3D printing is currently one of the hottest topics in the construction industry, but media coverage on the technology is often filled with hyperbole and over-promises. This presentation by Belinda Carr of Carr Builds will take you on a deep dive into the 3D printed home industry. Belinda is a Building Science Researcher with a background in architecture and building information modeling (BIM), who runs a YouTube channel where she explores various topics on building science, products, and technology. You can read the transcript below for the video.

Belinda Carr:

Thanks again for inviting me onto this podcast. I really appreciate it. This is pretty awesome. Y'all doing this every single week is a big commitment and spreading all this knowledge and welcoming questions. It's very impressive and I'm so glad to be a part of it. Thanks again. I'm going to share my screen. So a couple of... Last year. Sorry.

Yeah, so a couple of months ago, I believe it was last year, maybe 10 months ago, I made a video on the truths and lies about 3D printed homes, because it's one of the hottest topics in the construction industry right now, I feel. Everywhere you look, people are talking about the reality of 3D printing, or what problems it can solve and, like I had done with the shipping container video, I was trying to go past all the hype and see what this technology can actually do, how it really works, and I want to share some of that information in today's presentation. But I want to go past all the information I did post in my video, and share with you all what I have learned since then. Because I have contacted a lot of companies, had a lot of companies on my podcast and learned so much about this industry and it's extremely exciting.

It's such a new industry and there's so much growth involved in it and people are working nonstop to figure out what potential this has, so it's a very exciting industry, so I think my presentation's going to be a four part structure. I'm going to talk about what 3D printing is. I'm going to talk about the truth about 3D printing, and then I'm going to share what some 3D printing companies around the world are currently working on. What problems they're trying to solve and what niche they're trying to make their mark in. And then we are going to end it talking about my experience staying at a 3D printed home in Austin, right?

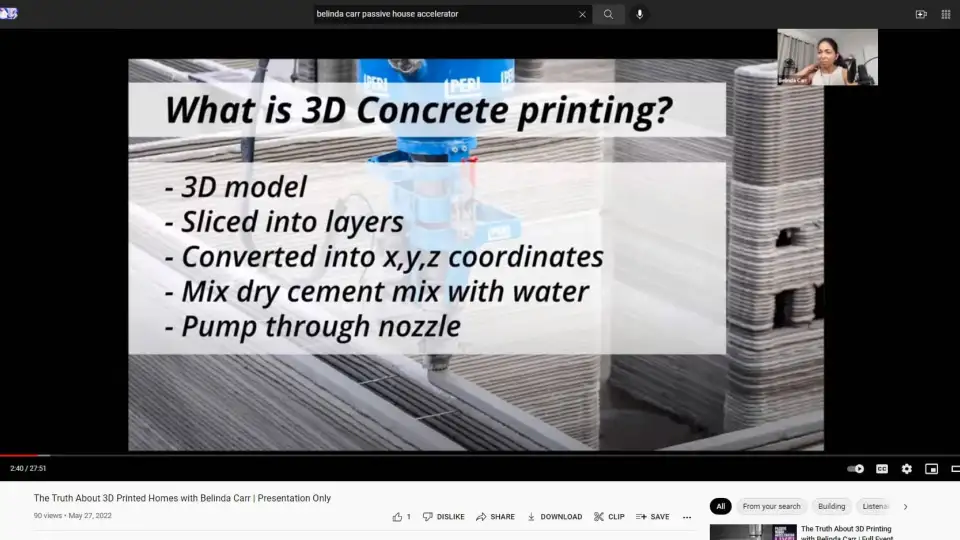

Just a brief intro about 3D concrete printing, a very, very oversimplified introduction, just to anyone who doesn't know what 3D concrete printing is. I have a PLA printer in my home here, and many of you all might have that too. So a 3D concrete printer operates in a very similar fashion to a home printer, if y'all have played around with that. 3D printing is basically an additive manufacturing technique. Instead of taking material away, like a subtractive technique, it adds material. It prints material layer upon layer to create a three dimensional structure.

The main steps in the 3D concrete printing processes, obviously you start with the 3D model that you have made in some version of a CAD software, whether it's Revit or AutoCAD or Rhino Grasshopper, whatever software you prefer to use, you come up with this 3D model and then you slice it into layers.

After you slice it into layers, you convert that into what's called Gcode, it's basically X, Y and Z coordinates of every point on the wall. So that information, those X, Y and Z coordinates affect to a machine, which tells the printer head, if we're talking about X and Y coordinates, that's whether it is left or right, it's on a single plane, so that tells the printer where it needs to pump out material on a single plane. The Z coordinate, obviously, is in the vertical direction. So it's telling the printer, "Move up. After you print a layer, move up to the next layer, print it." So that's the X, Y and Z coordinates.

