As the design community has made great strides in reducing operational carbon, the question remains: How can we also begin to address the emissions associated with building materials and construction and the full life cycle of our projects? Carbon Leadership Forum senior researcher Steph Carlisle addressed this question and more in her in-depth session focusing on the growing list of tools available to designers to measure, compare and reduce the embodied carbon on projects. She discussed how to pick the right tool for your project and workflow, where LCA data comes from, and gave a brief introduction to the science of life cycle assessment models that underpins this type of analysis. You can read the transcript from the January 25, 2022, event below or watch the video by clicking on the image above.

Stephanie Carlisle:

So I'm super happy to be here with all of you. Thank you for the kind introduction. It's such a pleasure and thank you for keying up some good energy. I feel like the evening webinar game can be a bit of a drag after a long day. So I feel jazzed and excited. I was told that this was a wonky, delightful, eager to get into the weeds audience. So I'm going to go there, right? I also want to make sure that this talk is accessible and that you guys know what I'm talking about and that everyone gets something out of the talk. So I'm going to lay some groundwork of LCA. I'm going to jive into and talk about tools that hopefully you can use on your projects. Things you can look out for that you might not seen before, and then hopefully we can circle back on whatever questions for anyone who got lost along the way.

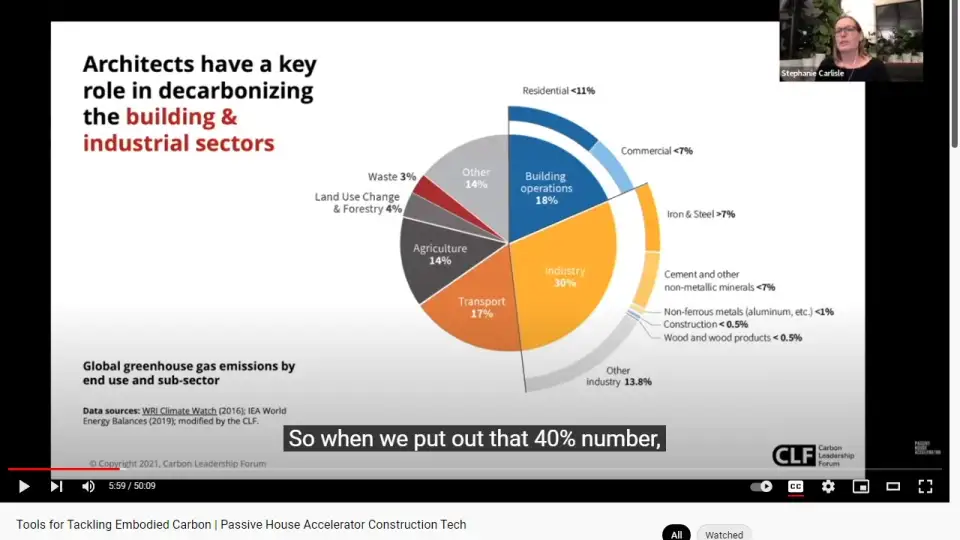

We will throw out a whole bunch of learning resources. So hopefully there is something for everyone here today. I'm going to keep the climate change intro to a minimum, because we know hopefully all of us are united in understanding that the way that we build is not so awesome, right? But also that we have enormous amount of opportunities. So presently buildings and infrastructure account for about 40% of all global CO2 emissions, that is an enormous number. It is a shocking number. It's something I still cannot totally wrap my head around as a practitioner, and with all of the other things that we know that buildings and infrastructure are also essential, essential for our communities and essential for our future. So how do we wrap our heads around those two things and how do we figure out better ways that we could be building? We also know that we are building an enormous amount, right?

So between now and 2050, embodied carbon itself full account for nearly half of all construction emissions. So right at this critical time in which we need to dramatically curb carbon emissions. We are using tons and tons of really intensive materials and those materials matter, and we need to consider them and think about them really carefully what those impacts are going to be. This practice of LCA of thinking about embodied carbon of taking it to a carbon perspective, I think helps us as designer, as builders as really anyone involved in the AC community. Because it helps us understand the impacts of our design and those design decisions that we make shape communities and landscapes far beyond our building site. Of course, we hope that our buildings affect building inhabitants in really healthy and sustaining and lovely ways, but we also need to think outside those projects, right? So I think the conversation I'm hoping to have today is one of, of course reducing the impact of our projects.

But also thinking more constructively about what are the impacts that we make more broadly in the world and how does that connect to all sorts of different systems. Because if those impacts don't go away when we decide to just not think about them, right? So when I'm thinking about building materials or talking about LCA, it's going to look really data heavy, right? It's going to be a world of numbers and pie charts and graphs, but I always try to stay grounded by thinking about landscapes and thinking about these communities that aren't always present in my day-to-day decision making. Also, understanding that those design decisions also shape communities, right? That the materials that we build with matter and that they too have impacts, and have had historic impacts far outside our building site.

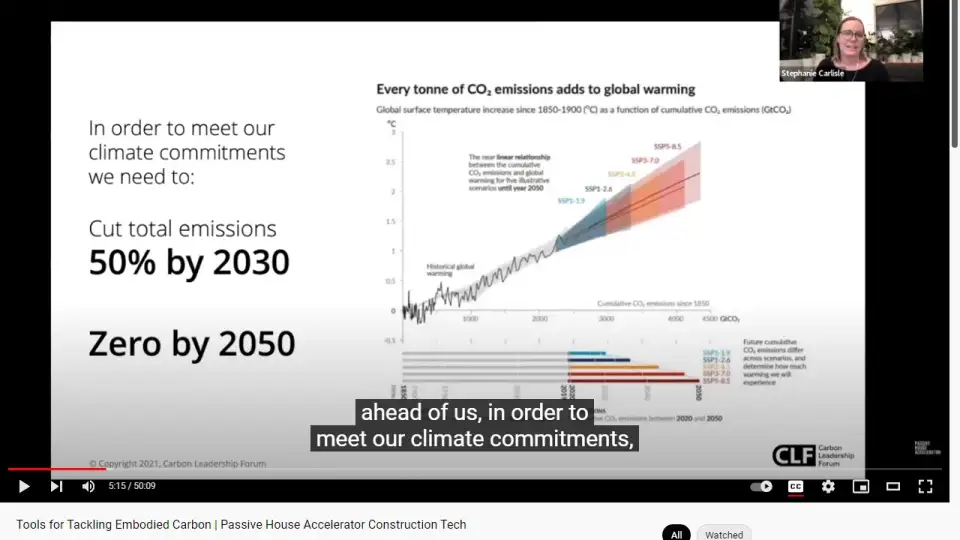

So as I mentioned, we have an enormous challenge ahead of us. In order to meet our climate commitments we need to cut the total global CO2 emissions to 50% by 2030 and to zero by 2050. That is a lot, right? That is an enormous challenge for us to wrap our heads around, and it's really kind of an all hands on deck situation, right? It's a space in which we need to collaborate, we need to support each other and we need to really think about how to embrace innovative and new solutions for construction, which I believe is what this whole community is about.

So I come to this as an architect also as an environmental researcher, and I also want to ground us in this idea of, that's already been mentioned of taking a total carbon perspective. So when we put out that 40% number, that's because we're really thinking broadly. Again, I'm going to use architects, designers and AEC interchangeably. I don't mean to leave out the contractors on the call, the builders, all of the other folks, just gets really hard to say, architects, engineers, consultants, contractors, builders and this whole big lovely community.

So I'll just say, designers, if that's okay with you all. Okay. So I think designers have a key role in decarbonizing the building sector when we think about our building operations, but also much, much more broadly thinking about industrial emissions all together and that's when we start to see those big numbers. So when I start to look at building materials, I'm climbing into, of course, that blue wedge of getting down to electrifying our buildings, of having net zero buildings, of having very, very low emissions buildings. But I'm also encouraging us all to climb into those 7% of total CO2 emissions that are related to iron and steel, to concrete, to cement, the aluminum, the incredible amount of industrial plastics, foams, agricultural feed stocks, the transportation that brings those materials to our job sites, et cetera, et cetera.

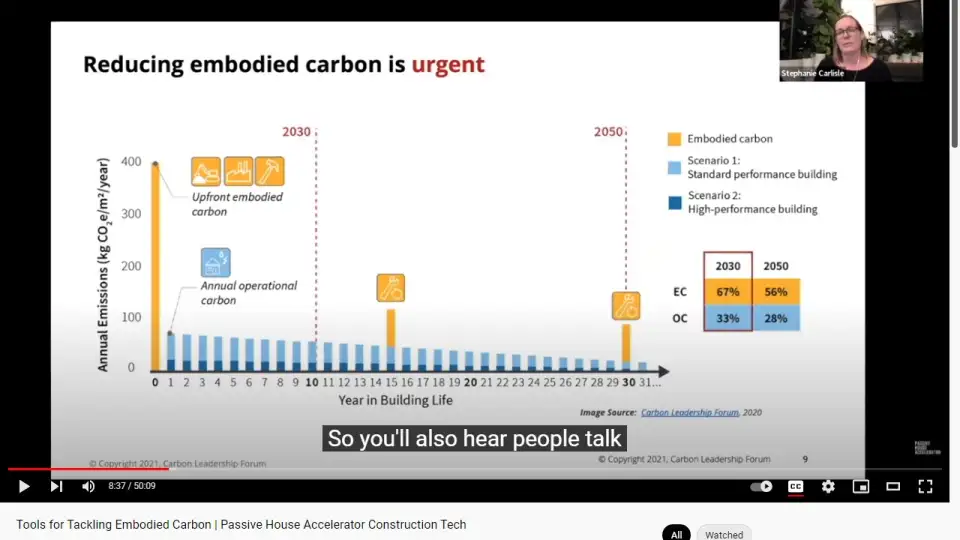

So this brings us into the wonderful world of embodied carbon. So that operational carbon, sometimes it's helpful to think about it on a timeline, operational carbon here in the middle, in blue. So that's all the emissions associated with heating, cooling, ventilating, running our spaces and the embodied carbon is sort of everything else. So it is the emissions associated with building our buildings, extracting those materials, manufacturing them, bringing them to the job site, constructing the building, replacing materials over time, and even where those materials go after we are done for them. So end of life and recycling, et cetera. I'm also going to use the word carbon is shorthand. So, and we can come back to this later on, but I know some folks get lost when we talk about embodied carbon, we are talking about all of those emissions, methanes, NOx, SOx, all the lobbies, but we need to bring them down to a single unit and global warming potential is a bit of a mouthful.

