Doug Pruess (Owner at Midwest Efficiency Supply, AAMA Installation Masters Accredited Instructor) joined PHA Live! Construction Tech on June 8th to discuss best practices for incorporating high performance windows and doors into Passive House projects. His presentation covers misconceptions, field problems and solutions, key questions to ask, and the mission critical aspects of ensuring a successful install.

Read the transcript below for the video!

Marina Pickering:

We're really excited to be the sponsor this week, not just because we like being involved with Passive House Accelerator, but because it's Doug and Doug is one of our alumnus from our training program and anybody who has worked in passive long enough knows that the conversation always comes back to windows, right? And the biggest bottleneck or thing that professionals get stuck talking about a lot is window installation. So lots of questions around that subject, which is why it's always super exciting for us when, in our trades class, we've got people who are already experts in the field in a particular thing. So it was so nice having Doug in our bootcamp last February, because he really challenged and asked questions and harped on Enrico about all those geeky window questions and it spurred a lot of really great conversation in class. So I'm looking forward to seeing what he's going to present about today and I will turn it over to Mr. Doug for this wonderful presentation on window geeking.

Doug Pruess:

I appreciate that. That was a fantastic class also. I learned a lot. What was great about being in that class is that when I argued windows, most people will sit around and listen and maybe shrug shoulders, and I got a lot of feedback back and forth. So I appreciated that argument back and forth. And while I like working with Passive House consultants and the passive community, obviously as we all know, not all projects are passive. Not all projects are even high efficiency, but maybe bringing some of those thoughts and ideas into everyday installs or even trying to go above and beyond and create methods during installation. And I guess I can't stress it enough, I might say it a few times here, of getting everybody involved. Something that an installer's doing is going to be... An installer's trying to make what is written on the piece of paper, what is drawn out and then trying to take the real world scenario and trying to put paper into the field. And that's a rough thing and I have a few rules, things like that we can just go from there.

All right, everybody can see that? Good deal.

So, I've been doing this for a while. Actually, my uncle was a contractor when I was in high school. And then, when I went to college, that was my part-time jobs, working for a builder, all that kind of stuff. And we eventually moved to Northern Illinois and I started just installing windows full-time because nobody really needed the degree that I had. Being pre-veterinary in an area like this doesn't really work too well. So I just got out of the house, started doing installations like I did in college, and then just went from there.

And the reason for the certifications, this is just a handful of them, is that, when I was selling my first jobs, when I was in my late twenties, I was losing out on projects because basically telling me, you're too young or inexperienced or things like that. And I noticed that people that were in the field for 40, 50 years weren't even doing it right. And they're just standing on the precedence of, "I've been doing it for a long time, so I've been doing it right for a long time." And that just didn't work. So a friend of mine that was a rep for a window manufacturer told me to go get a certification. So I went and got the AAMA Installation Master Certification. I wasn't an instructor at first, by no means. And then through that, I ran into people like Mark and high efficiency architects and started learning different things of how to test homes and bringing that into windows. So that's where that is.

Let's see, moving on. I'm breaking this all down into the product way, I would say is just specify and identify the right windows for the project or the right product for the project. And there is no one perfect window out there. I've heard many a times where someone will ask me, "What's the best window?" There's no such thing. A high efficiency passive house window doesn't make sense in say your standard home. And if they didn't pay attention to the insulation in the attic, that kind of thing, it's just, you can't with a straight face and in a right mind, say, "Yes, put triple pane windows in this house when there's four inches of insulation in the attic. It just doesn't make any sense scientifically. So just going down that road.

