder. So wrapping my head, I can get that okay, carbon comes from the atmosphere, it goes in the plant, stays in the building. Okay, great. But what does that actually mean for the climate? Luckily climate scientists have thought about this and they know this and they've figured this out. So what this is showing is the yellow part if starting with one ton of carbon emissions. So if today one of us emitted a ton of carbon, we drove our car for a few miles, poof, there's a ton of CO2 in the atmosphere, that stays in the atmosphere. It decays slowly over time. This ends at 100 years. It continues to have an effect on the climate beyond 100 years.

But over 100 years, that pulse of carbon dioxide is said to do 46 ton years of damage to the climate. I don't actually know what a ton year of damage to climate looks like, but that's sort of how it's mathematically created. So on the flip side, down here is a ton of carbon that we store. So in our building, in this cellulous insulation of your building you put a ton of carbon. If that carbon stays in that building for 46 years, it has done the opposite of 46 ton years of damage. It's relieved the atmosphere of 46 ton years of damage. So in other words, when the green square has the same area as the yellow area, then we've fully offset a ton of carbon. So anything that we're going to put in the building, that's going to last 40 to 50 years; things like the insulation, things like the framing, the sort of main parts of the building that we're not going to change out, then that's how we can sort out the climate science justification for that being a meaningful amount of carbon storage.

What does that mean? Everybody's always like, "Yeah, but when the carbon comes out of the building, doesn't it just go back to the atmosphere?" Yes, it does, but in the 50 years that it's been in the building, it has done the work of taking a ton of carbon out of the atmosphere. At that point, it's basically it's a new emission, and obviously we don't want to burden future generations with lots of new emissions, but at a time right now, when we're still burning fossil fuels uncontrollably, giving ourselves this 50-, 80-, whatever it is, 100-year window of removing carbon from the atmosphere, is one of the few options that we have to stop the runaway freight train. If we figure out how to stop that runaway freight train we'll probably have figured out better things to do with carbon when they come out of buildings than burning it. So this is sort of when I talk about carbon storage in buildings, that's what I mean. The stuff that's going to hang out in a building for, 46 seems to be the magic number, but you can call it 40 or 50 or somewhere in that range years.

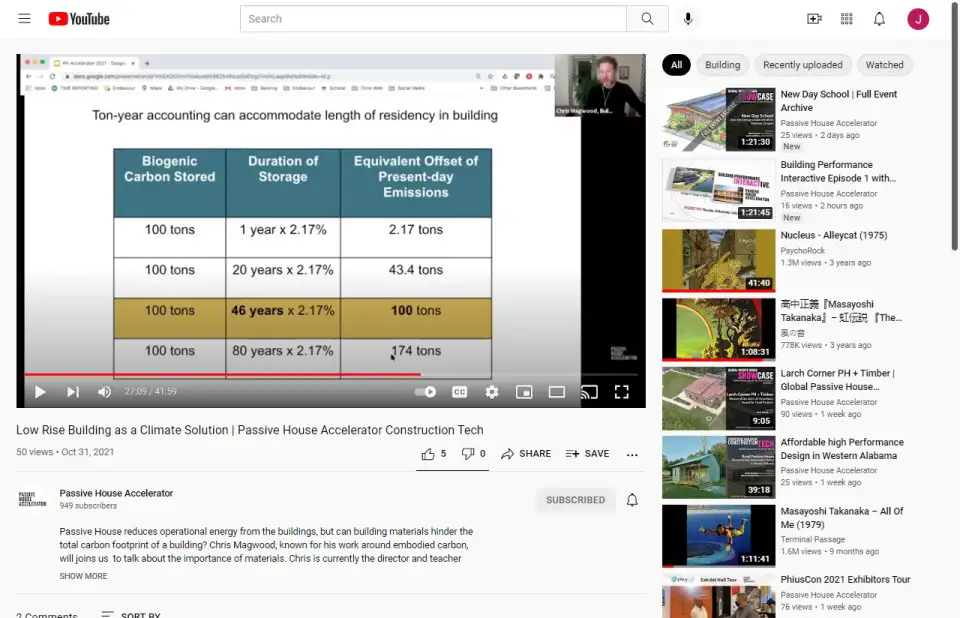

And then we can also use 10-year accounting to sort of weight the value of that carbon storage if it's there for less or more time than 40 years. So if I put 100 tons in a building and it's only there for one year, then it's offset value is 1/46 of its weight in carbon. If it's there for 20 years, it's almost half the amount. If it's there for the 46 years, my 100 tons in the building literally has offset 100 tons. If it's there for longer, it's actually offset more than 100 tons. It's done more work because it's been out of the atmosphere longer. So, built into the sort of tool that we built is that logic. If a product has a 30-year life span, then I'm using the 30-year storage value. If it's got a 50-year, I'm using the 50-year. We can sort of fine tune the meaning of that carbon storage using that ton year accounting.