So sometimes I'll say, GWP, sometimes I'm just going to say, embodied carbon. So we are talking about all of those emissions associated with climate change. The very end of this intro to wrap it up is that another key term that I like to throw out there and folks are really thinking about, and this comes back to the way we set goals and the way some of these tools are oriented is really harnessing the sense of urgency are around embodied carbon. So you'll also hear people talk about the phrase upfront carbon. So upfront carbon or upfront emissions has to do with this huge burst and what is often a very, very large percentage of a total or a project's total lifecycle carbon, which is going to happen all the way at the beginning. So this is the emissions associated with all those building materials and construction itself. On this graph it's that big yellow bar over here, and these are all the emissions that are happening before anyone moves into the building, right?

So this is just giving a sense, it's very different percentages based on the type of building. But you're generally going to have this huge burst of emissions that are happening all the way at the beginning. Then, each year you have your annual operational carbon, obviously, and then sometimes you're going to have these other bursts of say, replacing a roof, an envelope, swapping materials in and out, and then another little burst at the end, right? So when we're talking about total life carbon, we're looking at all of it. But sometimes we're also really interested in those critical emissions that are happening all the way at the beginning and are essential to reaching our 20, 30 goals. In this really critical moment of time we need to draw down those emissions.

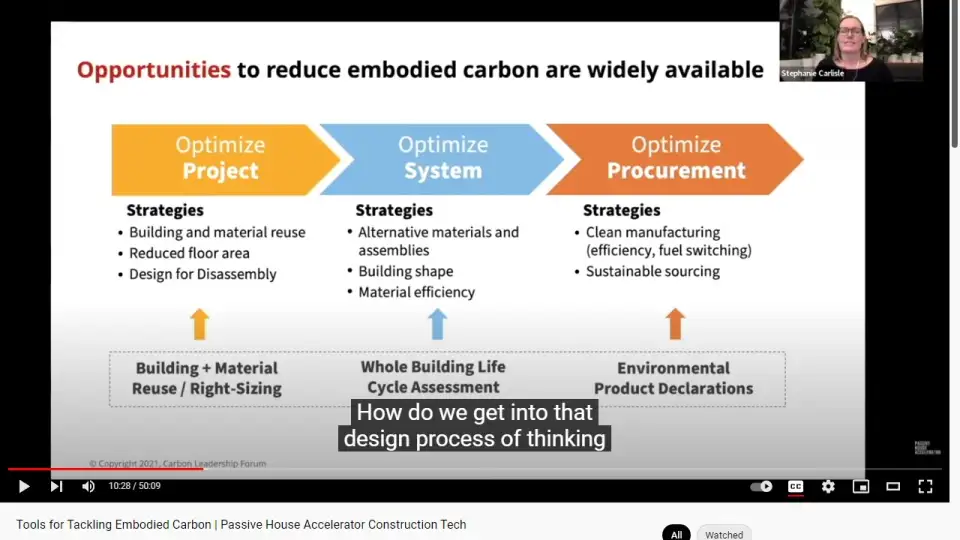

So very quick overview of the concept of upfront carbon as well. Of course, if you're designing net zero buildings or energy generated buildings, embodied carbon is what you get to work on because it's all that's left, right? So the embodied carbon of your project is probably nearly all of it. But luckily there are lots of opportunities for reducing embodied carbon on all of our projects, no matter what kind of project you're working on or building, what kind of building you're maintaining or renovating. There are strategies that start all the way in the beginning of pre-design through construction, and I want to talk about how we actually connect to and quantify these strategies, right? How do we get into that design process of thinking about trade offs and thinking about the value? So we're going to take a really broad view and I'm going to try to break down a couple of those different scenarios of how we look at optimizing the project? How are we building the right thing?

The strategies that go along with that say, building or material reuse, building a smaller building designed for disassembly. How do we optimize systems? So that would be thinking about different types of construction typologies, whether you're making use of advanced manufacturing or building with biomass, or a whole bunch of strategies there, or even just material efficiency itself and then strategies for optimizing procurement. So that's mostly the world of buying greener or lower carbon products specifically, and largely about driving clean manufacturing. So I'll pause there. That's the introduction. Hopefully everyone's come along with regrounded and what LCA is and what embodied carbon is. But we want to talk about really today get into the weeds are the actual tools and also explaining a little bit what's happening behind those tools. So I'm going to give you guys a crash course in LCA modeling, what it is, why we do it and how you can, and hopefully give you a little bit of a grounding, no matter what tool you end up using.

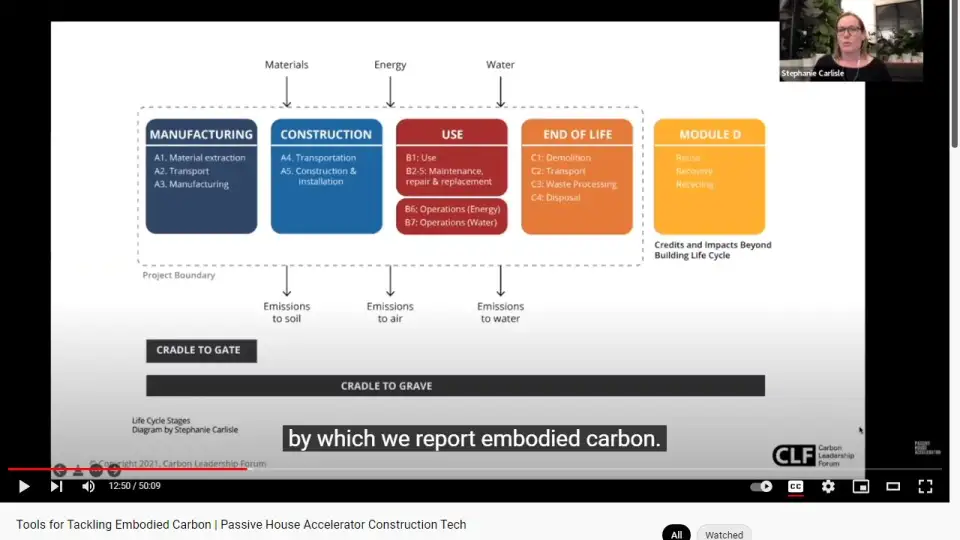

So I'm going to go more in the weeds than the tools typically wood, and hopefully you can kind of couch that back in sort of a theory of what LCA modeling actually is. So in order to measure, evaluate, and ultimately reduce the environmental impacts of our buildings, we have to know what they are. We need to measure them, right? We need to be able to evaluate them fairly. Otherwise, I always throw out there, I don't think most of us have very strong or very robust assumptions about how to decarbonize our buildings. So lifecycle assessment is a standardized methodology that we use to measure the environmental impacts of buildings or products or assemblies, ISO certified process and what it's going to do is track those, all of the inputs, outputs and potential environmental impacts of a product, material or a whole building through its whole life cycle. So all the way from that material manufacturing and extraction over here on the left, all the way to end of life.

Another way to look at that, this is just a diagram of those, the standards by which we report embodied carbon. So these are what we call Life Cycle Stages. So, and sometimes you'll just hear people use these as shorthand in terms of the numbers, someone's saying, "Oh, I'm just doing A1 through three," this is what they're talking about. So in our standardized reporting we'll break out manufacturing steps of material, extraction, transportation, and then the manufacturing itself. So that's say, smelting aluminum from bauxite, transporting it to smelter and then extruding it into an aluminum mullion that you're going to use on your project. So then we are transporting it to a site and thinking about all the construction processes in the use phase. We're thinking about replacement rates and repair or replacement, that also where you would bring in operational carbon.

So B6 and seven, then end of life, what happens to those materials? How do we collect them? How are we demoing the building? Or what might be getting retained or reused? Then, Module D, which is this happy, strange space of all that really, maybe you can think about it, if you're new to mod D as a lot of impacts that tied to circularity. So how might those building materials go into another use, right? So metals recycling, all sorts of other things end up in module D. Another big term you'll hear people use a lot, the sense of cradle to gate. So that just means we're looking at impacts from that initial extraction up to point of sale, so that's usually the gate. Very, very common when we're looking at environmental product declarations or products or cradle to grave, which is really the whole thing. So LCA ends up being, as I mentioned, kind of just a complicated or hard to manage input-output modeling system.

So you have all the materials, energy, water flowing into making those processes, and then we're going to calculate them, transform them. Talk a little more about that in a sec, and then measure the emissions to soil, air into water and report on a whole range of environmental impacts, not just carbon.

Some folks like to throw out this kind of picture that all you do is you're adding up all the stuff in your building, you're multiplying it by the environmental impacts per material and process, and voila you have your global warming, potentially your carbon footprint. This is true and not true, as a modeler I'm like, okay, but it's a little simplistic, right? It is conceptually okay. I will show you a scarier slide, which is a little bit, as someone who works on models and likes to build software, this is how I think of LCA models.