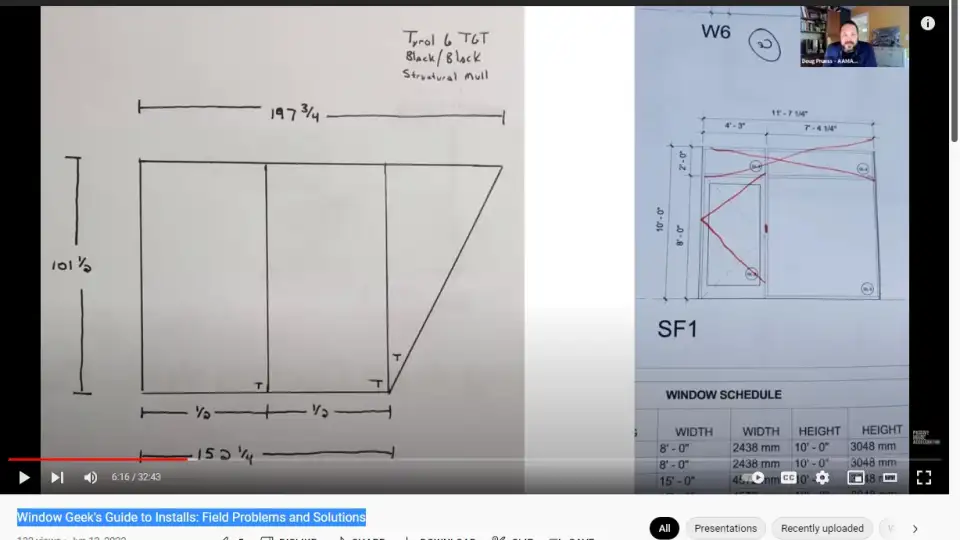

Let's see here. I got too many screens going on. Working on a lot of these for architects and builders. Basically, we're drawing things out, working with max sizes, which is the bane of everybody's existence. Really big openings and high efficiency are starting to be buzzwords we see all the time and trying to weigh the two out. There's no point of having huge amounts of glass if they don't meet structural requirements and fall over. So it's one of those of, I'd say if you're a designer or an architect, I would actually, instead of pulling things off the website, have a conversation with somebody and call that manufacturer, call that rep and run through it quick because what I've been seeing a lot lately is huge amounts of glass, where people are taking specs from different manufacturers and they're putting them together and they're making their project into a Frankenstein.

Hey, we want these blinds from Pella. We want this efficiency from Alpen. We want this kind of operating system on this window, and you shoot yourself in the foot before you even start a project. So I would definitely say, don't be shy, reach out, somebody will help you, and you'll get ahead of those problems right away. Max sizes are a big one, actually, even minimum sizes for a Passive House, a lot of people are making small windows for the wall area and sometimes you hit minimum sizes. So just stuff like that.

Also, on this other side, I don't know if you can see my pointer, where we're looking at projects where we're value engineering, where a lot of times, paying for a oversized window will actually cost less than putting two windows together because you're basically making two windows and then the mold cost of putting them together. And a lot of times, if you can make that window just a little bit oversized, if it's within the maximum sizes, that's a great way to save money. And you're going to learn that by talking with the manufacturer's rep.

I guess I'd have to preface this whole thing by saying, I'm not trying to sell anything here. So we're just going over what I do every single day and then just going through that. So apologies for not being polished on my PowerPoint skills.

There are many different product lines that could work in a high efficiency project. I personally would say, don't have the assumption that something from Europe is better because it really is not. The glass is glass, there's different coatings, but if you actually dig into it, a lot of manufacturers are owned by the same company. It's the stuff that's made in France is owned by the same company that they're making glass in the Midwest. And so I would say, try to get over that mystique of something in Europe is better.

Now, they're making windows differently where they're relying heavily on the frame and North American windows have traditionally relied on the glass. So small frames, large amount of glass, not focusing on air infiltration. But I do have conversations with large manufacturers that we're used to, the ones that advertise in the United States a lot, and talking with their R&D and their reps, and we'll talk about Passive House. And they'll ask the questions of... Well, sadly, the first question they ask is, "How many millions of dollars of windows can we sell if we make these windows?" And it's one of those things of you have the platform there, people want this to be more local. There are more local window manufacturers that are out there that are getting better and better.