The printer itself is, so y'all know, concrete is cementless, plus aggregates, plus water. The difference with 3D concrete printing, because all this material is being pushed through a nozzle head, you can't have large aggregates because you're going to clog up the nozzle head. So this is basically a mortar mix and not a concrete mix, so 3D concrete printing is actually like 3D motor printing. But, obviously, we are still in the first iterations of this material and of this technology. Right now, people are adding strength to the mix by using fiber reinforcement or all sorts of other substitutes for regular aggregates. And they're trying to see what else can we use other than mortar, because mortar by itself is obviously energy intensive, so by adding aggregates to it, you could reduce the amount of cement in the concrete mix. But anyway, so these are the main steps in the 3D concrete printing process.

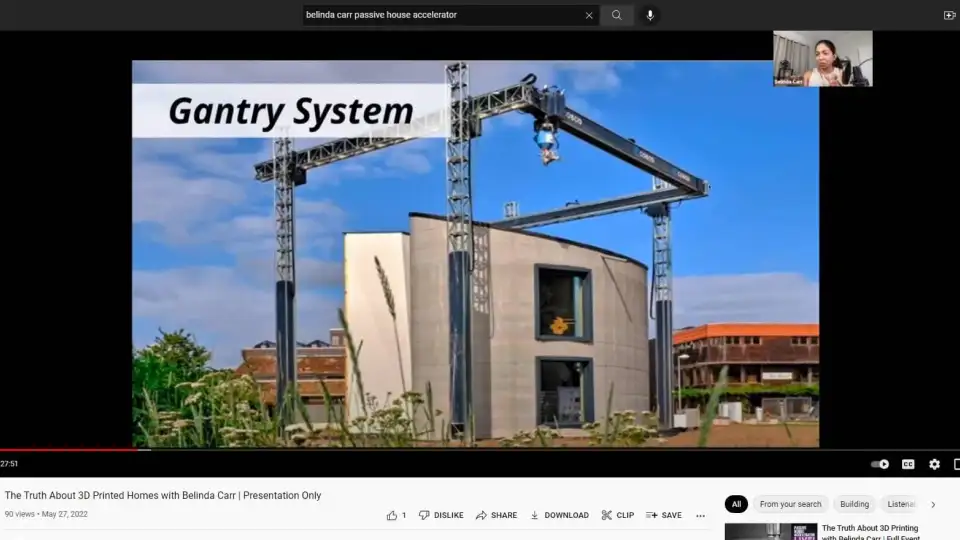

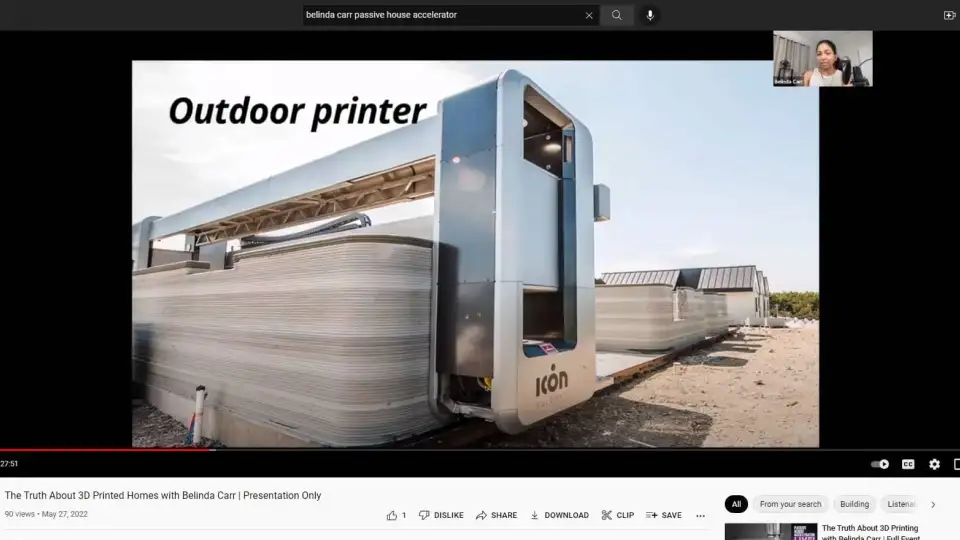

Now the printer itself, there are two main types of printers. One is a gantry system which consists of these four vertical towers that support a horizontal system on top. So the system up here is basically called a gantry. I'm sorry. The nozzle head here can move sideways, like X and Y, and then this whole rig up here can move up and down. That's in the Z direction.