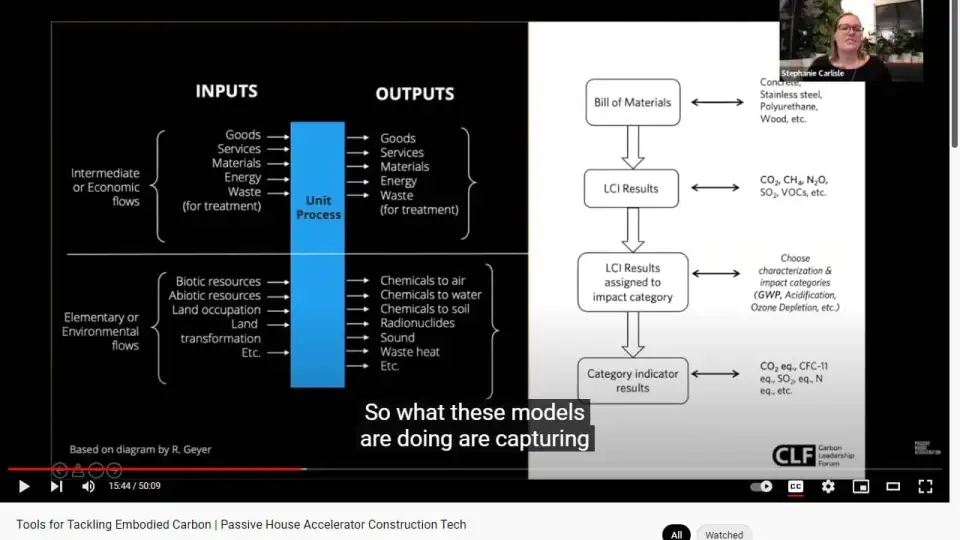

So don't get overwhelmed by the slide, sharing it with you, you can go back to it if you want. When I teach LCA modeling to my students, this is the kind of stuff we're looking at. So just want to show this mainly just to give the scope of what's happening behind the scenes. So what these models are doing are capturing all these different goods, services, energy, water, waste, treatments, all these different flows of how we use land, how we use biotic resources, et cetera, and again, translating that into all of these different chemicals and emissions. You look on the right, this might be hopefully helpful and not just overwhelming. What you're doing if you think from the perspective of a building is that we're getting all those different building materials. So I'll tend to call that a bill of materials, right? So how much concrete, stainless steel, polyurethane, wood, metals, all those different things.

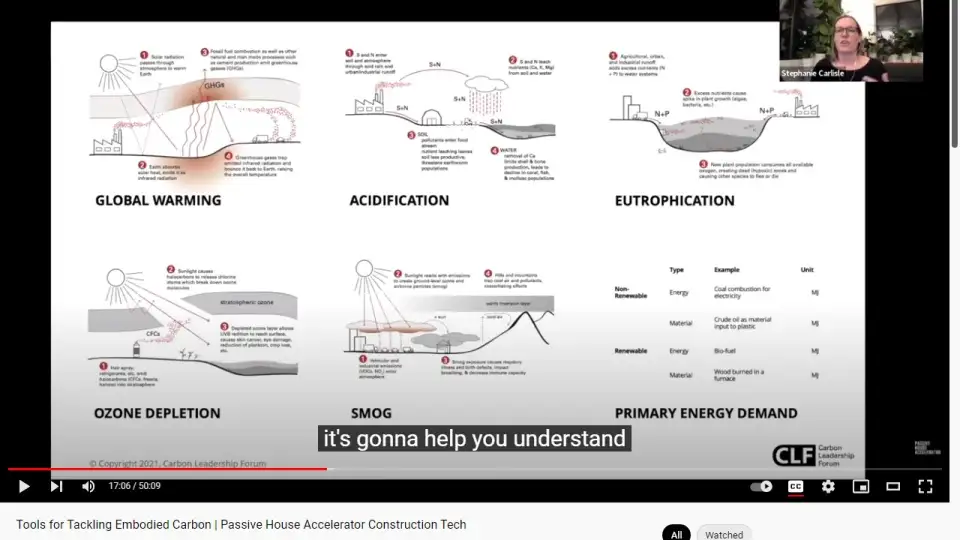

The software you're going to use in the model is going to translate that into those emissions. So it's happening on the left. So, but we don't just want a big list of chemicals, right? No one wants to know how much CH4 is coming out of their project. So then, what we're going to do is we're going to assign those chemicals to an impact category, and that could be global warming, that could be acidification, that could be eutrophication, so that would be water pollution, et cetera. Then, we're going to report those down here in an equivalent figure. So that's really how you get to this CO2 equivalent as a combination of all of those different chemicals.

I just wanted to make sure to touch on this because we all tend to be super focused on carbon, but LCA is, since it's such a robust modeling platform. It's going to help you understand all these different trade offs that pop up of, one of these materials might be really low carbon, but maybe it has other environmental impacts that I want to wrap my head around. So I just want to take a moment just to point that out and we can come back to that later.

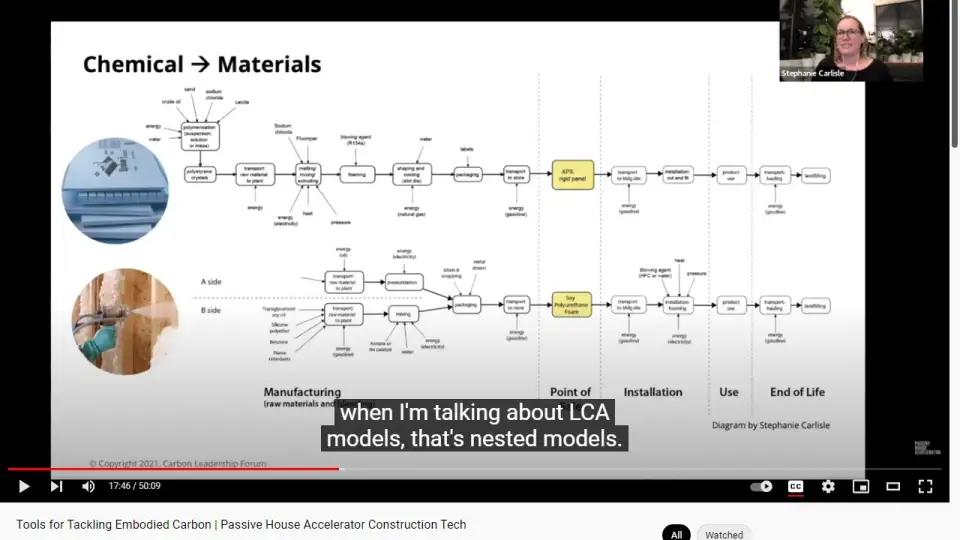

So one thing that's very cool about LCA models is that you get to learn how everything is made, which is awesome and very interesting. One thing that is very challenging about LCA models is that you have to know how everything is made, and hopefully your software and your tools are going to help you with that. So just want to give you this little snapshot of what I mean when I'm talking about LCA models as nested models. So if we're zooming in and we're looking at here, this is just a diagram of some models that I built. They're not the kind of models you would probably be playing with, but this is all the way back at the material stage. So this is just two insulation products, XPS, rigid panel, and a soy polyurethane foam.

So this is showing just at that cradle to grave perspective broken up by lifecycle stages. Just pointing out that within this different model, the inputs and outputs are going to go all the way back to the initial chemistry, right? So what are all of the different... How are we making those polystyrene crystals? What are all the chemicals that are coming together every time that there's a blowing agent used or heat or water or pressure? There's all sorts of processes going on. But we're also going to think about what's happening on site, right? Because if I'm buying a rigid foam panel and I want to connect it or compare it to something that is installed on site, like a soy polyurethane foam. I got to think about all those blowing agents and foams that are going on say, in the building, not in the factory, right? So the LCA model's going to help you put all that stuff together, but we can't look at every material at this resolution, like we would go totally insane.

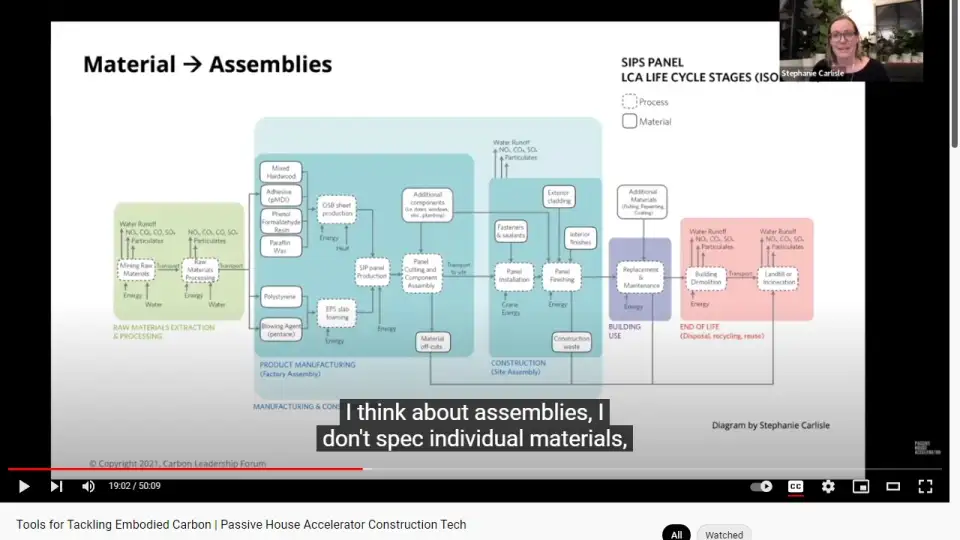

So we tend to think about assemblies, as a designer I think about assemblies, I don't spec individual materials, and I certainly don't spec chemicals. So the next step in what's happening besides LCA tools or within them is that the tools themselves on helping to combine all these materials together. So this is a diagram of a SIPs panel and what's happening here is you're... Oh, okay. This is again, broken up into life cycle stages. So we're seeing those raw materials coming into that process. We're seeing the wood, the adhesives, the resin, the waxes coming together to make a sheet of OSB. You look at your EPS foam coming in, you have all the processes. Then we have processes waste off cuts, things that are happening on site. We might think about replacement or recycling or waste disposal of all of that through construction and building use.