But I would basically just say, anytime you're talking to a rep or something, bring up triple pane, high efficiency, and the more they hear it, the more they report to their higher ups. So if we're going to be wanting Anderson, Marvin, Pella to start being part of this conversation, I would say, let's quit discounting them. Let's quit, I guess, embarrassing them because we're going to eventually need them. We're not going to be able to import everything we want and we're going to want things to be built around here.

So I guess that's just my thought about that of pushing local manufacturers to be better, to design better because they can. They just don't want to make a window where they don't know anybody's going to buy it. And so groups like yours, where you see across the US and different countries where people are actually wanting these things, I look at it as almost capitalism. The more people that have it, it's going to drive the price down for you. Just like the Department of Energy R5 program that was a mess. But what they did is, they actually helped reduce the price of triple pane everybody. So that program was a mess, but it actually did do something with the manufacturers.

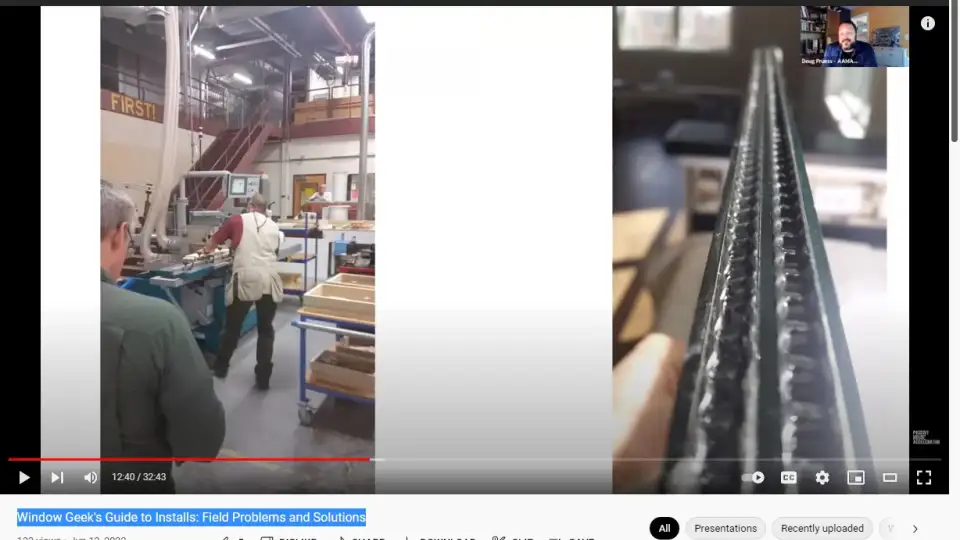

Moving on those slides here. This is actually funny enough a European component association came over to the US a handful of years ago and in a community college up in Wisconsin, they're trying to teach local manufacturers, regional manufacturers, how to make a Passive House tilt and turn. And this was actually meant for manufacturers, but sadly enough, it was me and another builder in a classroom, and that's all it was. So we started asking the questions of, are European windows better? What's the problem with North American windows? And all the obvious reasons we know, it's basically just down to IG depth and air infiltration. And he basically said, "American windows," like I said before, "rely heavily on the glass." European windows rely heavily on the frame. And we test at different points. So European U value is different than American U value. So comparing them side by side, it's not really apples to apples.

When you start seeing cross certifications, I mean, I've seen some European windows get certified by AAMA or an FRC, and they're touting a 0.12 U value, and testing on the American way, it ends up being a 0.18. And vice versa if you go over to Europe. So they don't talk. Somebody smarter than me can help you with the calculations. But even those people that know those calculations, it's never cut and dry.

Consulting and then installing and services is the things that I end up doing, and that's how I split this out. This is a cool project down in Texas where we're making it higher efficiency and I'm actually going down there next week to help install this bifold door in this opening. So going across state, working with people all around, this is a fantastic project down there. And I'm more than happy to help. And actually, we're actually getting service techs in Texas to come out and teaching them how to put in a bifold door correctly, because problems with things like bifold doors, not even an efficiency standpoint. There are bifold doors out there now that have air infiltration ratings of 0.06. So I would say any preconceived notions that you have, throw them out the window, literally, because I tell architects to dream big and let me reel you back. Just keep going, just keep going and then we can reel you back in.