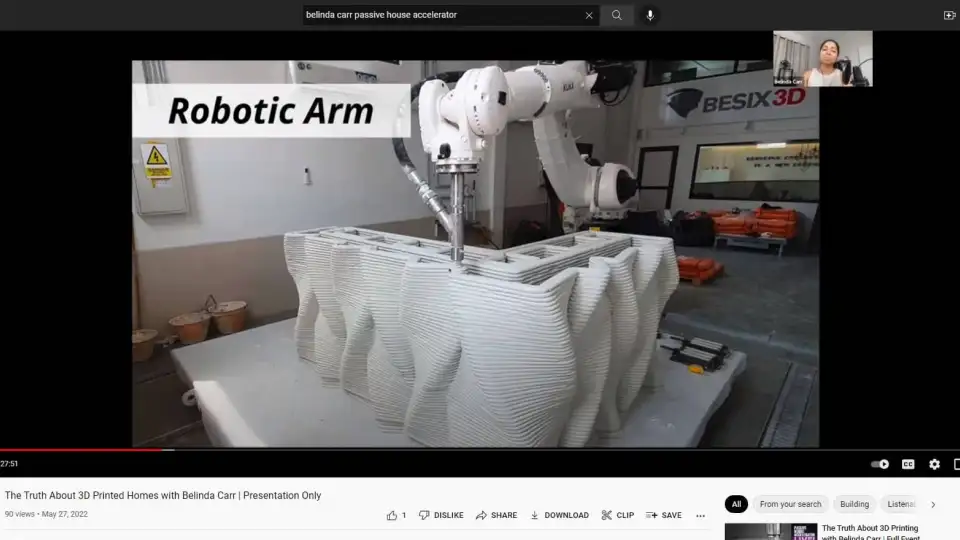

The other type of system is a robotic arm, so that sits in one location, and robotic arms are used all around the world for all sorts of things. On cruise ships, they're used to make drinks. Over here, you're using the same robotic arm, just the head is different using a nozzle head over here. That can move again, because of the pivot points, it can move in the X, Y and the Z direction.

So 3D concrete printing can occur, both in an indoor environment, like in an enclosed facility where you control the temperature and humidity levels and moisture levels. In the beginning, when people first started experimenting with 3D concrete printing, many of the prints were occurring indoors because you have better control over variables, and mortar mixes weren't as... They had a lower margin of error, basically.

But we have learned a lot in the last couple of years, and we are now able to print outdoors. The motor mixes are more resilient, so they can be exposed to the elements, and the obvious advantage of printing outdoors is you're saving on transportation costs. You don't have to print it in a facility and then spend money transporting into the site. You are basically printing on a concrete slab, and once the print is done and the walls have cured, it's done. It's set in place. All right, so that was the first part of the presentation. We are not taking questions right now, we're just going to continue.

Okay. So now this brings us to the second part of the presentation. We're just going to go over some of the common myths that about 3D concrete printing. Things that I've heard a lot of people regurgitate because of articles that would release... Promoting these myths and hyperbole. And one of them was 3D printed homes can be built for less than $4,000. That's not true. These lies started circulating in, I think, around 2018. This article was in 2019.

Some companies claim to print a home for $10,000, but when they scale it up, they believed they could bring costs down to $4,000. And that's the problem. This is such a new industry. There are so many variables involved. Every company's using a different concrete mix and everyone is just in an experimental stage and no one has scaled up. You can't make such claims, because they're just unfounded.