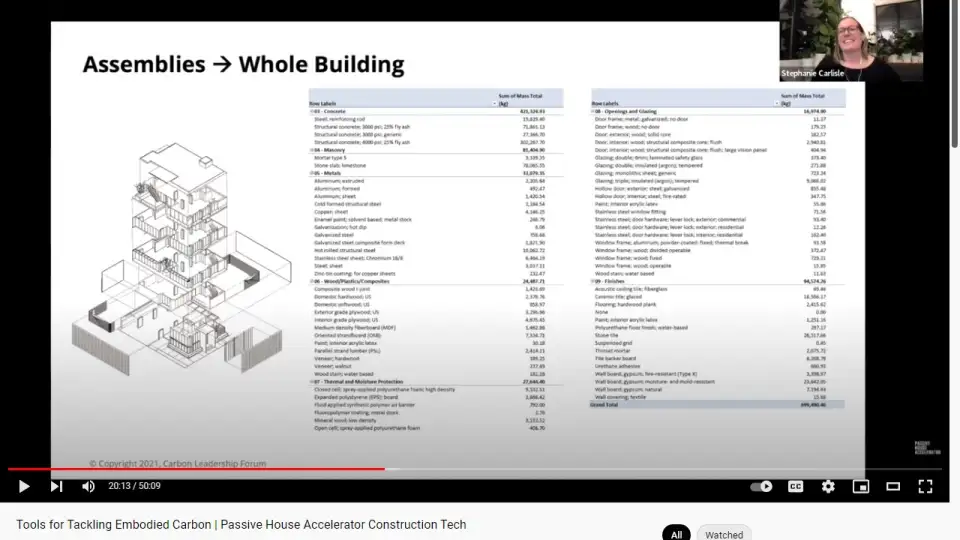

Then, there's all different emissions or chemicals that we're tracking at end of life. So that would be an assembly view where we're bringing multiple materials together, and then we bring that into a whole building view, right? So by the time you get to even a pretty simple building, a residential project or a project of any complexity, you're going to have lots and lots and lots of materials, right? So I think you can get the sense now that to some degree, what a lot of the LCA tools are really doing is helping with all this complicated accounting. The last step is that there are also folks who are really interested and excited thinking about beyond the single building. So thinking about all different development typologies, about urbanism, about planning and trying to understand how to zoom out yet farther to think about say, hold communities or neighborhoods.

So if we zoom out from that introduction, what this really means is that what LCA tools are doing fundamentally is bringing together two different types of information and two different types of complexity. So on one hand, and the type of tool you use will balance this differently. On one hand, we have all this information about manufacturing, about how materials are made that are being brought into our tools. Then, on the right hand side, we have lots of information that sometimes we're supplying, because we know this about our projects, right? About how materials actually get put together, right? What is the design of your building? So the tools that we want to use are going to help us manage all of that, all those pieces of information and do it in a way that is reasonable during our project. So that is your crash course in what is happening behind LCA tools, and how they are used to manage report and give us information about environmental impacts.

So the big question I think most of us have, and when folks start really getting into this process is how do I actually do this, right? Which tools should I use and which ones are going to make self for my process? This seems super complicated and you might be a little overwhelmed. So the way I like to break it down is essentially you need to pick the tool that works for you, right? All of your projects are different, right?

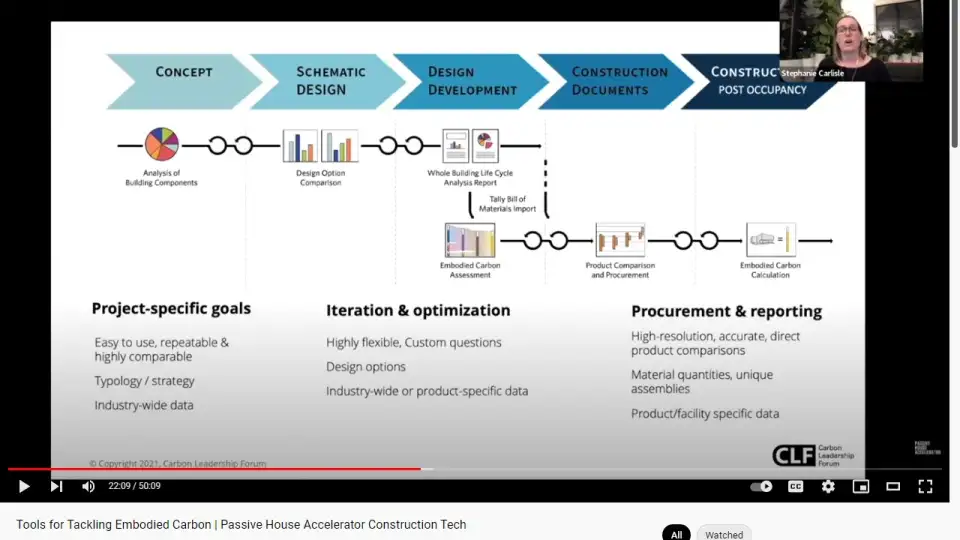

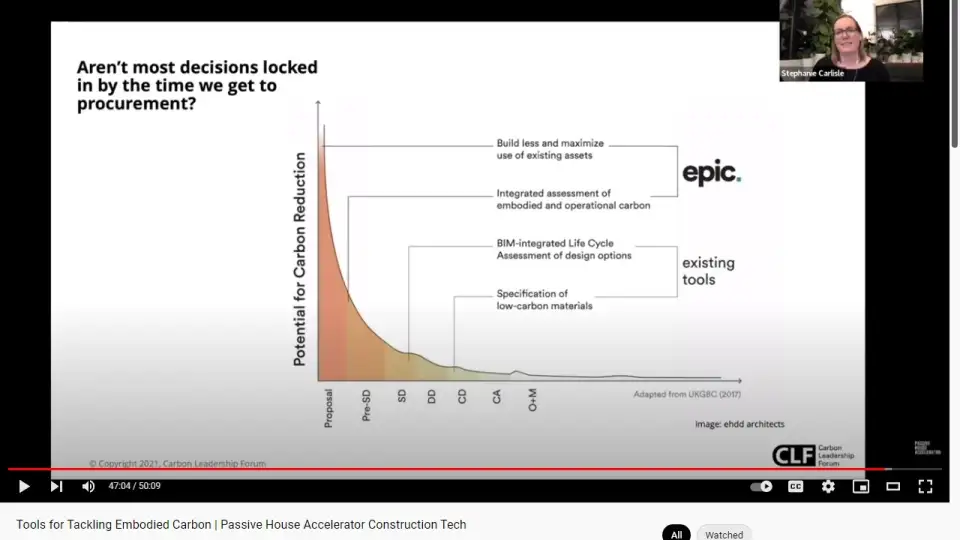

So I like to think about what's starting to happen is that similarly to energy modeling or building documentation is that we're all using lots and lots and lots of different workflows, and analysis can be helpful at different stages of a project. So this is just a general sense way that I like to think about it is that early on during concept development or schematic design, you probably want tools that are easier to use, that are lighter weight, that are going to help you... Are going to be based on typologies.

You don't want every chemical and every screw and every piece of adhesive, you don't want to have to give information you don't know about your project, right? So this is the world of calculators. This is the world of easy to use lightweight tools that luckily there's a bunch of new ones in development. When you're using LCA during design development or even into CDs, that's when you want tools that are higher res that are really going to be highly flexible and they're going to actually answer the design decisions that you have, right? So if your tool can't model the scenarios that you're really weighing, it's not going to give you very helpful information, right? Then, we have a whole other suite of tools that happen later, or really great later in the design process. So these are tools for benchmarking, for procurement, for picking specific products, and those are often going to go all the way down to individual products or unique assemblies, or might even have say, different information about concrete batch plants, right? Where do I actually buy my aggregate? Where do I get X, Y, Z material?

So hopefully this gives another little sense of, where do you fall at this stage? What it means is that probably if you really get into using LCA tools or making use of this kind of analysis data, you'll probably use more than one tool, right? So what's very, very exciting is that in the last... I've been doing LCA modeling for about a decade, and 10 years ago, there was almost nothing out there at all. We were using spreadsheets, it was bad news, right? So, and there was amazing work going on that was really, really early tools. Some of which are still around, which is awesome, and what's happened is that we've had this huge, especially in the last three or four years, this huge diversity of tools coming online. So hopefully what's going on is that we're just getting to a space where the practice of LCA gets more and more accessible and more applicable to projects.

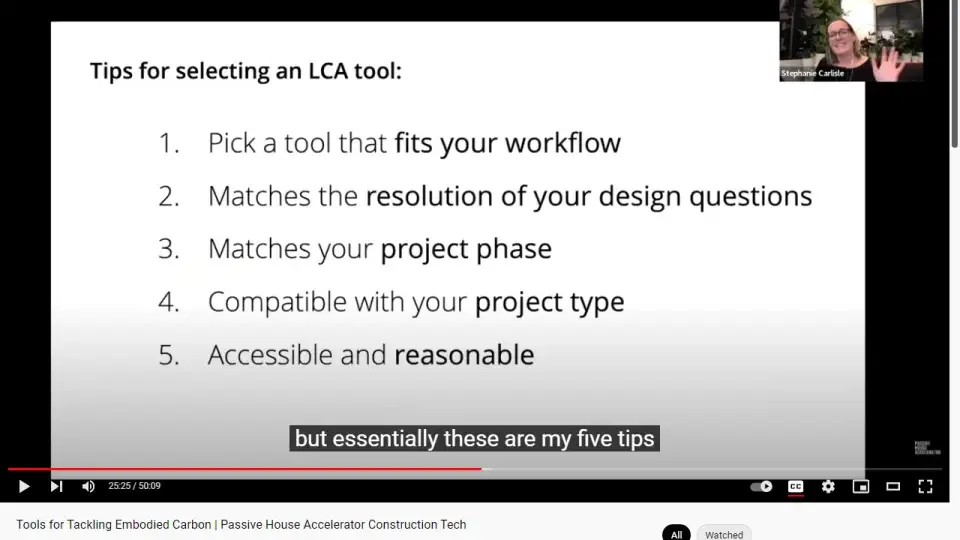

So what I would like to do is walk through four or five tools, and I think they are tools that fit in really different places in this spectrum and they fit in different workflows. So what I'm hoping, and I'm not going to be able to talk about all of the tools. The CLF recently did a review of all of the existing or in development tools that we are aware of. We're hoping to publish a big resource, soon. We have almost 50 tools in that data set right now, and about half of them are in development, currently. So it's a really, really active space and it's a super exciting space. So I'm going to cut to the last slide. So when I run out of time, I will have already said this, but essentially these are my five tips for picking an LCA tool. That I want you to kind of keep in mind as I go through these.

So the first thing is that you want to pick a tool that fits your workflow. The first tool I'm going to show is a Revit based tool. If you don't work in Revit, it's not going to be that helpful, right? So hopefully, I think really what we need are more and more tools that can work with the way you are already designing your projects, right? That's what's going to make this workflow really possible and give you information on demand when you need it to make good decisions. So first of all, it's got to be a good fit for you. You really want to try to find a tool that matches the resolution of your design question that gets at that design phase, point I was just making a second ago. Sometimes that lines up with project phases and sometimes it doesn't, right?