I don't have a love lost for any one certain product line. That's why I use over 30. So every project just has a different need. And every product can fulfill that need. So doing installations, this is some in Northern Illinois where an apartment building, we're actually installing fiberglass doors from Canada. That manufacturer is Inline. It's a great fiberglass product. I'm a huge fan of fiberglass. Fiberglass, it's technically thermally inert. It's the same molecular makeup as glass. So it moves at the same rate. Its longevity, you can throw fiberglass window in a lake and the glass is going to blow before the frame degradates. We're using fiberglass reinforced concrete, we use it on holes in boats.

And one of the biggest problems with fiberglass can be price because it takes so many tons of force to pull these fibers through a die, and those dies are really expensive. So you'll see fiberglass windows be more basic. But when we're looking at, say a European import to North America, the Inline is actually starting to export fiberglass windows to Europe. So now we're starting to go both ways, which I like to see, just mixing European innovation and North American innovation also.

So this is just more of your basic install. There was not a lot of high efficiency on this project, but like I said, we could put a aluminum system in here, but we actually were able to get the framing on this whole apartment complex through these patio doors, we actually get an anodized paint and it actually looked like an aluminum storefront. So now we have high efficiency with fiberglass and we're matching the style, so it didn't look like an eyesore. I don't know if you can see the entry system over here, this anodized paint, it's just simple things where you don't have to overthink.

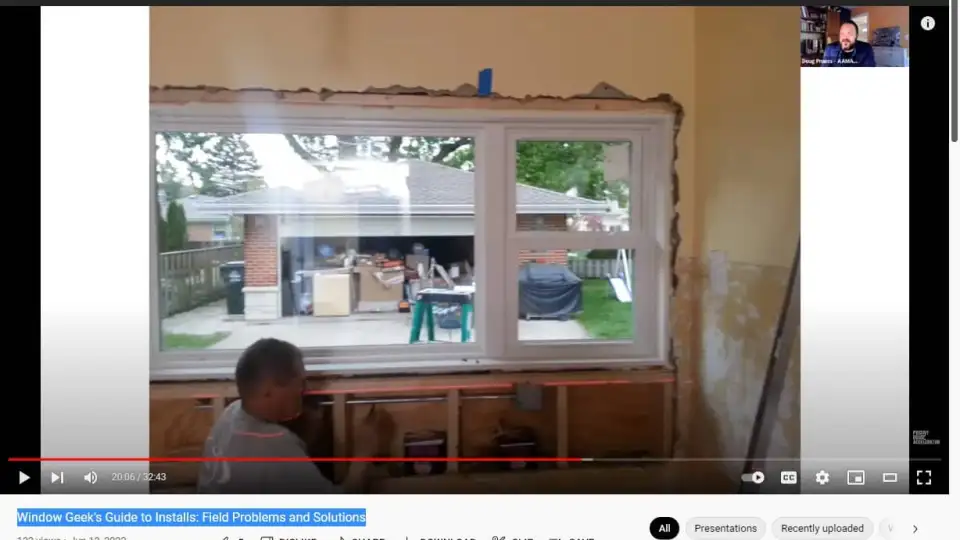

We do install contracts for a lot of different manufacturers. And this one's just your basic one from say Anderson, and nothing crazy about this project. This is just your basic kind of stuff. But even in a basic house, installing a window correctly, to me it's pinnacle just because windows are going to be your first horizontal surface and they're going to be the ones that will show a problem, even though it may not be the window. If some water or mass or air or anything gets through... Not air. If water gets through, it's going to hit the first horizontal surface and your windows are going to be the ones that show it.

This is from some of the crews. We're actually starting to get a little bit more traction with say European tilt and turns, at least say in the Midwest area. Not a lot, not a lot of people know about it. Somebody will say something about coming from Europe, that they visited one time and they had those funny windows that swung in. So just trying to get the proper install along with the proper training from certain guys.