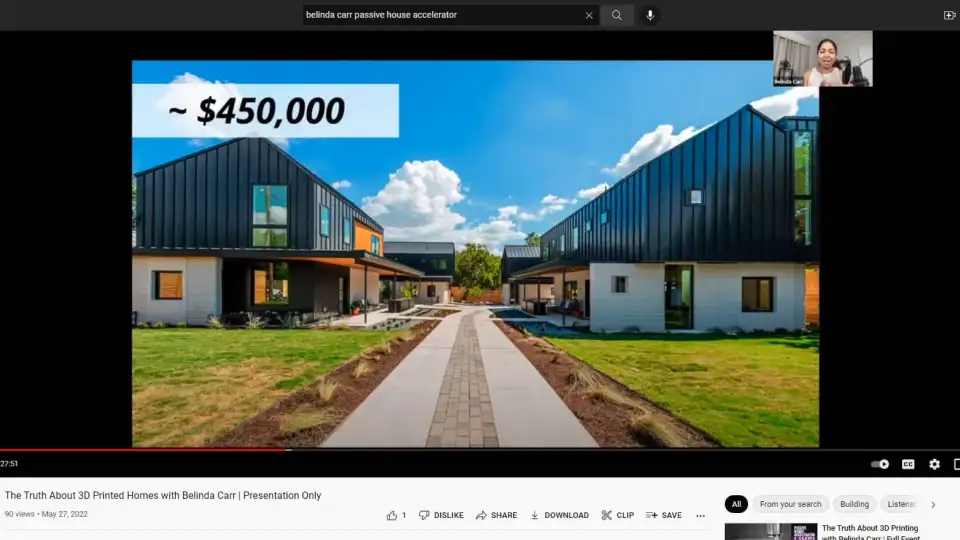

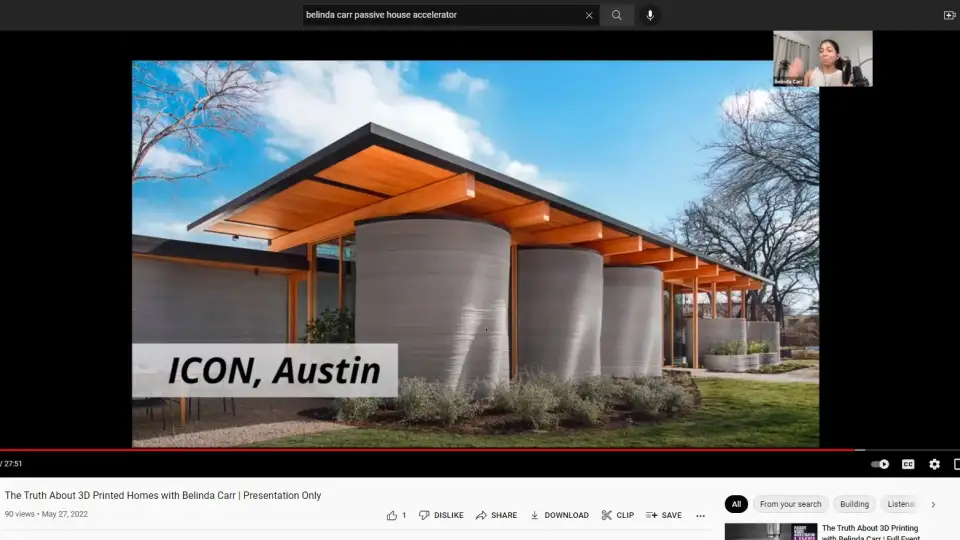

For example, some of you all might know this little community that's been printed by ICON 3Stands in Austin. The approximate cost of one of these homes is $450,000. They're beautiful homes. I mean the cost's probably justified, considering where they're located and how well they're built, but again, it's not $4,000. I think the other variable we have to consider is that we have to consider local costs. Before this blip in lumber prices, wood construction was probably the cheapest in the US, or in other places, CMU constructions cheaper or steel construction might be cheaper. We can't say that 3D concrete printing is going to be the cheapest solution everywhere in the world. Construction is so site specific. There's so many variables involved around the world that there is no one solution fits all when it comes to construction or architecture or engineering. It's site dependent. It's based on culture and traditions and history.

I keep emphasizing that whenever I talk about the complexities of the AC industry. Another myth is that 3D printed homes can be printed in 24 hours, so these printers print walls and not homes. A house or a home has so many other components to it, whether it's electrical, plumbing, insulation, roofing, pouring the slab before you start printing. There is just so much more to it than just printing walls. If you ever read claims of printing in 24 hours, they are ignoring the setup time to set up this printer, to calibrate the printer once it's on site, and then even the curing time, because obviously, you can't print all these layers at once. You have to print a couple of layers, wait for them to cure, too harden, and then they're stable enough to print the next couple of layers. Printing time is not the same as the construction deck to build the homes. They're two completely different things, and companies should be open about that distinction.

Another lie, or myth, not lie, is that 3D concrete printing will make jobs unnecessary. It's going to solve this worker shortage and we're going to completely eliminate humans out on job sites. I don't think that is true because you're automating a part of the construction of walls, but you're still going to have people operating the machines and monitoring it. You're going to have people involved in the setup and the dismantle and then, again, there's so many other components to building a home, with its electrical and plumbing and all that stuff. The printer is not going to automate all the other processes involved.