So I'm working right now with my colleagues on a study for the Toronto region. It's with Passive Buildings Canada and sponsored by or funded by The Atmospheric Fund. We're actually doing case studies of 100 recently built homes in the Toronto region. It's the first time that somebody's bench marked that many homes. And I just wanted to give you a sense, we're not quite done yet, but here on the left are the results from that NRCan study. So our worst case model was just under 140 tons for a two story building in Toronto. Our mid range was 30 and our sort of best available materials was minus 20.

When we actually are doing as-built homes, here's what we found: 88 tons is the worst for a two story home. So the worst isn't as bad as our worst case scenario. But the very best home in that entire study, for a two story home anyway is 50 tons, which is a whole lot worse than our sort of mid range estimate over here. So as we look at real buildings, we're finding that they're all landing in between the red and the blue sort of model in real life. So it's not the absolute worse case scenario, but it's far, far, far from the best case scenario. We'll have that study out first thing in the new year, so I'll make sure that I send it everybody's way so that it gets seen.

We also just finished for the cities of Nelson and Castlegar B.C., and we did 35 homes there. Again, these are actual as-built examples. There we found that the average house was 26 tons and again, bracketed quite widely by 63 as the highest result and 5.9 as the best result. So the average looks good compared to the other study, but again, there's this wide range that they fall in and so it's super important to know that in the same region within the same couple of years, people buying materials from the same store can turn out a 63-ton house or a six-ton house. And it had nothing to do with its level of energy efficiency or it really comes down to material selection.

Average operational emissions from those homes were one and a quarter tons per house. So again, we sort of can see a wide bracket, well under a ton of 1.4 was the best result and almost five was the worst result. So same kind of thing. The possible range is really wide. But if we take the average, again, we see the thing that keeps happening of it takes at least 20 years of operations if we use the average from this study before operations have caught up to materials.