Funny story about this photo. This was actually a photo for a TV series called Kitchen Crashers, where I did about five episodes with them on HGTV. It's not fun to work on a TV show. I'm not going to lie. It's, hey, show up at seven in the morning with your window. And honestly, on this project right here, it was for a Chicago fireman, and I literally sat in the neighbor's garage with them, waiting for them to call me over. And they're just sitting there having beers all day, just joking around like a bunch of firemen. And I was supposed to sit there and install a window. I got there at eight in the morning. We didn't install the window until eight o'clock at night. So it was all of that for just putting in one window.

So, that's just a fun... Let's see here. You would never think you would need a welder while you're installing windows, but every once in a while, you come across something like this. Now, these are not high efficiency details. This is just putting higher efficiency windows into an opening, and funny enough, just learning how to weld in shop class in high school was enough to make this window work. So this is one of those things where you just come across odd situations.

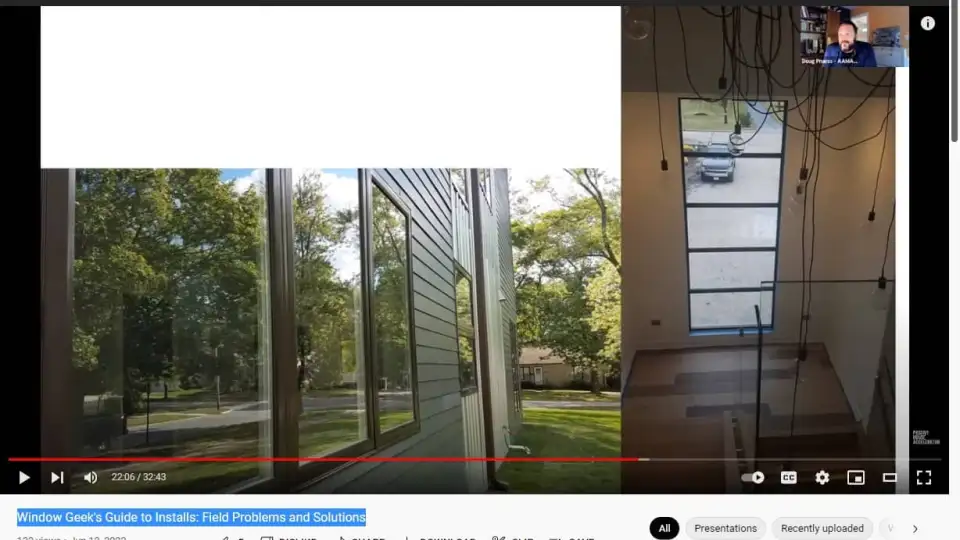

This is a bi-parting patio door. It hasn't been taped up or anything yet, I'm just showing project photos. I think these were a Pella window that we put in recently. Black on the interiors, kind of a big deal recently. I show these for different product clients. So if you're looking over here on the right, this is a whole house that was done in a very contemporary fashion. We put triple pane in it. We're not saying the efficiency was crazy. It was a U value of 0.20. But honestly, it initially got specked out, not even to meet code. So it's just paying attention. Some builders don't even pay attention to that. And if you can push forward and say, "Hey, let's at least do minimum Energy Star. Let's talk about triple pane." When you have so much glass in a house, it can make a big difference.

So something like the one on the right, that looks like a steel window. That's actually an aluminum clad window. Different product lines. This is a cellular PVC window that was done in Westmont, Illinois. And that was one of those where we didn't want do vinyl. They couldn't quite afford fiberglass, and knowing that there's so many manufacturers out there that we were able to find a high efficiency cellular PVC. I wish some of these frame manufacturers actually cared about passive a little more. I'm trying to champion that where we can do high efficiency frames in something that's already made and actually start talking about high solar heat gain glass, things like that. But again, it kind of gets down to what is needed out in the market and what a manufacturer's going to push out.

Different photos of different projects that we've done. Different installation is needed. Obviously, you can see by the barriers and the rip in the Tyvek that this is not another high efficiency. When it comes to supply, I would say, sadly about half of the stuff I do is dual pane just because of what's needed for the project. But there was a couple years for installation where we were able to say that 80% of our projects were 0.20 or better. So that's something that we look forward to. Installers sometimes can get a little grumpy about it, because they're a little bit heavier, but the more you do, the more they get used to it.