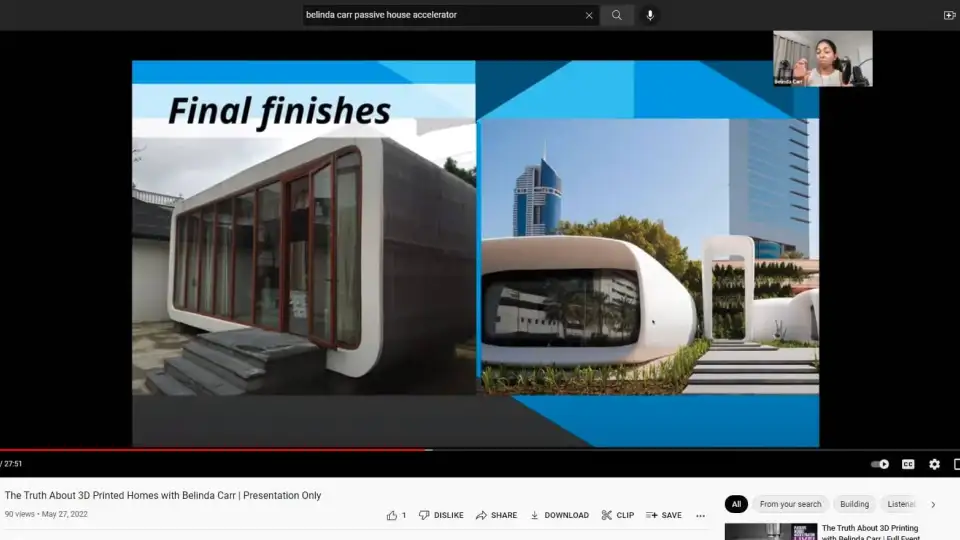

There was another point I wanted to say when it came to this. Yeah, okay, here. Here we go. So related to this, to the idea of making jobs unnecessary, this is one of the earliest 3D concrete printing modules that was shown off in Dubai, my home there. Everyone saw this lovely little pretty picture, polished picture, on the right and was fascinated like, "Oh wow, that whole thing was made by a machine, and no humans were involved in it?" Well, COBOD is one of the biggest 3D concrete printing companies in the world. They showed us the reality of what it really looked like before all the touch-ups, the manual touch-ups. This is what it looked like. You see the striations here on the right and how uneven it is. That was it in its raw form in China and then it was shipped the UAE where they added all these other features. They replaced the glass, smoothened out all the exterior walls, all that was done by humans, so I think humans are still going to be heavily involved in construction. 3D concrete printers, they tackle one tiny element of the entire building.

The next and final... No, second last thing I'm going to tackle is that 3D concrete printing can solve homelessness, and it bothers me, because that's something... I feel that's arrogance and it's oversimplifying an extremely complex problem. In architecture school too, where we have all these issues that we are presented with like, "Come up with the solution that can solve the housing crisis, or the homelessness crisis,' and a building itself is not going to do that. We need several other industries involved in this extremely complex and extremely disturbing problem. Whether it's psychiatrists or people assisting in job searches or in healthcare. There's so many issues rather than just putting a roof over your head.

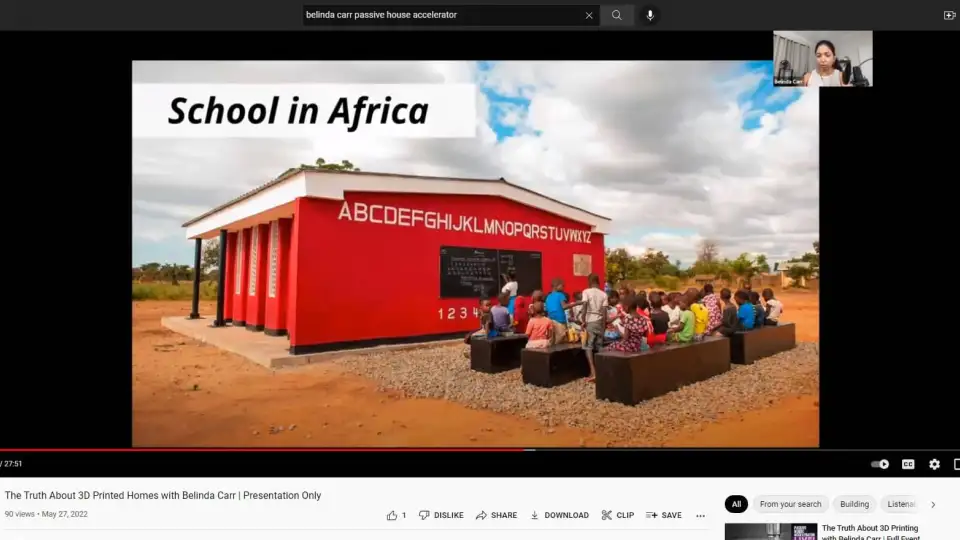

Solving one thing and not addressing all the others is not going to fix the problem. So, again, related to this idea of solving homelessness is, there's a company printing schools in Africa. I think it's a noble cause, it's a noble attempt, and I hope it does work out, but I did speak to a local builder in Africa and asked him what his thoughts were on this, and whether 3D printing could actually solve the lack of housing that's currently in Africa. He believed that it didn't and he proposed some really solid arguments why. Because I don't have any personal experience building in Africa, so I'm not going to claim that I'm very knowledgeable about the local construction technique, so I'd rather just present his views on it.