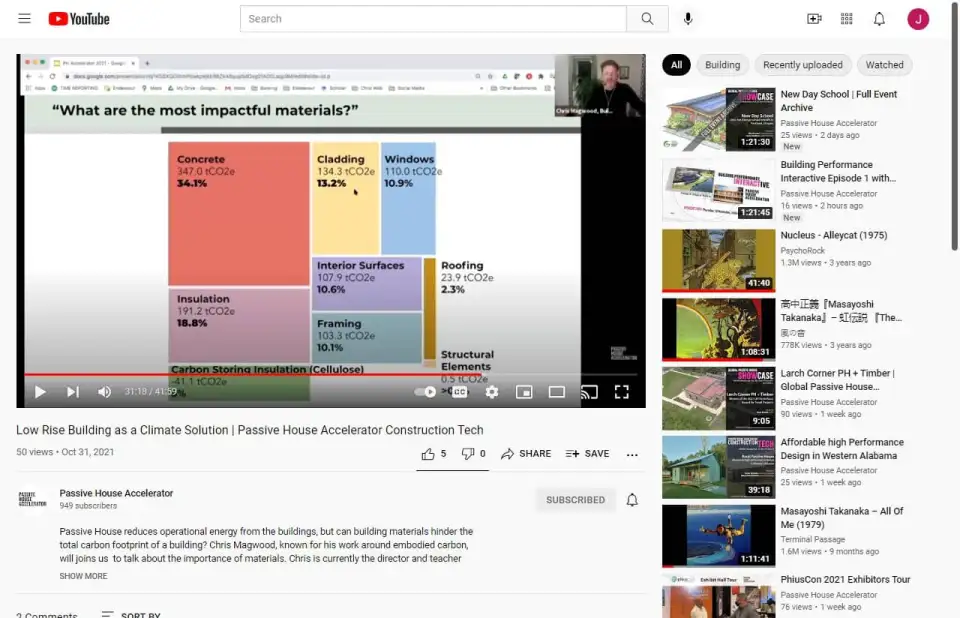

And from that Nelson study, this is how the material categories broke down. When we amalgamated all the results and all the materials out of that study of 35 buildings, concrete was responsible for the biggest chunk of emissions. So across the whole study just over 34% of all the emissions were concrete. Insulation came next at 18.8%. Cladding at 13.2%. Windows and interior surfaces, interior surfaces being flooring, wall board and ceilings, are pretty similar at around 10%. Framing is also around 10%. Roofing pretty small at 2%. Structural elements like posts and beams and things like that were pretty insignificant. Down here at the bottom is the cellulous was the only carbon storing insulation in that study. But there was in total 41 tons of CO2 stored in the cellulous across the study.

That's what it broke down in Nelson and it's pretty similar to how it looks like it's breaking down in Toronto and likely across North America. The one that changes a lot can be cladding. Places that use a lot of brick that tends to be higher, places that use sort of more wood and vinyl tends to be lower. But this kind of breakdown is pretty typical. One thing we did for the builders in Nelson was we took the house that had the worst results and we sort of looked for the low hanging fruit were we could make a really big difference in the carbon footprint with just a small number of changes.

We took the average concrete from that building and subbed out the results for a high SCM concrete. So something with a lot of slag or fly ash in it, and also a Portland limestone cement. We changed the foam ICFs for wood ICFs. We changed the mineral wall insulation for cellulose. We changed the XPS continuous that that building had for wood fiber board on the outside. It had hardwood floors throughout, we changed half of those to linoleum and we put cellulous in the roof instead of mineral wool. And we halved the carbon footprint of that building. So six relatively straightforward steps, nothing that is too difficult to achieve. In a lot of cases, not necessarily even more expensive to achieve, And we can cut the carbon footprint in half. We haven't addressed the design of the building or anything; it's just these six material interventions.

And then we decided to pick six where we could take it a little further, so we changed the EPS that it had under its slab for foam glass gravel. Again, we switched out the concrete. We changed the ICFs to a treated wood foundation, changed the walls to straw bales, changed the floors to a mix of linoleum and cork, and we put cellulous in the roof again. That brought that 300 kilogram per square meter house down to just 55. Again, a handful of material swaps. The ones on the right may not be ones you're going to jump to immediately. They may not be things that you're considering, but all achievable, all things that people have done and a pretty dramatic 10th of the carbon footprint of the original house.