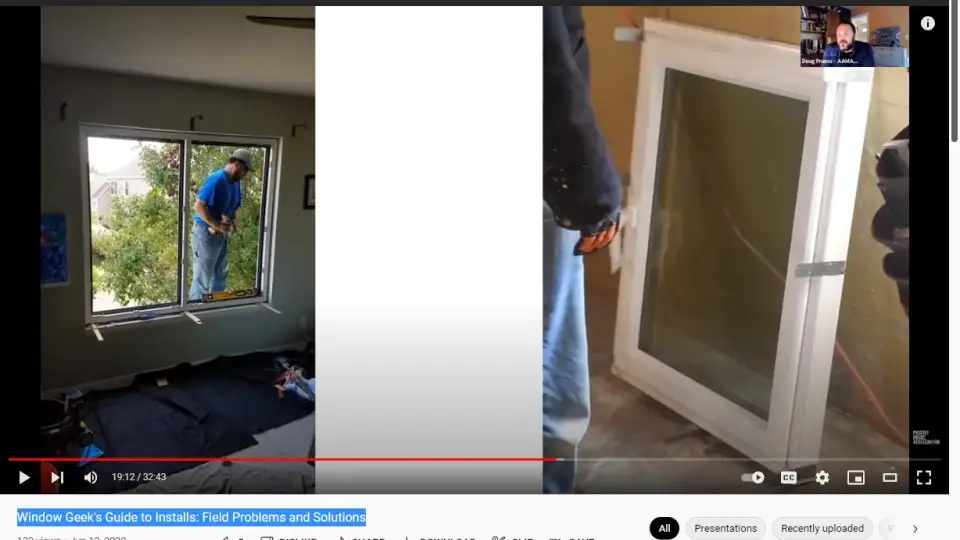

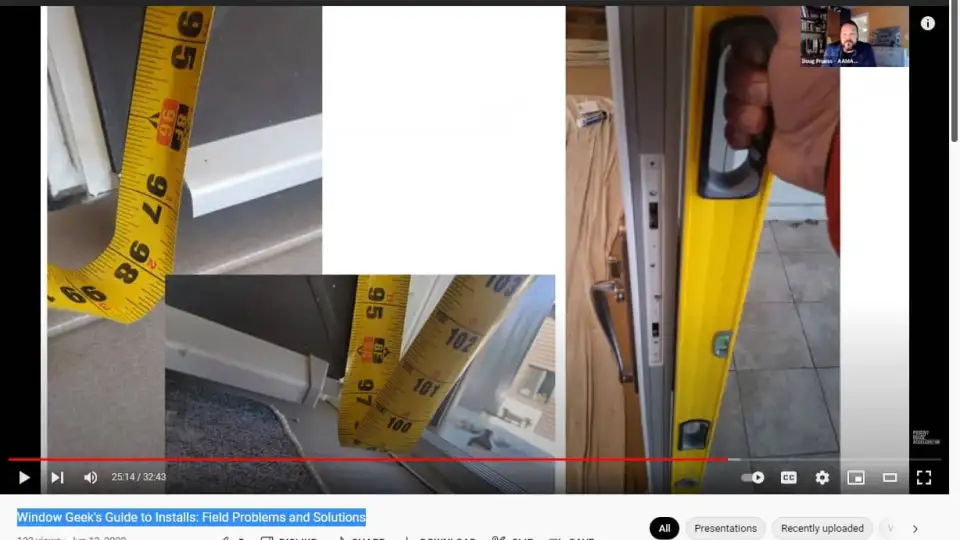

Basically, just taking advantage of the view, clean workspace, things like that. And then the last thing that I do is, I run service and service contracts for manufacturers. So going to the job site, figuring out problems and just remedy them. I like to tell homeowners, builders, architects, and everything that a lot of times, windows, if they're installed properly, square, plum and level, that any kind of problem that's out there, usually doesn't have to result in a reinstall. It results in just changing out, basically like a car, OEM parts. If your alternator goes bad, we can change the alternator. Everything still works. So here's examples of a window frame where, first thing we do is make sure that it's proper installation. But even if the install is a little bit off, it doesn't mean a service tech can't fix it.