He said that it's a far more complex problem, even if you print these precise walls, it is very difficult to get windows or doors that will fit into the precise openings made by a printer, because there is a large margin of error. He has noticed a large margin of error when it comes to, like I said, the windows or the doors, or any other elements that need to be added to a home. Inconsistency is a big problem over there. And then he was talking about the additional labor needed to bring in generators because of frequent power outages, and then having 24 hours security to make sure that the printer itself is not going to be stolen or damaged. Then he said that shipping the printer into Africa is going to be a huge hurdle because of bribery and corruption and all that at ports. Getting the machine out of the port to your job site is going to be a huge expense, getting it clear at the port. Then in addition to that, there aren't any paved roads in all of these areas, so this is a expensive, fragile, fragile in a certain way, machine.

You don't want it to be damaged while it's driving on dirt roads, so that was one of his major concerns. Yeah. So again, it is such a complex issue that we cannot oversimplify it into, "Let's just take a printer, plop it in Africa and hey, we have solved the homelessness issue." We have to make intelligent and really, we have to discuss this in more detail, can't overly the problem.

Finally, 3D printing is sustainable. I've made a video on the hypocrisy of being green and sustainable and how liberally we use that word and what does it really mean anymore? I agree that we can cut down construction waste out on job sites, if we can calculate the exact amount of motor mix required to print a home, so we only bring the amount that we need to a job site. We are not wasting anything. Even when it comes to mixing the mix with water, mixing the mortar with water, we only mix as much as is needed, so we are not wasting. So in that sense, yeah, I agree. We can cut down on construction waste. That's a form of sustainability, but concrete in itself is not the most sustainable material. I love the solidity of concrete and I think it's wonderful material. It's helped us tame nature in a lot of ways, but its carbon footprint is a major concern. That's just an image talking about sustainability of using concrete.

This brings me to the third part of the presentation. Since I made that video, I have, I have talked to a lot of 3D concrete printing companies around the world and asked them what they're doing. And it's really eye-opening and it's made me appreciate how much innovation's going on in the field and how hard people are working to figure out the potential of this new technology and what we can actually do with it. Maybe eventually we are not going to be printing homes. Maybe there's a far better application for it, but people are working really hard to figure this out.

Many companies around the world like Hyperion Robotics in Finland, they are, I think, a bunch of really, really smart engineers that have chosen to use a 3D concrete printer for engineering applications rather than architecture, that they have no interest in printing homes. I think they're printing bases for electrical towers or, I think footings for buildings or something like that. They're trying to use, and I believe one of their proposals used 75% less concrete for a footing, because they calculated exactly how much concrete would be needed, rather than just dumping concrete into a cuboidal form, and just having a solid block of concrete, they figured out where concrete was needed and what would be the ideal shape of a footing. They were able to bring the amount of concrete used down to... Cut it down to 75% or 25% of the original form.

Another one is Vertico in the Netherlands. Again, really, really smart guys, and when I say guys, I'm including men and women, they're experimenting with different nozzle heads. What's the next generation? What's the most resilient nozzle head or 3D printed design? They're also experimenting in certain motor mixes, but I think they refine the 3D concrete printer and nozzle head itself.

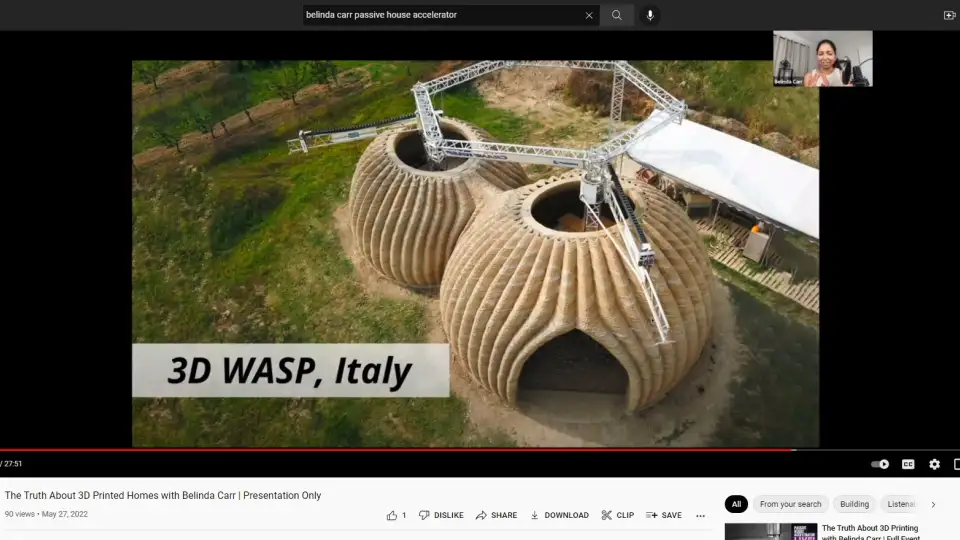

Then there're companies like 3D WASP in Italy, that decided, "Hey, let's experiment and see what happens if we used earth rather than motor mixes or concrete mixes," they wanted to make something more sustainable, use a more sustainable mix. They made these two very interesting domes out of local earth rather than concrete.