So I'm going to use some shorthand of like, this is an early phase or an SD level tool, but this is very project specific, right? So take that with a grain of salt. It's more about the resolution and really what you're hoping to... What kind of questions you want to ask and what level of information. You need to really move forward under project. Some of these tools are more or less compatible with project type. So I bring that up particularly because there's a huge dearth of information on residential, particularly single family residential projects. So I'm going to show a few early phase tools that just are more geared towards larger commercial or institutional projects, and I think that's another thing to think about.

Then, finally you want a tool that is both accessible and reasonable. So we will come back to that at the end. But I think this is really, gets at this kind of question of having tools that just can fit within your workflow and ones that you can make sense of, ones that are not burdensome, but also are really empowering you to make decisions as a designer on your projects. Okay. So in general, most of what I'm showing are design integrated LCA tools. The main point, and I think, as I said, are that those tools are really helping to translate whether it's a design concept or a specific construction typology or a really, really bespoke assembly. They're taking that language that we use, the shorthand of how we often communicate design, which is not every single chemical, right? Every single weight of material, and what a lot of these tools are really... A lot of the work they're doing is that they're translating those, that design intent or that construction intent into discrete material, quantities and estimated impacts.

So they're going to carry that LCA data side or LCI data side, I'll just use those in interchangeably, and all the quantities. Most of us don't know exactly the weight of every building material and product in our buildings. You don't want to have to calculate, well, actually, if you're a builder, you probably know a heck of a lot more about that than I do as an architect, right? So there's also a little bit of gap at translation there too. But a lot of... That's a lot of the work that's happening behind these tools is translating the way we communicate design assemblies on the left to the actual quantities on the right, which is the only way you can really do robust input-output modeling, is to know what the materials actually are. Okay.

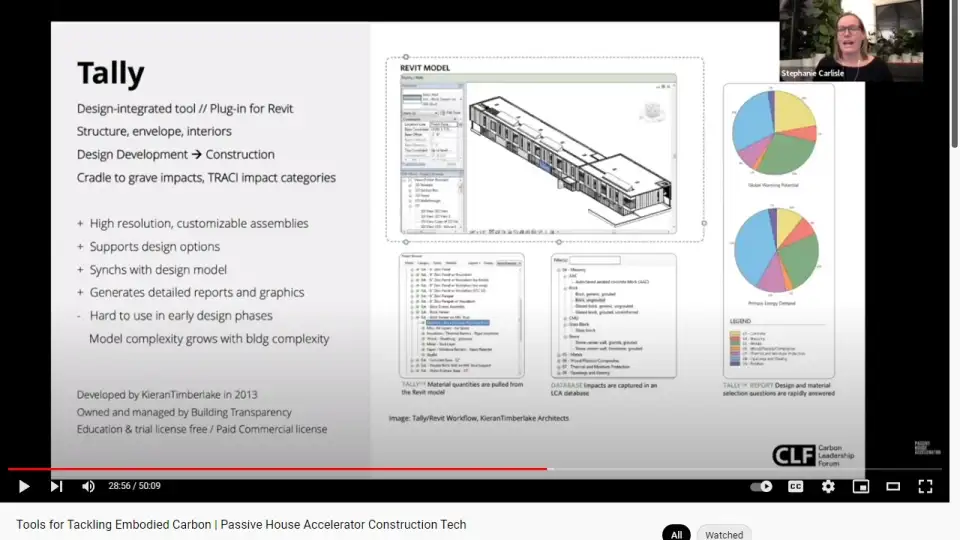

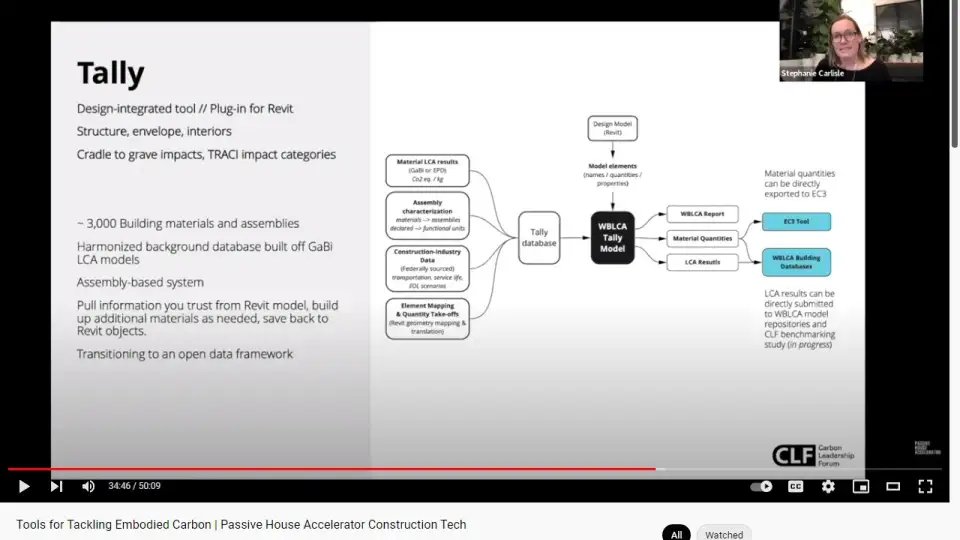

So the first tool I'm going to talk about is Tally. This is one of the most popular LCA tools. It's also one I know super well because I worked on it for a long time. So I'll start there because for some folks, this might be the first tool you hear about. It's an interesting reference for kind of how that process works. So I'll use this as an example, Tally is a design integrated tool. It's a plugin for Revit. So like I said, it works natively within that design software. It's going to be able to calculate impacts for a whole range of building components, not every tool will do that. So work on structure, envelope, interiors, a whole bunch of accessory materials, et cetera. It's not going to do furniture, right? It doesn't do landscape. So there's a bunch of gaps, but it's a pretty robust system. There are some tools like say, Beacon or others that are also Revit integrated, but just do structure, right? So they're really just going to either do primary structure or maybe a little envelope.

So Tally will have a bigger scope and most people tend to use it when you have a pretty robust model. So I'd say, this is a mid to late design phase tool to be fair. There's plenty of folks who use it in pre-design, but you got to do a lot of work to make that happen. It's going to show the full cradle degrade impacts, and it's going to show all the impact categories. So starting with a really robustful, whole building LCA tool. What Tally is going to do as a little bit of how I was describing [inaudible 00:30:08] in general. So it's going to reach into your Revit model and it's going to try to understand, what information do I trust in that model? What information can I pull from that model? How do I supplement it with information? You are going to tell it in order to really assign material more accurately, right? Because that's not what we use Revit models for.

So what's really nice about the tool also is that it's really good for optioning. So it's going to let you run your analysis right in your design options, which can be extraordinarily helpful if you're using design options and work sets. The other big attribute that folks like about it is that you are making those material assignments and they live parametrically in the model. So for example, if you're assigning a wall type and then over time that wall gets bigger, it gets smaller, you have different quantities. It's going to keep updating all of that. So you don't have to do that thing where you stop designing, you do all your manual takeoffs, you've run an LCA model, you hire a consultant and pay them tons of money, and then you get the results back six months later and now your building is completely different.

So a little bit of a caricature, but we've all had those moments, right? So the design integrated nature was what this project was really all about. Some cons and things that are negative. As I said already, if you don't use Revit, this is not the tool for you. It can be hard to use an early design phases and there's a bit of a learning curve, right? So this one takes quite a time investment, and I think it's often really well suited for folks who know a lot about the project. So it's kind of hard for consultants to come in who maybe don't know all the details. Although I think plenty of people use it that way, but I'm just putting it out there. It's really aimed for the actual folks who know those components the best.

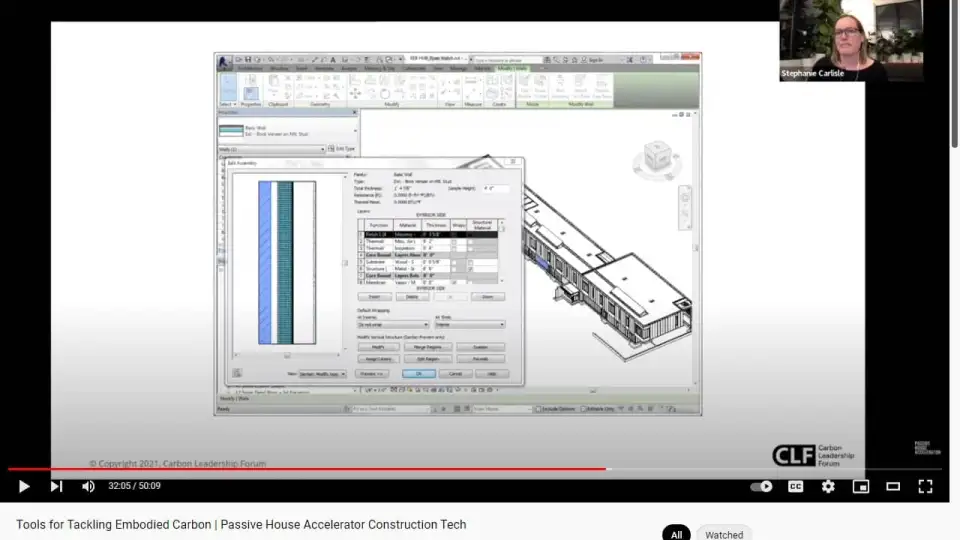

Okay. So to very quickly kind of give this sense again, because this also carries through to some of the other Revit integrated or BIM integrated tools. It's going to kind of pull information, for example, this is showing what Revit would know about a certain wall assembly. It's kind of labeled. It kind of has some thicknesses. These materials are not solid. We don't necessarily know what all these things are. So the Tally interface is going to help you translate those assemblies or components into material quantity. So it's going to ask you all these other questions. What is the spacing of your wood studs? What is the type of mortar you're using? What is the density of nails, right? All of these different attributes that might be in your specifications, and it's going to use that to translate into [inaudible 00:32:50] quantities. It's also going to let you put in all sorts of information about replacement rates, which is really useful.