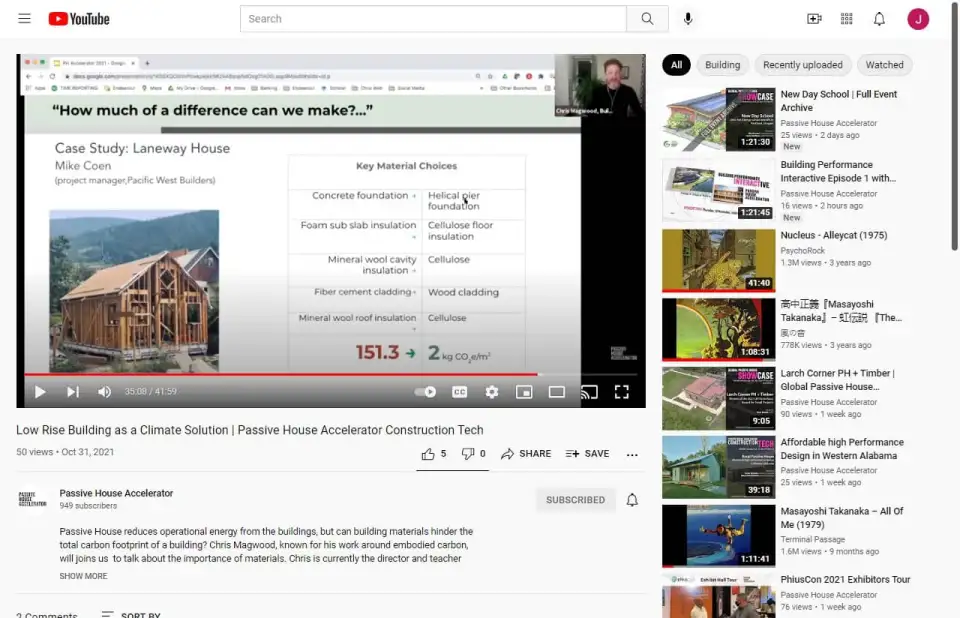

In that Nelson study, this house came to our attention after we had run the study, but the energy advisor who is helping us out there said, "Hey I think I've got a pretty interesting little building." I ran it through the calculator, just because I was curious and it has a two kilograms of CO2 per meter squared. So essentially a zero-carbon house on the material side. And the biggest things that contributed to that were it had not concrete in the foundation. It's up on helical piers, that allowed it to have cellulous in the floor instead of any kind of foam in the slab. Cellulous wall insulation, wood cladding and cellulous roof insulation. Not terribly radical as far as a building goes, but a radical change from sort of the average of that study in the 150 range down to basically a zero-carbon building. It was great in that study to be able to talk to the builders and other folks in those two municipalities and say like, "This is actually going on in your jurisdiction right now. You could be building this. Everybody could be building this." You don't have to necessarily build it this way, with these materials, but these kinds of results in terms of carbon footprint are achievable. It's not a pipe dream or anything.

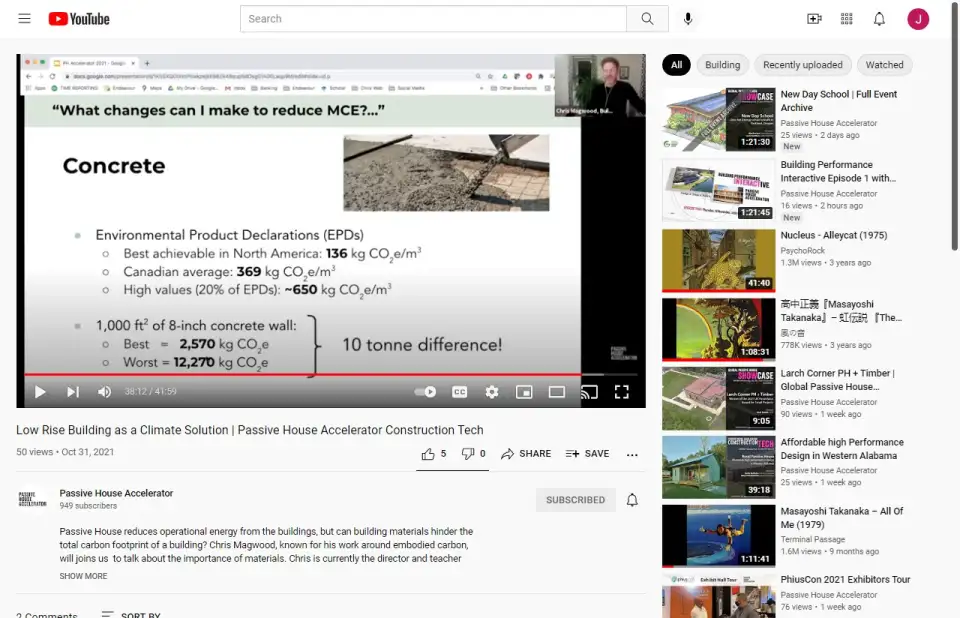

So I wanted to dive a little bit into the concrete because it does end up in most residential buildings, being a pretty significant portion of the carbon footprint. Obviously there're things you can do like not use it or reduce how much you're using it. So by sheer volume you can make a difference. But also, asking your suppliers for A, just to know what the carbon footprint of your concrete is, is really helpful. And B, pushing them to start offering lower carbon mixes. So when I look at the concrete EPDs that are available across North America, I can see that there's a best achievable of only 136 kilograms of emissions per cubic meter from concrete. And I can see that about 20% of the EPDs are above 650 kilograms per cubic meter. That's a big split.

When you get to site and it's coming out of the spout, it just looks like concrete. There's no performance difference, this is for the same PSI. It's for the same basic residential mix that anybody would use, but there's this giant gap. For our studies we're using this Canadian average of 369 kilograms per cubic meter. But by and large, we don't even know what people are using, because most ready mix plants that are supplying residential buildings aren't producing EPDs. So one of the things you can do is start asking your concrete supplier, "Hey, can you make me an EPD for this mix that I'm getting?" And if the number look terrible, like this one 650, ask them to do better or take your business elsewhere if you can, because there's lots of things that they can do to bring that down.