This is a company I recently visited just two weeks ago, Apis Cor in Florida, really, really cool. They have a showroom in Melbourne and they have put wheels on their robotic concrete printer. So rather than it being stationary, their idea, you can see this kind of looks like a mini tank. But of course, it has these supports so that it's stable on the ground, it's not going to move while it's printing. But their idea is that the robotic arm can print a certain part of the building, then drive off to another area and then print that other area. They believe that this is a more viable solution in the long run, rather than the big gantry system that I talked about earlier, because they think that the gantry system is... When you disassemble and reassemble things, like with Ikea furniture, things just don't fit the same way the second time or the third time. Things get loose, and it's just... How many times can you realistically reuse elements? That's their theory, so they have gone down the path of exploring the potential of a robotic arm printer, rather than a gantry system.

And of course there is ICON in Austin. Again, one of the biggest, and local, 3D concrete printing companies. They have gone down a very interesting path, which brings me to the last part of this presentation. Their prints, and the one word that comes to mind is just, refinement. I visited another 3D concrete home in Canada, and I've seen a couple of other 3D concrete printing projects, but ICON is startling style and refinement, in a really beautiful way and I really respect them.

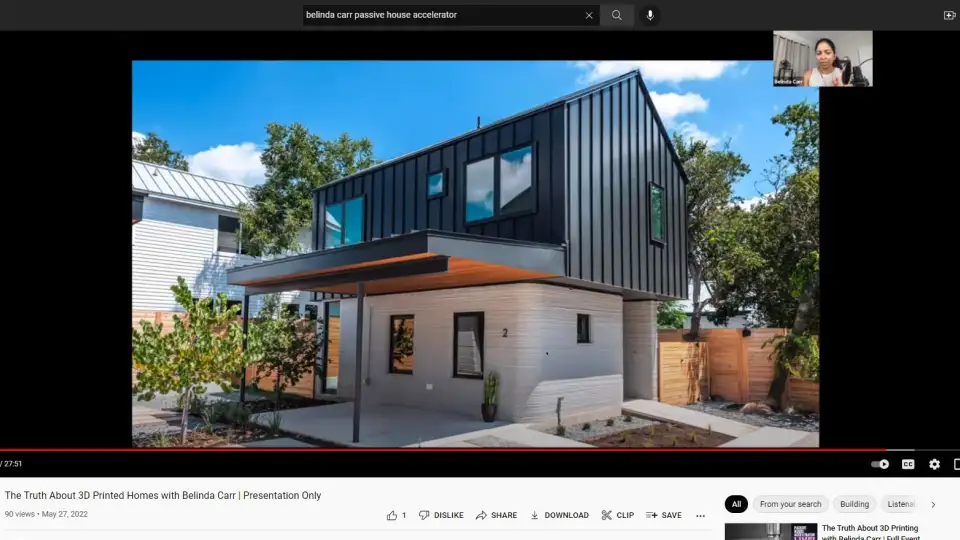

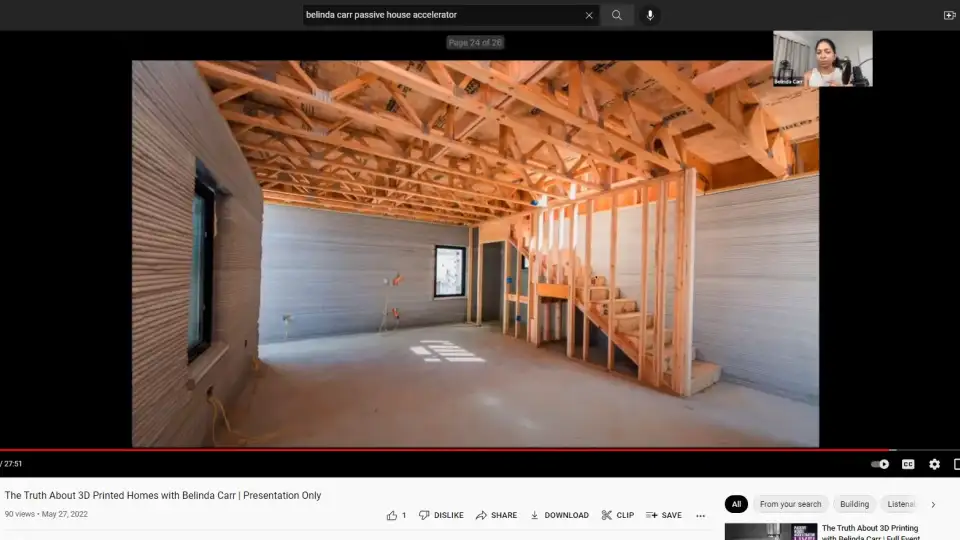

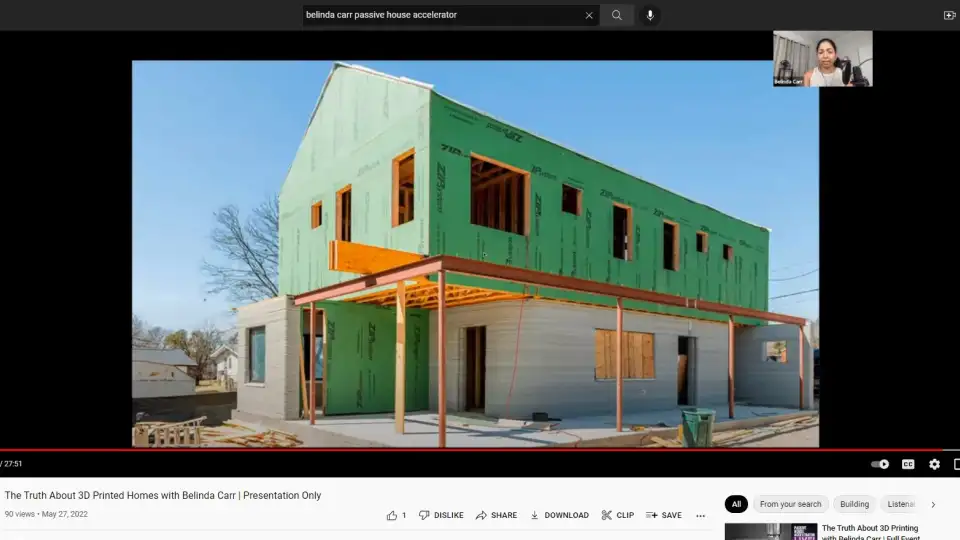

This was the home that I stayed at overnight last year, I think in November. This is a home in Austin, so the lower part, as you can see, is made of concrete and the upper part, maybe this will be more useful. The upper part was made with traditional stick building. So they collaborate really well with the architects, with the engineers, and they want to come up with something that makes Austin, and the inhabitant really proud. Once you're in that home, you feel like you're a part of history. You feel like something is different. The moment you walk in it, it's just very polished and super quiet because, it's basically a concrete home, and they just take a lot of care in how the home is presented to people and I really appreciated that.