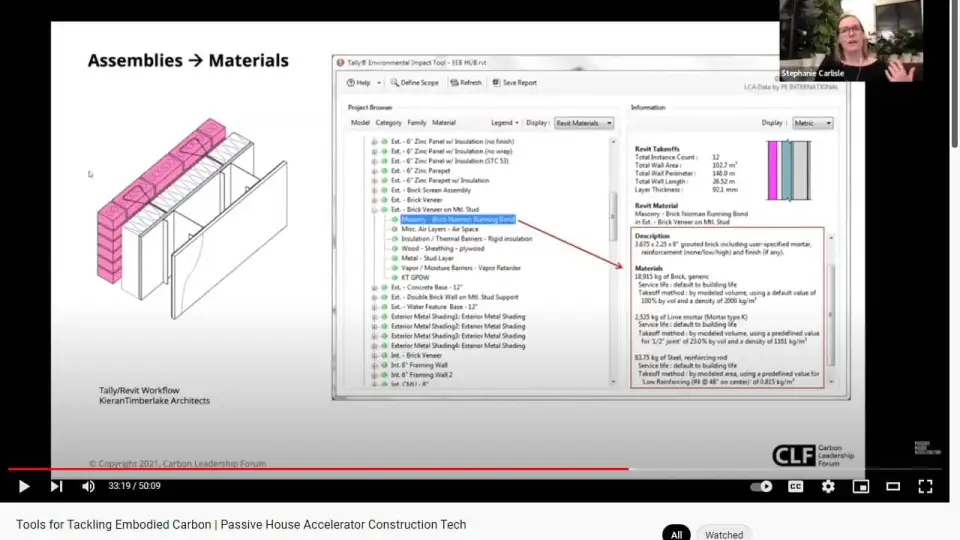

So I'm going pretty quickly. So I'll just keep going. But essentially this is showing a whole bunch of different assemblies and wall types that are pulled right out of that Revit model. Then, once you've assigned materials, you can see that it's turning into actual quantities in kilograms of all of those sub components. We model the mortar in that masonry wall, but we know that it's part of that assembly, for example, or we didn't model any of the steel reinforcing rod and now I have accurate quantities at steel.

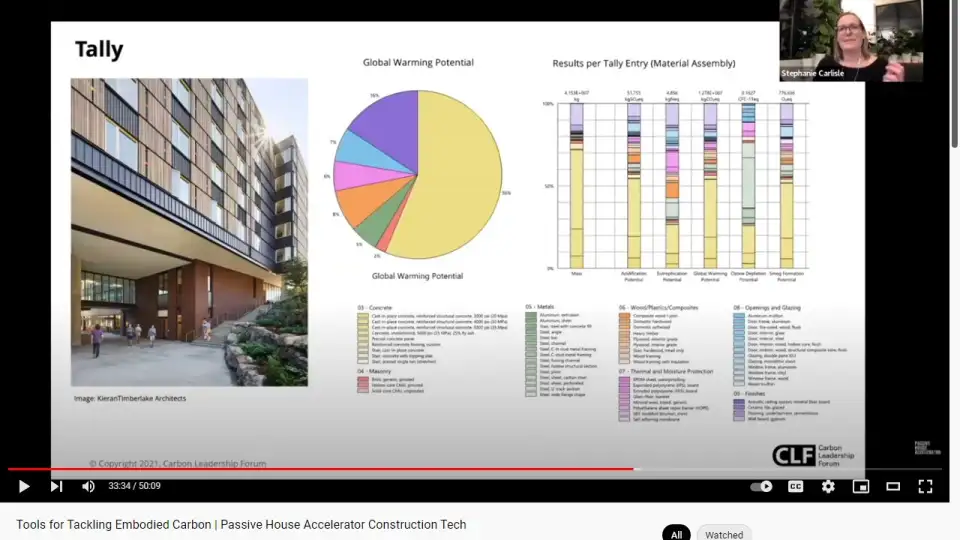

Then, what the tool ends up giving you is this very high resolution view of your project. So you can break out environmental impacts by material, by component, by work set. There are a lot of pie charts and there are a lot of stack graphs, but what it's going to let you do this graph over here on the right is you'll see these in lots of the different tools, they're called a contribution assessment. So it's helping you pinpoint right away for global warming. What are the biggest hitters? So you can see yellow, this is now colored by master spec division. So you're seeing all of [inaudible 00:34:00]. We can start to understand where are these different components and how do I start making design decisions to change them. It does design optioning, as I mentioned. So this is just a really simple optioning exercise where I duplicated the building geometry, and then made changes to the concrete specification. We're able to not just say, obviously using a lower cement mix is better and would have a lower carbon impact, but what is the actual reduction on this project? How does that trickle through? So very, very fast assessment to run. Okay. I got to go quickly. So just highlighting a little bit about the data and some of the pros and cons.

So it's lots and lots of building materials as it really harmonize data set. It's based on assemblies. So if there's a really you want, but it has some shortcomings. So there's a real shortage right now in bio-based materials, and if there's a material that's not in the data set, you can't readily add it, right? So hopefully they're going to grow over time, but you could not use Tally right now to measure or model a hempcrete wall very well. So there's mostly, well, a lot of the shortcomings are really materially based, and it's in the process since it transferred to ownership by building transparency of moving into an open data framework, which is super exciting.

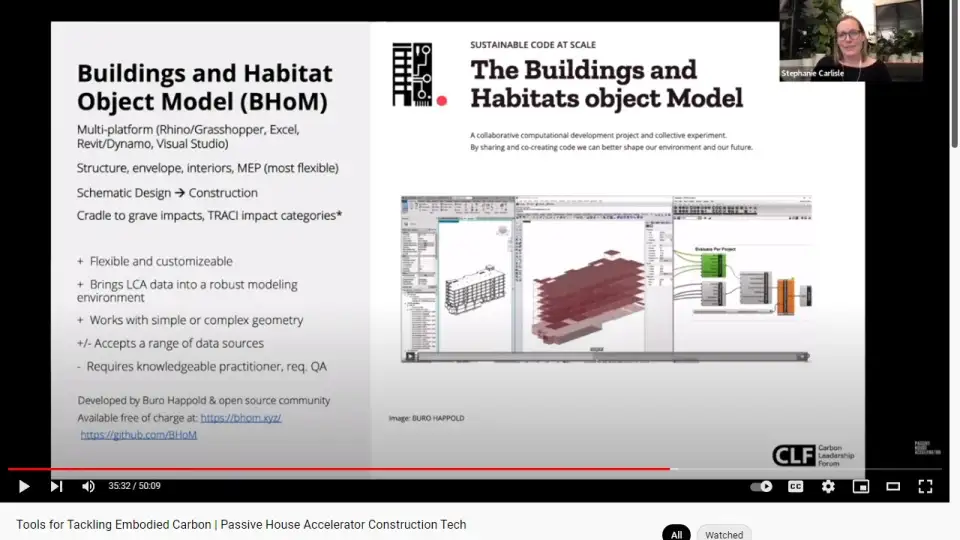

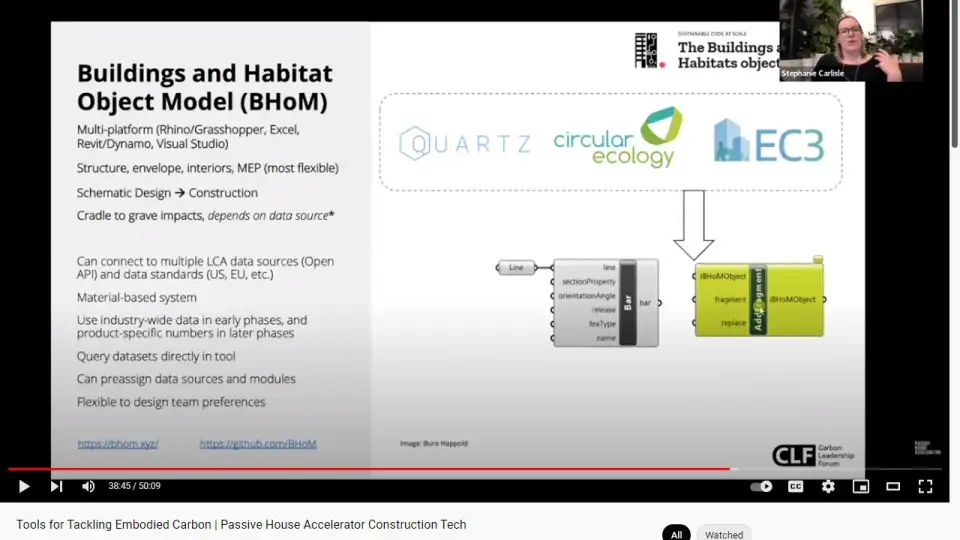

Okay. Second tool I want to talk about it's called BHoM. This is the Buildings and Habitat object Model. It's a tool that I really love. For the nerdiest folks out there, I think you will love it. If you are a Grasshopper or a Dynamo scripting nerd, I think this is probably one of the most complicated tools that I have used in LCA, but it's also super powerful. So I thought it was at least worth giving a head nod to it, but I won't go into as much detail with each other tools. So BHoM is a multi platform tool. So it would help people working on complex projects move between, it was originally designed for energy modeling and all sorts of other analysis, and then this tool developer group built a LCA module into BHoM, which is super, super awesome. So it allow folks to move between Rhino and Revit and IES and Excel, and all sorts of other cool stuff. If you don't know what those platforms are, don't worry about it. You're not doing a ton of energy, that kind of energy modeling. I don't either. So it's hyperflexible and it's going to fill some of those gaps. So it'll do structure envelope, interiors.

People are doing a lot of work on MEP in this tool, which is really, really cool and building out mechanical systems. As I mentioned, it's an open source project, and so it was initially developed by Buro Happold, but there is a whole world of developers out there that are building in new modules and data into this tool, which is very cool. So it's only going to get better over time. It's very flexible and customizable. It works with really simple geometry. So you can just do massing models and assign materials to them, but it also works on crazy complicated buildings. So it is like, really depends on how you want to use it. But it requires a pretty knowledgeable practitioner and you need to be able to QA these models. But basically what BHoM is going to do is that it is going to connect the geometry in the model, assign materials to it, and then pull the LCA data or the LCI data from an open source data set.