And just the difference here is if we use the best number, the same wall, 1,000 square feet of 18" wall could have two and a half tons of emissions or over 12 tons of emissions. So there's a 10 ton difference. It's still a concrete wall. If you looked at it, if you built a house on it, you would not know there's any difference but the climate feels that kind of 10 tons per house difference. So everything we can do to make sure that we're bending that down is really great.

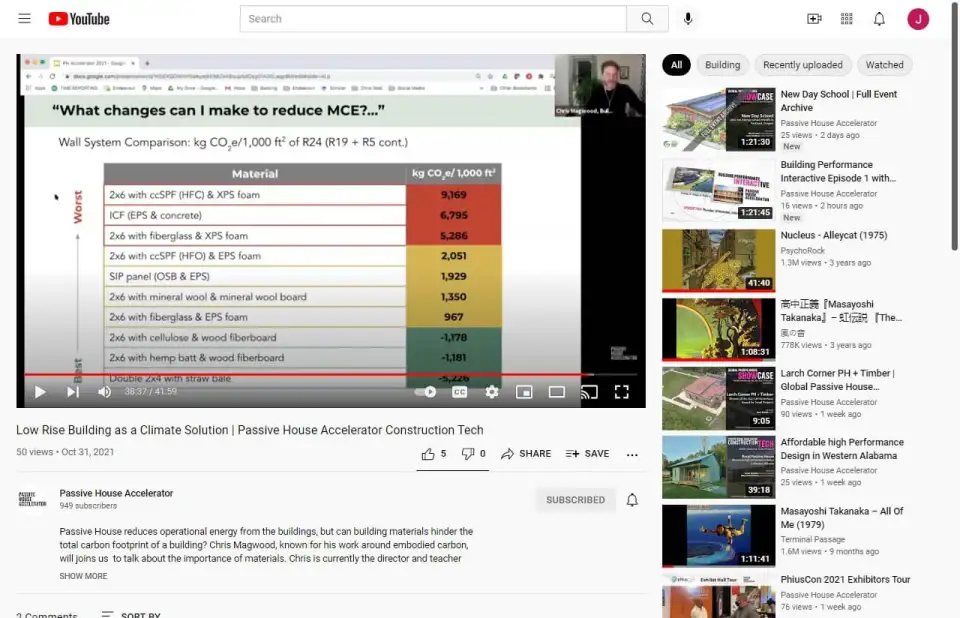

For Nelson, we sort of did this little wall systems comparison. We just looked at some of the ones that were quite common across the houses we studied there. And you can see basically we tried to normalize this so that all of these are achieving and R24 level of performance. And we can get anything from nine tons of emissions from the worst case to five tons of storage in the best case, and kind of everything in between. So thinking about how we picked those materials, what goes into the assembly is really important. I know there's a lot of people ... I get more email about this than anything else ... "Yeah, there's this new XPS formula coming out. It's a really game changer." It's kind of a game changer. It changes XPS from being shockingly by far the worst insulation to being just the worst by a little bit. It's not going to change the world, but it is a pretty significant improvement and it makes it about the same as doing a mineral wall cavity and mineral wall board on the outside. I'm glad that that's happening, but it's not the silver bullet that it's sometimes being made out to be.

This was interesting. I hadn't really thought about this because in my practice I don't really build houses for cars, but a lot of people do. So 19 of the 35 homes in Nelson, have garages and they had 122 tons of emissions just from the materials that go into the garage. So basically 20-odd percent of the emissions from houses that have garages were attributable to the garage. So if you want to cut the carbon footprint of your building down, don't make a building for a car. You can knock a fifth off your total right there. Don't do anything else, just don't make a house for a car.

So I'll go through this quickly. These are the takeaway points for the group in Nelson. I really want to make sure people look at the first two here. Even though I'm saying that material emissions are a lot bigger than operating emissions, I am not at all suggesting that we give up on operational emissions and only think about materials. I really think these two things need to go hand in hand. The kind of results when you actually get a real zero carbon building, it really has to be net-zero on the operational side, and it needs to be zero on the material side. You can't really just put all your attention in one place or the other. We really have to be doing these things hand in hand and really thinking about them holistically that way.