As you can see here, the prints were not as refined as it is now. You can see, by the window, it bulges out. There's a lot of things that they have improved. This is their most recent home. I think it's called House Zero in Austin. I haven't visited this one, but there's significant improvements compared to this earlier home, which they printed one and a half years ago, I believe. So, again, they used a SIP system, traditional wood framing for the upper floor and then concrete on the lower floor.

I'm just going to end it with this slide, and then we can have a follow up discussion. So, when I visited this ICON home, they teamed up with this company called Positive Energy in Austin, and what I really appreciated about it is they didn't just print the walls and then say, "Okay, we're done. Now figure out how the house is going to function." They care about how the house is function. Positive Energy really cares. The interior designers really cared about what the interiors feel like. Everything was so cohesive and worked so well. It felt like a really polished project and Positive Energy, especially, I feel like they did a really good job with this. They had an ERV, energy recovery ventilator, so air was constantly being circulated in the home, but it was so super quiet. You couldn't hear it. In my home, I've got a 25-year-old condensing unit, so every time the AC kicks on in summer, the lights flicker and hear this loud noise, when the fan starts turning. Nothing like that. It was eerily quiet in this home. It was so beautifully executed.

So, I just want to say that, we talked about the myths about 3D concrete printing, but this is such a new industry and there is so much research and innovation going on, it is an extremely exciting industry to be in. I hope that more people, more companies like ICON start teaming up with other companies and engineering companies and architecture companies to figure out the potential and start building better. It's not just about printing a home, printing the walls and that's a bit done. It's about building better homes. The walls itself are not going to help us build better homes, but how we work together and start collaborating with each other, share knowledge and share ideas, and that's how we can build better.

Related Videos

5/18/22

Environmental Charter School: Living and Proving the Mission

Video, PHA Live

5/16/22

Top Ten Ways to Know You Are Buying Quality Windows, with Sam McAfee, Zola Windows

Video, Fenestration, PH Component Spotlight

5/11/22

Zero Six: Urban Passive House in the New Age of Adaptation

Video, PHA Live