So what's also cool is that this can use, Tally is only North America data and BHoM was developed to connect the dataset from all over the world. So you can use it on projects all over the place for any of our friends out there who are not in North America, which is also very, very exciting. If you're a Grasshopper person or a Visual scripting person, this will make sense to you. This tool is going to do everything from help you set the scope of the analysis, connect, enter in all sorts of project information, build out geometry, build out different takeoffs. Similarly to Tally, it's going to help the modelers set what information they're pulling from the model. So for example, if you're doing MEP study and you might say, okay, all of this different geometry is duct work, but I just want you to take the lights and I'm going to give you the sizing, or this is all the sprinkler pipe, we're going to use these defaults, et cetera, et cetera. It also does data visualization and all sorts of really other cool sources of analysis. My students love this because they work in Rhino. So it's a really interesting tool for them, and it also does all sorts of dynamic charts, et cetera.

So what's really exciting about BHoM is that... Wow. That's really fast. That data interface, where the tool is actually also going to let you query data sets natively in the modeling environment, which is really awesome. I don't know of any other tools that do that right now. So it is a material based system though. So these data sets are going to let you pull different types of concrete, different types of steel, different types of foam, et cetera. You have to make sure as a modeler, that all of those assumptions that translated into an assembly are accurate and correct. So there's a lot that you can do to play with this tool, and I put some links down here for where you can learn more about BHoM platform in general, and then everything is really well documented on their GitHub repository. Kayleigh Houde is the main developer. If you want to get in touch with her, she is a genius. She's awesome.

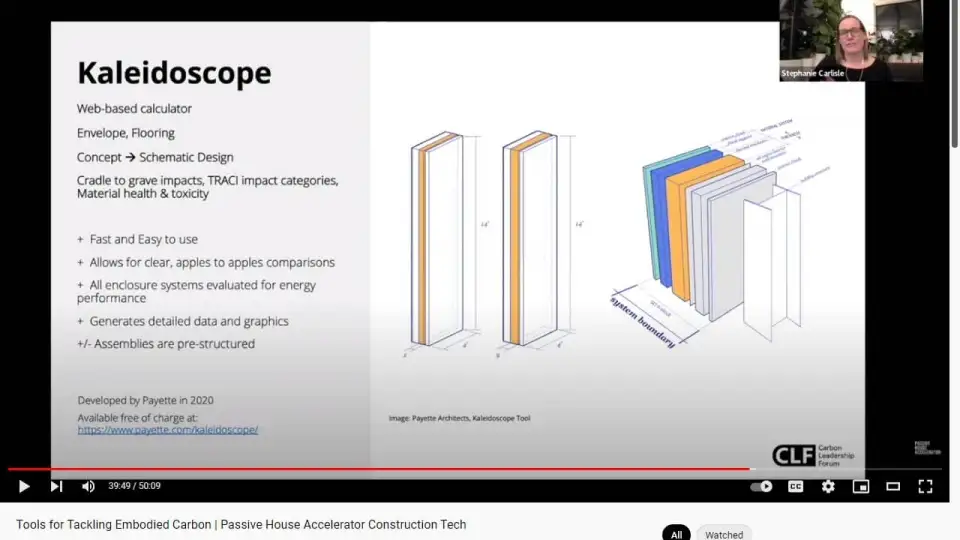

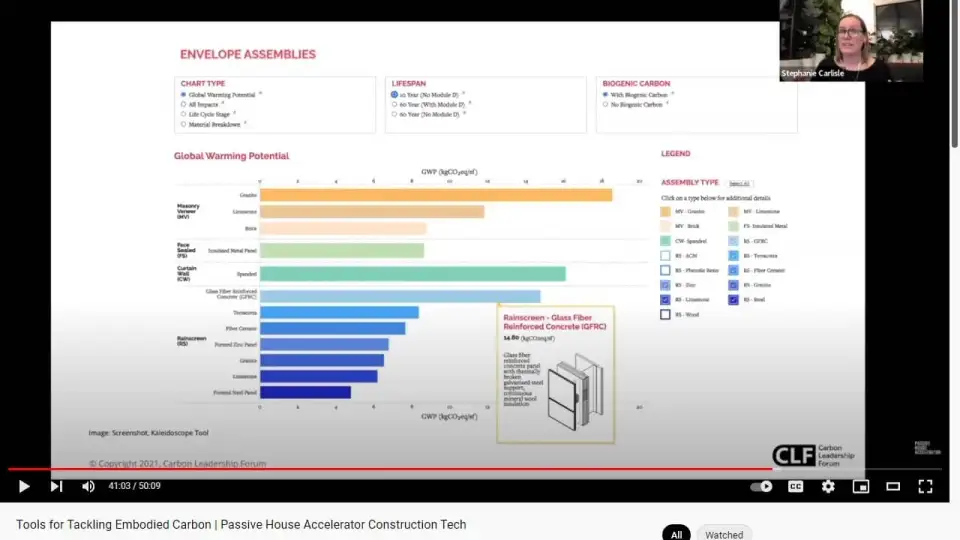

Third tool I wanted to show is totally different, right? So if the flashing screen of Grasshopper scripting was a little overwhelming, Kaleidoscope is a typology based tool. So this is a free to use web based calculator. This tool aims to give people information all the way much, much, much earlier in design process and is really good at targeted LCA studies. So it just looks at... Right now, they've built modules for envelope comparisons and for flooring. It's mostly aimed at concept, schematic design, but frankly, lots of people use as far later into design when they're still looking at different optioning. It's really fast. It's easy to use. You don't have to know any technical knowledge about LCA, a little bit about how to interpret the data. So I would really encourage any team to check this tool out. What's also nice is they've done the hard work of building up all the different wall assemblies or envelope options, running them through thermal models, evaluating them for building performance, and what you then get to see is all of the environmental impacts associated with that as well. So this is a screenshot of what the tool looks like. So you can quickly pick a different types of assemblies.

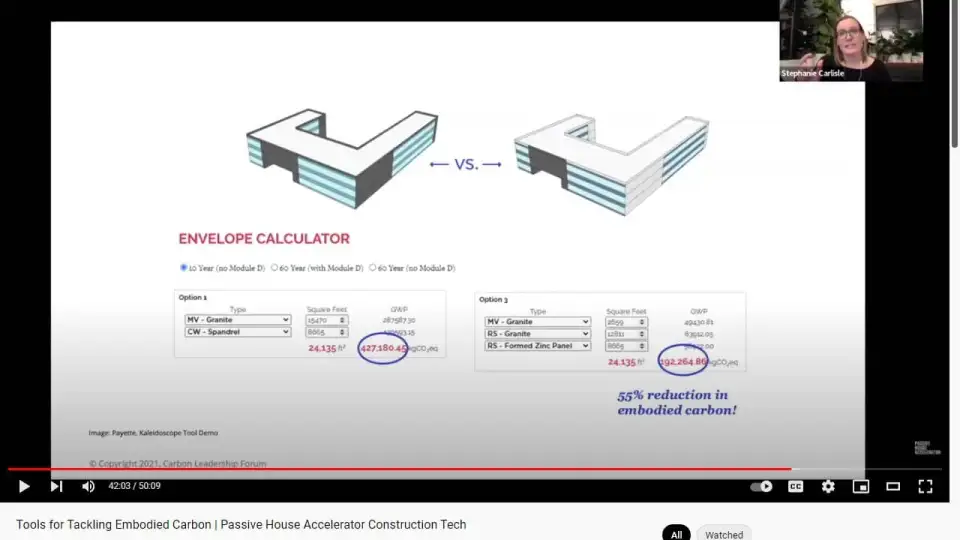

So this is showing different masonry veneer walls, curtain wall assemblies, or rainscreen. These are just typical as tight. So this is a typology approach. You can't model anything hyper specific in this tool, which is why we're calling it a concept level or schematic design level. But if you want to give a team an understanding of, hey, if we flip half of this terracotta rainscreen over to this type and we have 60% of the wall this type. What it is going to let you do is build up those scenarios across the whole building, and then it's going to show you the data in lots of really interesting ways. So this is a graph showing it broken down by life cycle stages. It'll get into the detailing assumptions of these walls. So I also find it a really great educational tool where you can look into the assembly and say, "Hey, which components of this wall actually are the biggest contributor to global warming? Where are my hotspots?" Right? I don't need to do all of that modeling, it was already done and QA-ed, and it's really great data. So this is a really cool tool to check out, and then it'll do these quick calculations.

So this is looking at two different design options, and it'll give very specific quantification of the potential reduction between those design options. So really great tool to use on a project. So as I mentioned, it really just has these specific typologies. So you can't model a whole building in Kaleidoscope, and right now it mainly focuses on... Oh, sorry, it will do either upfront carbon or the full life cycle, and it's going to break it out a lot of different ways. The last thing that's cool is it's also going to give you information about material health, which is great. So I'm always looking out for tools that bring together embodied carbon or operational carbon, and also start to bring out some of these other environmental concerns.

So I think that's something that's really interesting about this tool and where the team at Payette, who developed this tool and then made it open source, was able to also bring together to their material health team and help look at those different ways of evaluating materials together, which is always super helpful. The fourth tool I want to share is also a free open source project.