You can max out hardware like a tilt and turn has many points of adjustment and there's plenty of projects we've done where you can go around and adjust everything without doing any kind of reinstallation. Like this one, this panel, if you're measuring corner to corner on this, it was actually over a half inch off. And we were wondering why the homeowners kept getting locked into their home. So that was a manufacturing error and a new sash got sent out and reinstalled. So again, not the end of the world, but when we're trying to create a cohesive group of say the manufacturer, the architect, the builder, the homeowner, as long as there's communication, as long as everybody works together, majority of the time, this stuff can get fixed without a lot of arguments.

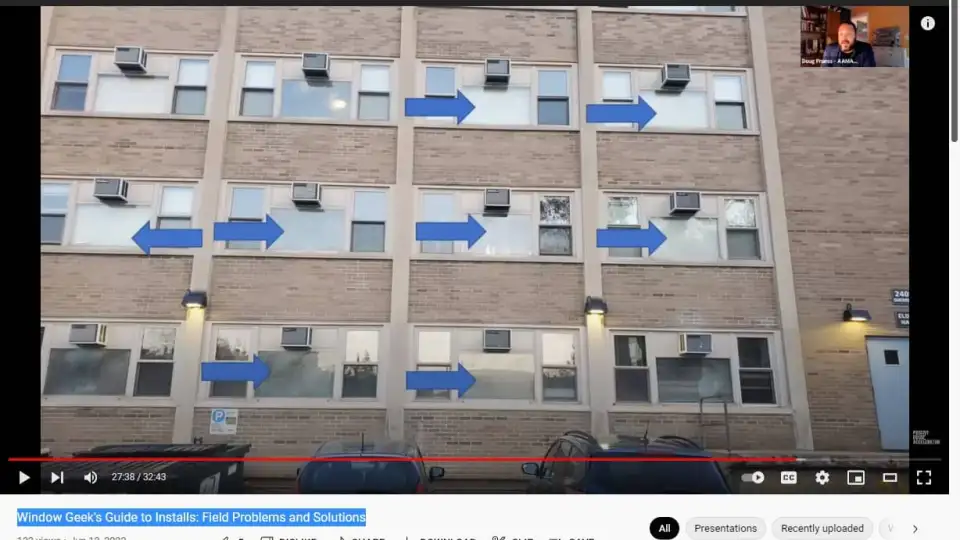

This is just musings of Doug. I actually went to a Northwestern football game and we're walking out and we're walking in the alley and I noticed this and it just popped in my head that needed to be a photo and talked about. So everything where the arrows are, those are glass panels that are blown. When you blow a glass panel, you don't have anything more than whatever air barrier that glass is. Maybe because of the film, you're going to have maybe an R1. So blown seals lead to bad efficiency, obviously.

But when you're looking at projects like this, and when you're designing projects like this, I'm not going to do a Q&A about it. I'll just go to where I came in is, when you're looking at this, why are all those glass panels blown? Why are we leading to early failure? Because of design. This is terrible design. All the air conditioning units are above it. They're vibrating on top of a glass panel and the glass panels are blown. So the design on this one was, it looked great. It served a purpose, but longevity-wise that vibration from those air conditioners blew out all the glass panels. So now, I don't know, that's probably not going to be a warranty thing, but just something to think about of when you're designing.