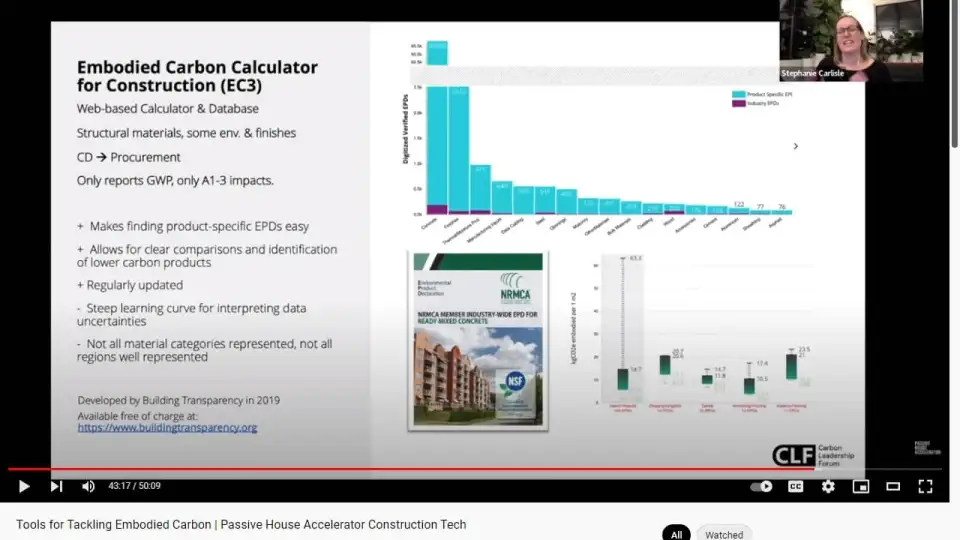

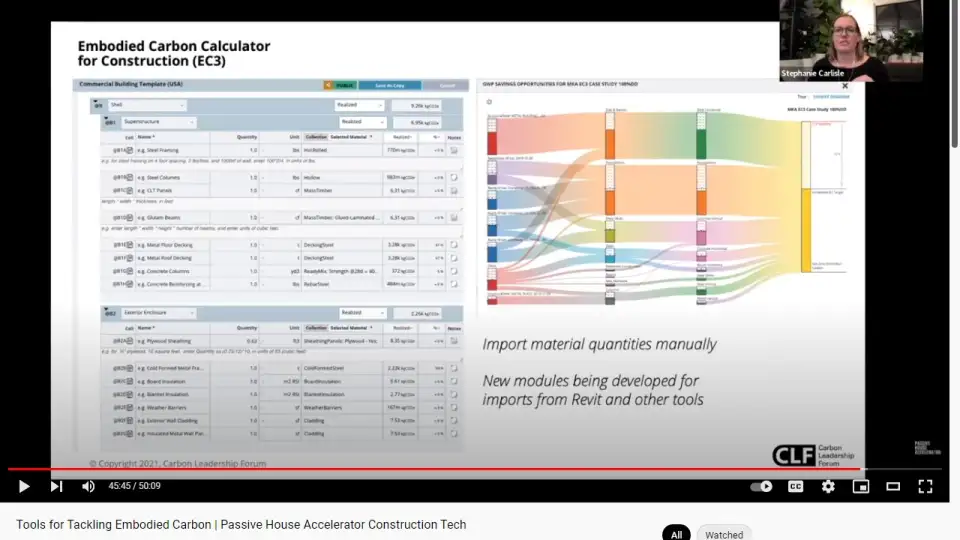

This is the Embodied Carbon Calculator for Construction. Most of us just call it EC3. This is a totally different type of tool as well. So this tool is for procurement. So it's just about building products and materials. It is a web-based calculator and a database. The database is rapidly growing. So right now it's mostly structural materials, but they're building up new categories all the time over at building transparency. It only reports GWP. So it does not do whole building LCA. It doesn't do whole life LCA.

It's only a one through three impacts, and that's because it is a database of environmental product declarations. So what this team has done is they have digitized and downloaded all of these different environmental product declarations, little LCA reports. They've taken the carbon, the global warming potential data, they've actually dropped the rest. I think they will add in those impacts at a later date, but this is very, very much under development. Then, what they're going to help you do is compare the different products that are available. So this is really about specifications and procurement. A lot of contractors use this tool, more and more designers are using it. What we used to have to do is go on product manufacturer websites, download all these terrible PDFs, seek them out, get them from reps. It's really, really helpful that EC3 brings all of that documentation together.

So it's a really helpful transparency tool, and that it's going to help you identify low carbon products. So just because a product has an EPD does not mean it's a low carbon product, but it's going to give you some of that data that has been declared and it is regularly updated. But it can be a little bit hard to wrap your head around how to use this tool the first time. So I think honestly it has a little bit of a learning curve for how to read all the data. If you're used to doing specifications and looking up product information, the way it's organized will make a lot of sense to you. So you can kind to navigate to material, it's kind of master speccy, but not totally master spec. So you would navigate to a category. You can filter by performance attributes.

So this is showing cast in place concrete. So you can set your strength, your cure time, you can set some other information, region and what's going to then show you is all of the different product specific EPDs and that it's going to show you that variability. The idea then is that you can start to understand where there's opportunities for reduction, and I think this 80/20th percentile is super important for folks who want to start putting some of those numbers in their spec and say, "What is achievable?" Is there one product that meets that spec? Is there 50? What's actually out there in the market? So I would say this is a great tool to get involved in. It's growing all the time. It's moving towards digital EPDs. But the short sites right now is that you can't do whole building LCA with this tool, because it's just a one through three. Not every category is represented, although it's growing a lot and the numbers can change because it's really constantly, it's a pretty dynamic tool.

So just be careful if you're searching and comparing, the tool does not make sure that you are comparing products that have the same performance. That's really incumbent on the user to set those filters properly. So I'd say that's one kind of word of caution with this tool.

Then, the last two... Yikes. Want to show super, super quickly are two tools that are not available yet, but they're going to get released imminently that are early face assigned tools. The first one's called EPIC and the second is called CARE. So both of these tools are really asking this question of like, Hey, by the time I get to procurement, didn't all of these really, really high impact decisions already get locked in? I'm not suddenly deciding to do a mass timber building. I'm not suddenly moving to a new strategy. I've lost my window to do material reuse or argue for renovation. Where's the data for making those decisions?

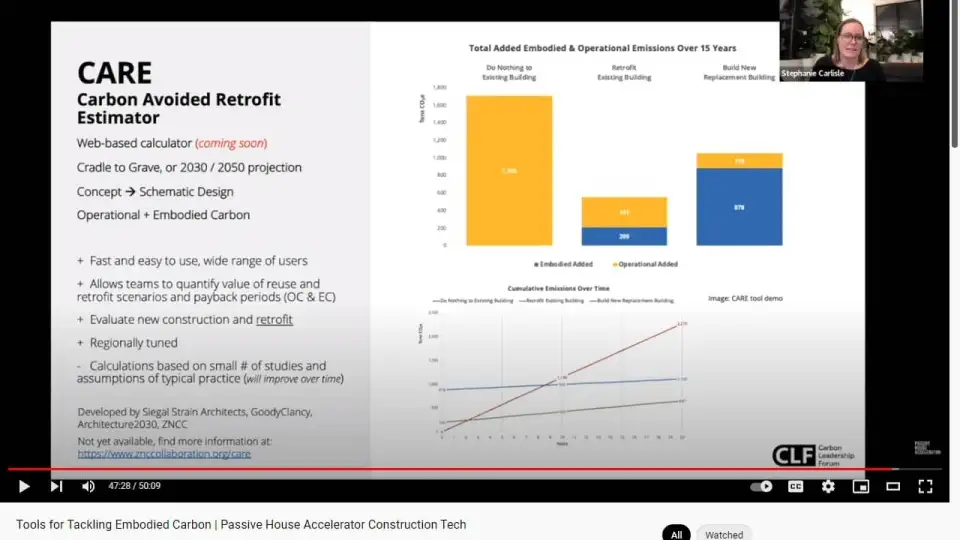

So what we're seeing right now is this kind of explosion of, or increased excitement about early phase tools that even work during concept development. So CARE is one that is going to get released very shortly. It's called the Carbon Avoided Retrofit Estimator, and it basically helps you answer the question of, does it make sense to do a retrofit or green energy retrofit of this building or to build new construction? So it's going to let you put in all different scenarios that are performance based for both the existing building that you're retrofitting or the new building to compare it to. Then, it's going to help you understand where is the point in time in which you've actually made back all of the embodied carbon that you've expended during construction, right? So do you not make that back for 30 years, for 20 years, for 10 years? When is that payback period? So I think it's a really interesting way of thinking about time and also talking about the value of historically reuse renovation and retrofit. This is being develop by Siegal Strain Architects, Goody Clancy, Architecture2030, and the Net Zero Construction Collaboration, I don't know what CC is. The historic building folks. They're very awesome.

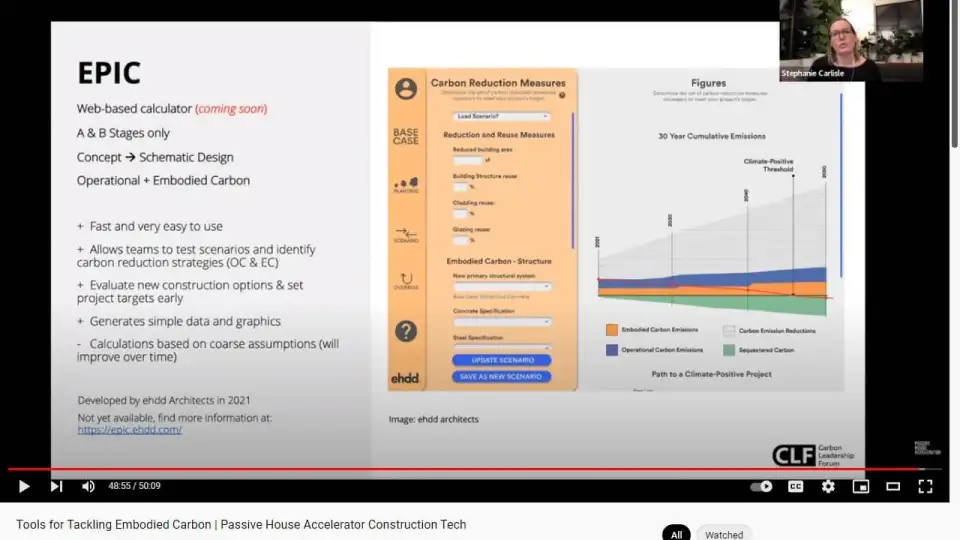

Then, the last one is EPIC, which is fairly similar and being developed by the folks at ehdd Architects. Also, going to be a web-based calculator, totally free of charge. This one also is going to take a total carbon perspective and it is going to... Oh, there we go. It's also going to allow you to put in design scenarios and this one is going to help folks really zoom in on looking at the embodied carbon emissions, operational carbon emissions. Interestingly, they also put in some different attributes for carbon sea frustration storage and energy production.

So they're going to bring together, these are some old screenshots. The tool looks different now and is hopefully going to go live next week. I'm super excited about it. I thought it would be live by this talk, but it's going to also again, kind of expand that scope to talk about all of these other elements and all these other strategies that we're thinking about from that total carbon perspective.