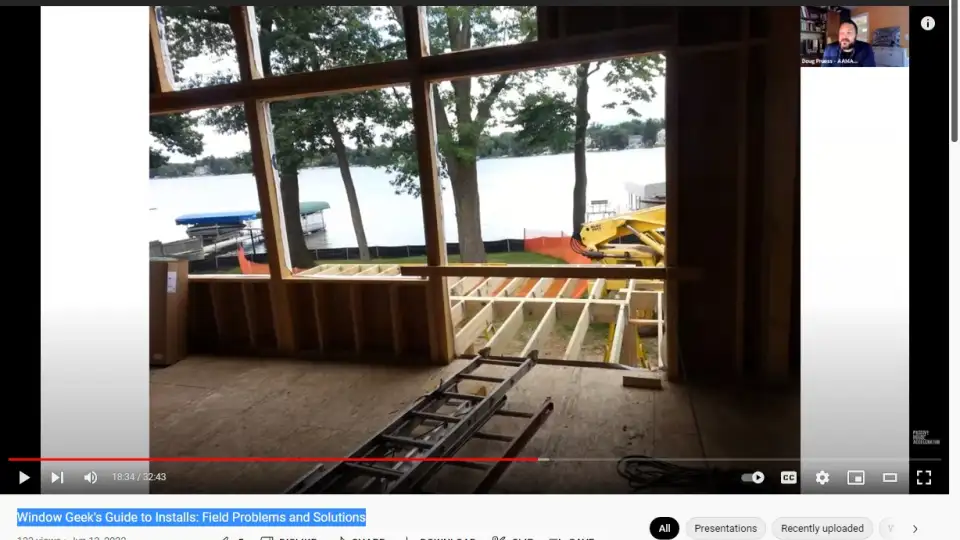

Getting toward the end here, if you're just paying attention, the obvious things are the best, and something as simple as you look at this whole project here being built, they're actually using some triple pane, double-hungs from Pennsylvania where you think double hung windows air infiltration-wise are the worst, usually are. But there are manufacturers say like this company where their air infiltration is a 0.01 CFM per square foot. That's tighter than say a Pella casement.

If you're looking at specs from different manufacturers, some manufacturers don't even know what... They tout their air filtration, but they don't realize how big of a deal it is. So, but this is from a service aspect. Looking at this apartment building, it was just doing a site check walking around. That sticker being upside down raised some alarms. So went over there, actually inspected it, realized that it actually was put upside down. The problem with that is, all your weep poles are on the top and not on the bottom and so all the water is going to flow to the inside.

These guys are doing a great job. They did a great job doing flashing too. Overlapped the top flashing, system components were put together correctly. They did a great job doing sill pans. Just overall, just great spec product, but then spec product, great install, and then you're just going to get that one guy that maybe nobody's paying attention or thinking about it. And you got a window upside down. It's going to lead to longevity issues in the window and in that wall.

It gets rounded out because just like I was telling Mark and everybody that this is just more of a conversation. There's really nothing to sell. It's just what I do day-to-day and just trying to take the mystique out of windows and not being afraid of them. But they're so integral in what we do. Windows are part of the interior, the exterior, the heating, the cooling, the lighting, the ventilation, air barriers. It's almost a piece of furniture in a lot of homes. And the sad thing is, is that you'll see a lot of homes that would rather have that Wolf range in their kitchen, and they're going to cheap out on the windows.

And it's just sad where you walk into these homes that are a million, $2 million, and you see them putting in $150 vinyl windows. You're almost telling the homeowner, "If I could buy you something cheaper, I would." So it's just really trying to integrate efficiency, not trying to have service problems, that kind of thing. But windows are important and installations of windows are also. So that was my just short, quick presentation with some photos, things like that.

And when I was talking there in the prep session, we decided not to go into a lot of the details because you guys are having somebody on here soon from my understanding where you guys are doing the details. So this one's going to more be for service, product selection, things like that where again, I don't work for any one manufacturer. It's just what manufacturer fits this project the best?

Related Videos

6/1/22

A Developer’s Perspective: Transforming Communities with Passive House

Video, Affordable Housing, Multifamily, PHA Live

5/16/22

Top Ten Ways to Know You Are Buying Quality Windows, with Sam McAfee, Zola Windows

Video, Fenestration, PH Component Spotlight

1/24/20

What Should You Know About Passive House Windows with Ben Leer

Video, Fenestration